Surface layer whitewash gypsum using dry-process desulfurized ash as raw material and preparation method thereof

A technology of dry desulfurization ash and plaster plaster, which is applied in the field of building materials, can solve problems such as environmental pollution and land occupation, and achieve the effects of high strength, good water retention performance, and excellent construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

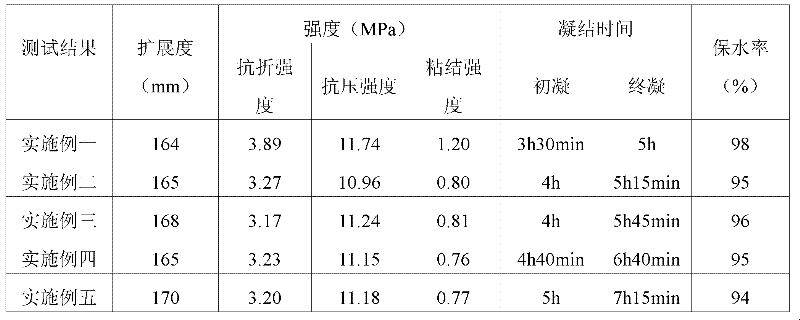

Examples

Embodiment 1

[0019] By weight, weigh 60 parts of calcined desulfurized gypsum powder, the specific surface area is 330m 2 / kg, 10 parts of dry desulfurization ash, density 2.56g / cm3, gypsum retarder animal protein sodium salt (commercially available Suzhou Xingbang retarder SG) 0.5 part, water retaining agent hydroxypropyl methyl cellulose ether (HPMC) 0.2 parts, viscosity is 60,000 mpa.s, binder ("Wacker" 5044) 0.2 parts of vinyl acetate-ethylene copolymer latex powder, 30 parts of Shuangfei powder with a fineness of 350 mesh, put them into the mixer, and mix for 10 minutes to prepare the surface layer plaster dry powder.

Embodiment 2

[0021] By weight, weigh 55 parts of calcined desulfurized gypsum powder, the specific surface area is 380m 2 / kg, 25 parts of dry desulfurization ash, density of 2.42g / cm3, 0.6 part of gypsum retarder sodium citrate, 0.1 part of water retaining agent methyl cellulose ether (MC), viscosity of 60,000 mpa.s, bonding agent ("Yi Lai Tai" FL4200) 0.2 parts of vinyl acetate-tertiary carbon vinyl ester-acrylate copolymer latex powder, 20 parts of Shuangfei powder with a fineness of 400 mesh, put them into the mixer, and mix for 10 minutes to prepare the surface layer plaster dry powder.

Embodiment 3

[0023] By weight, weigh 40 parts of calcined desulfurized gypsum powder, the specific surface area is 420m 2 / kg, 40 parts of dry desulfurization ash, density of 2.48g / cm3, 0.7 part of gypsum retarder sodium polyphosphate, 0.2 part of water retaining agent hydroxyethyl methyl cellulose ether (HEMC), viscosity of 80,000 mpa. s, binder (Shanxi Sanwei SWF-05) 0.1 part of polyvinyl acetate-vinyl carboxylate-ethylene copolymer latex powder, 20 parts of Shuangfei powder, the fineness is 300 mesh, put into the mixer, mix for 10 minutes, and prepare noodles Layer plaster dry powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com