Process for treating organic silicon slurry slag

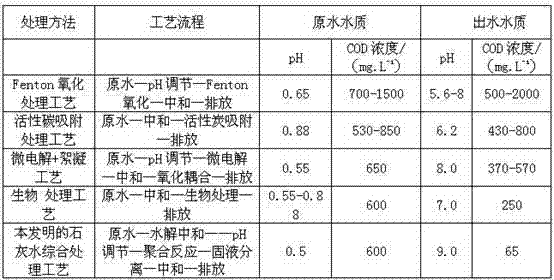

A treatment process, organic silicon technology, applied in the direction of cement production, solid waste removal, etc., can solve environmental pollution, incomplete treatment of clean waste, complicated and other problems, and achieve the effect of solving air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, organosilicon slurry slag processing technology, wherein:

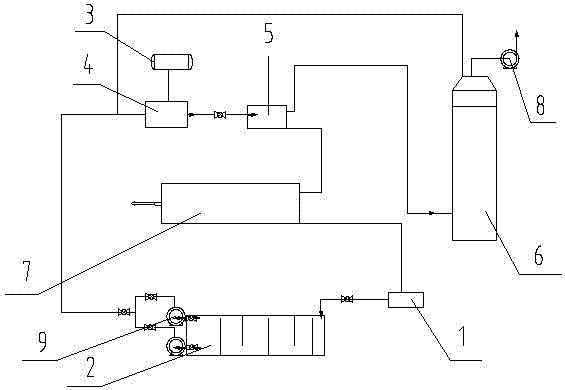

[0030] The devices involved in the organosilicon slurry treatment process are as follows: the sewage station 1 is connected to the lime pond 2 through pipes, the lime pond 3 is connected to the slurry slag treatment reactor 4 through pipes; the slurry slag treatment reactor 4 is connected to the slurry slag tank through pipes 3 is connected; the slurry residue treatment reactor 4 is connected with the hydrolyzate collection tank 5 through the pipeline; the hydrolyzate collection tank 5 is connected with the oil collection tank 7 through the pipeline, and is also connected with the absorption tower 6; the oil collection tank 7 is connected with the sewage through the pipeline The station 1 is connected to each other; the top of the absorption tower 6 is also provided with an induced draft fan 8; The pipes are connected to the upper part of the absorption tower 6 through branch pipes.

[0031] The ...

Embodiment 2

[0040] Embodiment 2, organosilicon slurry slag treatment process, wherein: organosilicon slurry slag treatment process is:

[0041] The water discharged from the sewage station 1 is pumped into the lime tank 2 through the pump, the lime is dissolved into lime water, the pH is adjusted to 9, and the lime water is pumped into the slurry slag treatment reactor 4 through the mortar pump 9;

[0042] The slurry slag tank 3 is connected to the slurry slag treatment reactor 4, then nitrogen is added to the slurry and the slag is pressed to 0.03MP, and the slurry slag is pressed into the slurry slag treatment reactor 4 for reaction;

[0043] The lime water is continuously flowing into the slurry and residue treatment reactor 4;

[0044] Control the reaction temperature at 60°C;

[0045] When the organic silica slurry slag encounters alkaline water, a violent hydrolysis reaction occurs and polymerization occurs, so the mixture of sand-like solid particle product and liquid is obtained;...

Embodiment 3

[0049]Embodiment 3, the treatment process of organosilicon slurry slag, wherein: the treatment process of organosilicon slurry slag is

[0050] The drainage from the sewage station 1 is pumped into the lime tank 2 through the pump, the lime is dissolved into lime water, the pH is adjusted to 8, and the lime water is pumped into the slurry slag treatment reactor 4 through the mortar pump 9;

[0051] The slurry slag tank 3 is connected to the slurry slag treatment reactor 4, then nitrogen is added to the slurry and the slag is pressed to 0.03MP, and the slurry slag is pressed into the slurry slag treatment reactor 4 for reaction;

[0052] The lime water is continuously flowing into the slurry and residue treatment reactor 4;

[0053] Control the reaction temperature at 100°C;

[0054] When the organic silica slurry slag encounters alkaline water, a violent hydrolysis reaction occurs and polymerization occurs, so the mixture of sand-like solid particle product and liquid is obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com