Method for whitewashing filler wall

A technology for filling walls and mesh cloth, applied to walls, coverings/linings, buildings, etc., can solve the problems of easy cracks and different shrinkage rates, and achieve the effect of reducing surface cracks and avoiding secondary maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with specific embodiments.

[0020] The whitewashing method of filling wall of the present invention is as follows:

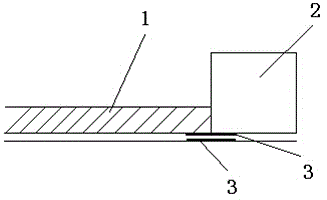

[0021] 7 days after the masonry of the filling wall in the frame project is completed → plaster the ash cake → after the joints of the beams, columns (that is, the frame structure 2) and the filling wall 1 are blocked with expanded fine stone concrete, lay a layer of alkali-resistant mesh cloth 3 (distance The lap joint width of the seam side is not less than 150mm) → the first bottom copying and maintenance → the bottom copying is 70% dry, and the second layer is the surface layer construction. Lay a layer of grid cloth 3 on the surface of the mortar at the junction of the column and the filling wall, the paving method is the same as before → calender the surface with an iron trowel, press the alkali-resistant mesh cloth into the cement slurry → maintain the whitewash layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com