Method for preparing regenerated cellulose spherical aerogel modified through carboxylation

A technology of regenerated cellulose and carboxylation, applied in chemical instruments and methods, inorganic chemistry, chemical recovery, etc., can solve the problems of weak adsorption performance of cellulose airgel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

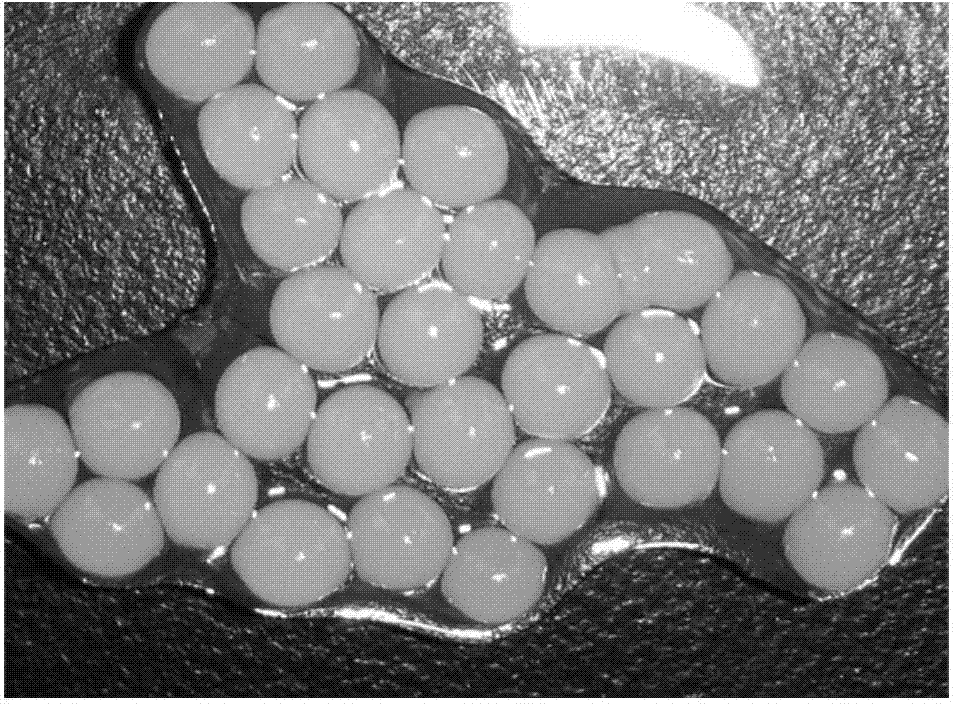

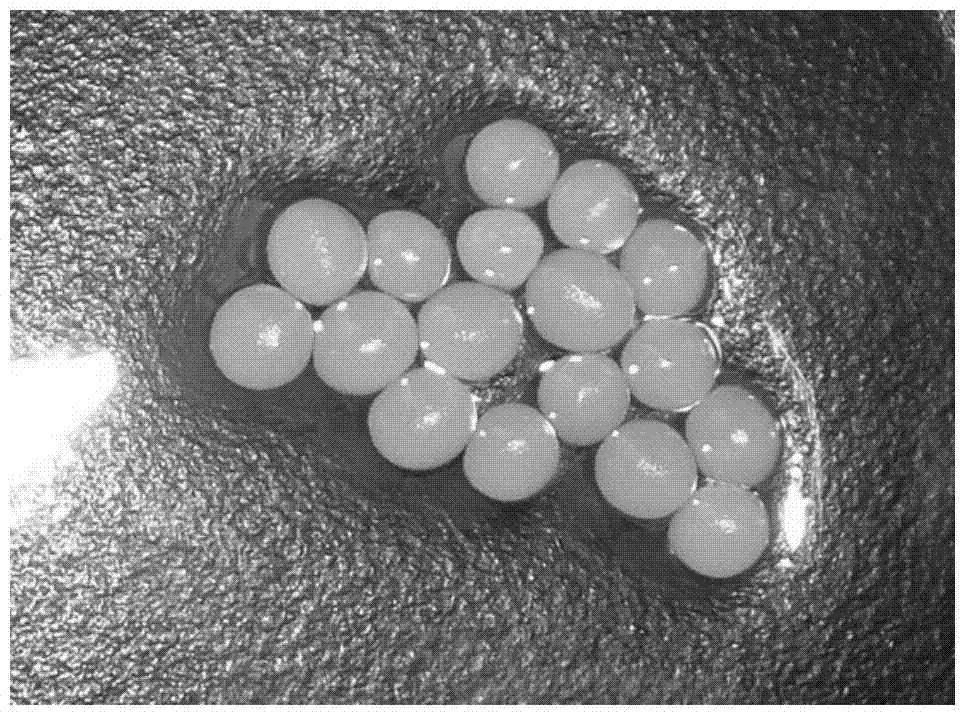

[0024] Specific embodiment one: the preparation method of carboxylated modified regenerated cellulose spherical airgel in this embodiment is implemented according to the following steps:

[0025] 1. According to the mass ratio (6~7): (10~12): (70~81), mix sodium hydroxide, urea and deionized water, add cellulose raw materials at a temperature of -15~-12°C, After stirring and dissolving, the insoluble precipitate was removed by centrifugation to obtain a cellulose solution, and then the cellulose solution was added dropwise to the regeneration solution with a dropper, and the spherical hydrogel was collected after solidifying in the regeneration solution for 5 to 15 minutes. Washing with deionized water for 3 to 5 times and soaking in deionized water to obtain regenerated cellulose spherical hydrogel for use;

[0026] 2. Dissolve 1~1.5mg TEMPO (2,2,6,6-tetramethylpiperidine-1-oxyl) and 10~15mg sodium bromide into 30~50mL deionized water, add 10~20g step 1 The obtained regenera...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment differs from Embodiment 1 in that step 1 mixes sodium hydroxide, urea and deionized water in a mass ratio of 7:12:81. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the cellulose raw material in step 1 is bamboo fiber, and the cellulose mass fraction of bamboo fiber is 98%. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com