Preparation method of prismatic biological calcium carbonate

A bio-calcium carbonate, prismatic technology, applied in the directions of fibrous filler, dyeing physical treatment, dyeing organosilicon compound treatment, etc., can solve the problems of poor matrix compatibility, uneven dispersion, poor surface modification effect, etc. The effect of good capacity, uniform dispersion and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The steps of the preparation method of prismatic biological calcium carbonate are as follows:

[0022] 1) After washing the shells with water to remove the residue, soak them in 0.05-0.75 mol / L sodium hydroxide solution, potassium hydroxide solution or sodium hypochlorite solution at 25-100 °C for 5-120 minutes, and wash to remove the cuticle;

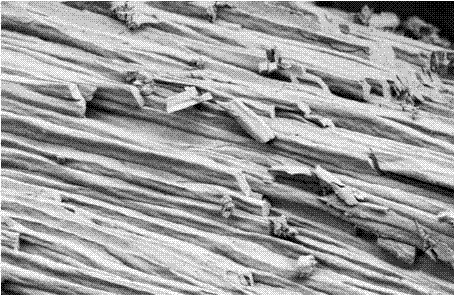

[0023] 2) Soak the shells from which the horny layer has been removed in 0.3-5 mol / L sodium hydroxide solution or potassium hydroxide solution for 30-180 minutes at 50-200 °C, then wash with drum to separate the shell prismatic layer and shell nacre layer, Obtaining the shell prism layer, crushing the shell prism layer to 100-400 mesh;

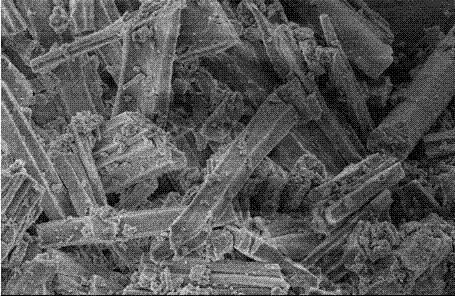

[0024] 3) Mix the pulverized shell prismatic layer powder with water and grinding aid, and stir to obtain a slurry. The quality of the shell prismatic layer powder is 10% to 50% of the water mass, and the grinding aid The quality of the agent is 0.25% to 5% of the quality of the shell prism lay...

Embodiment 1

[0034] 1) After washing the mussel shells with water to remove the residue, soak them in 0.75 mol / L sodium hydroxide solution for 120 minutes at 25 °C, and wash with water to remove the cuticle;

[0035] 2) Soak the cuticle-removed sample in 5 mol / L sodium hydroxide solution at 50 °C for 180 minutes, wash with a drum to separate the shell prism layer and shell nacre layer to obtain the shell prism layer, and use the conventional crushing method to crush the shell The prism layer is crushed to 100 mesh;

[0036] 3) Mix the pulverized shell prism layer powder with water and grinding aid polyacrylic acid, and stir at a high speed to prepare a slurry; the quality of the shell prism layer is 10% of the water quality, and the grinding aid's The mass is 0.25% of the shell prismatic layer mass;

[0037]4) Using zirconia balls as the grinding media, put the grinding media with particle sizes of 0.5 mm, 1.5 mm, and 2.5 mm into the grinding bucket according to the mass ratio of 3:2:1. ...

Embodiment 2

[0041] 1) After washing the scallop shell with water to remove the residue, soak it in 0.75 mol / L potassium hydroxide solution for 5 minutes at 100°C, and wash with water to remove the cuticle;

[0042] 2) Soak the cuticle-removed sample in 0.3 mol / L potassium hydroxide solution at 200 °C for 30 minutes, wash with a drum to separate the shell prism layer and shell nacre layer to obtain the shell prism layer, and use the conventional crushing method to crush the shell The prism layer is crushed to 400 mesh;

[0043] 3) Mix the pulverized shell prism layer powder with water and the grinding aid sodium silicate, and stir at a high speed to obtain a slurry. The quality of the shell prism layer is 50% of the water quality, and the grinding aid The mass of the shell is 5% of the mass of the prismatic layer;

[0044] 4) Using ceramic balls as the grinding media, put the grinding media with particle diameters of 1 mm, 2 mm, and 3 mm into the grinding bucket according to the mass rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com