Desulfurization dust removal deep cooling exchange all-in-one machine

A desulfurization and dust removal, all-in-one technology, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of low heat exchange efficiency, waste of energy, inability to recover, and large structure, and achieves simplified structure and reduced heat exchange. The effect of improving efficiency and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

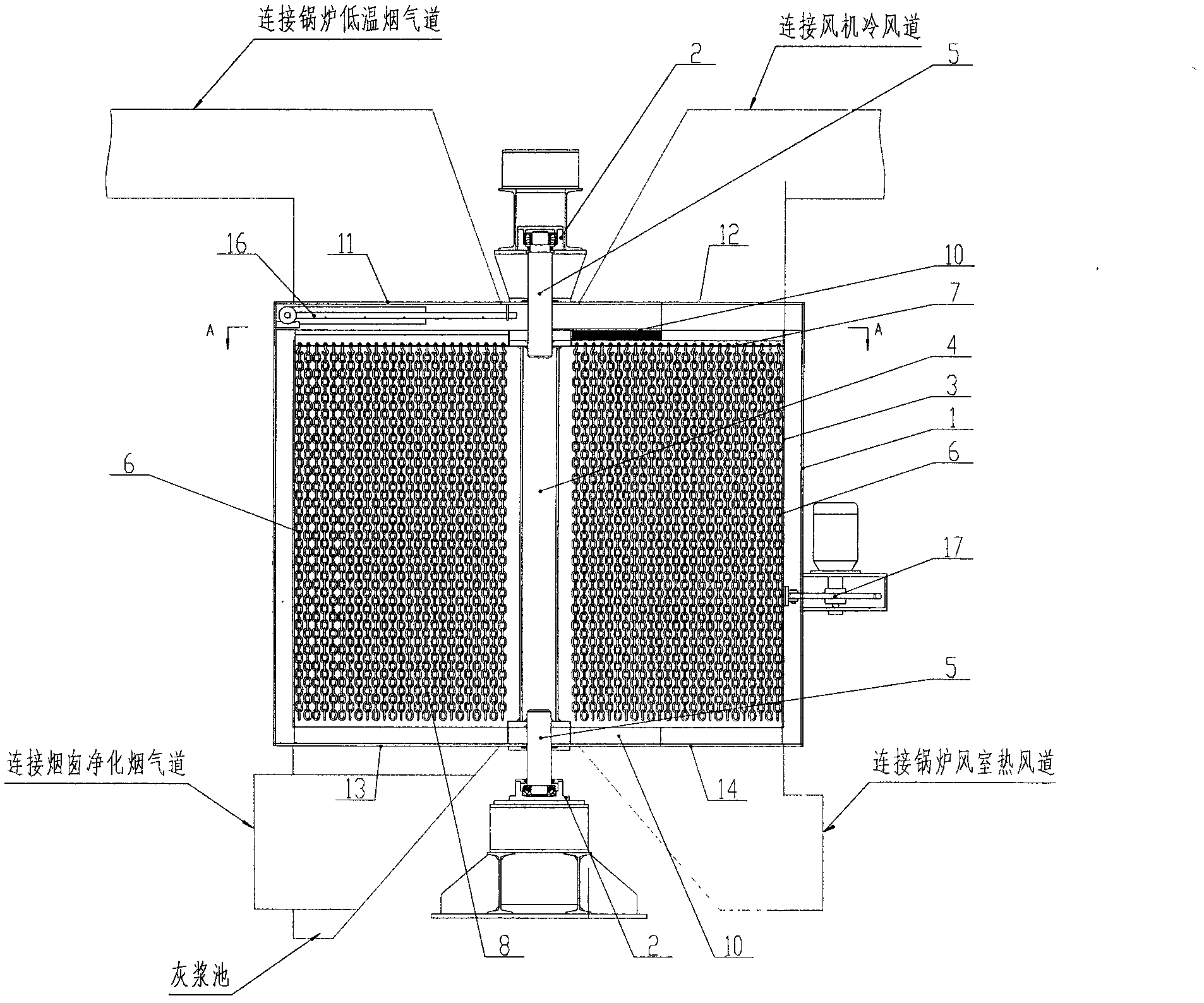

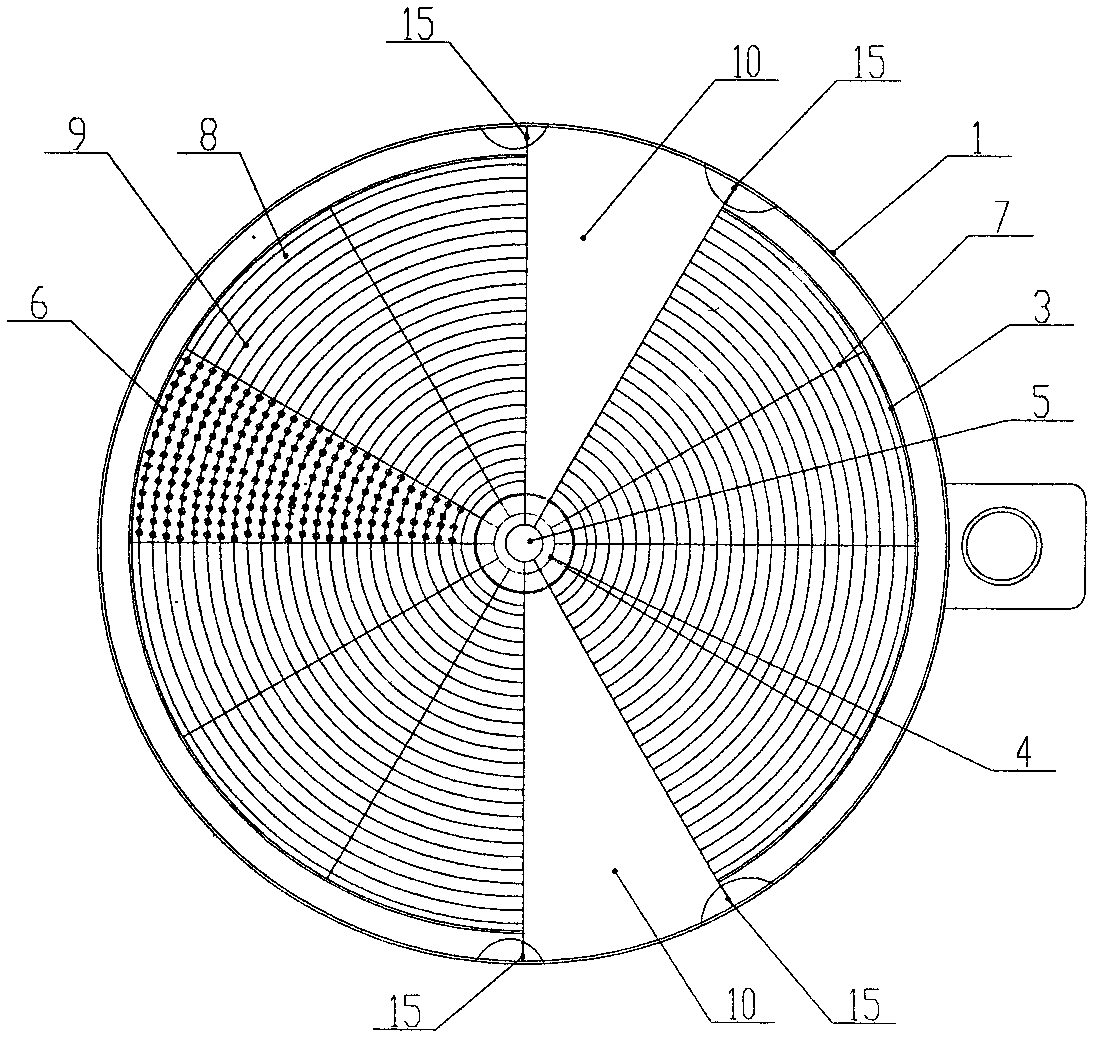

[0009] Provide preferred embodiment of the present invention below in conjunction with accompanying drawing: it is made of stainless steel by vertical fixed cylindrical body 1, the vertical rotary body placed in vertical fixed cylindrical body 1 and upper and lower bearing blocks 2 and lime water spray The device is composed of: the vertical rotary body is made of stainless steel by the vertical rotary cylinder 3, the vertical sleeve 4 placed in the center of the vertical rotary cylinder 3 is made of stainless steel, the upper and lower rotary vertical shafts 5 and the heat carrier ring chain 6. The material is made of stainless steel. The upper and lower ends of the vertical sleeve 4 are fixed with the central shaft seat of the rotary body. The material is stainless steel. , the key pins are fixed, in the vertical rotary cylinder 3, surrounding the vertical sleeve 4, vertical partitions 7 are evenly distributed according to the isocenter angle, and the material is stainless st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com