Plastic steel building template

A technology of building formwork and plastic steel, which is applied in construction, building structure, formwork/formwork components, etc., can solve the problems of rough concrete surface, easy rust of formwork, easy peeling of cement or paint, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Open and manufacture plastic-steel building formwork in-mold injection molding molds

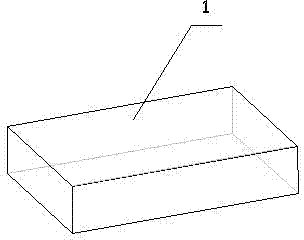

[0019] 2. Make a metal template

[0020] 3. Making plastic-steel building formwork

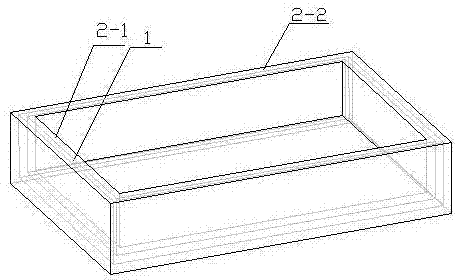

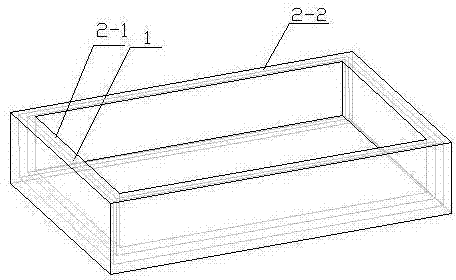

[0021] Put the metal template (1) into the mold of the injection molding machine, use PET plastic particles (ie 2-1, 2-2 in the figure) to injection mold the plastic steel building template in the mold of the injection molding machine, and control the mold during injection molding The mold cavity temperature is 85°C, the molding temperature is 260°C, the molding pressure is 50Mpa, and the molding cycle is 1.5min.

Embodiment 2

[0023] 1. Open and manufacture plastic-steel building formwork in-mold injection molding molds

[0024] 2. Make a metal template

[0025] 3. Making plastic-steel building formwork

[0026] Put the metal formwork (1) into the mold of the injection molding machine, use PA plastic particles (ie 2-1, 2-2 in the figure) to injection mold the plastic-steel building formwork in the mold of the injection molding machine, and control the temperature of the mold during injection molding The mold cavity temperature is 80°C, the molding temperature is 270°C, the molding pressure is 60Mpa, and the molding cycle is 1.2min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com