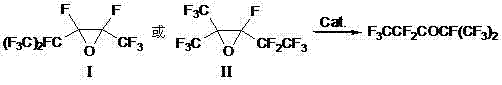

Preparation process of perfluoro-2-methyl-3-pentanone

A preparation technology, methyl technology, applied in the field of preparation technology of perfluoro-2-methyl-3-pentanone, to achieve the effect of high efficiency of reaction equipment, easy operation and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Synthesis of perfluoro-2-methyl-2,3-epoxypentane by continuous liquid phase epoxidation

[0038] Follow these steps:

[0039] a. Prefabricate 164.7kg of newly prepared sodium hypochlorite solution with an available chlorine content of 16.98%, add 19.7L of acetonitrile, mix well to make a sodium hypochlorite-acetonitrile solution, and weigh 98.6kg (0.329kmol) of 97.4% perfluoro-2- Methyl-2-pentene, the perfluoro-2-methyl-2-pentene of the present invention is obtained by telomerization and isomerization of hexafluoropropylene by a known method;

[0040] b. After measuring the sodium hypochlorite-acetonitrile solution and perfluoro-2-methyl-2-pentene according to the ratio with a metering pump, cool them to about -10°C through the second heat exchanger and the first heat exchanger respectively After that, it is continuously sent to the mixer for mixing;

[0041] c. The mixed reaction materials in the mixer are continuously sent into a pipeline-type liquid phas...

Embodiment 2

[0047] The continuous liquid phase epoxidation method synthesizes perfluoro-2-methyl-2,3-epoxypentane according to the following steps:

[0048] The method operation identical with embodiment 1, difference is that sodium hypochlorite quality is 163.3kg, and available chlorine content is 17.11%, and acetonitrile consumption is 19.7L, and perfluoro-2-methyl-2-pentene consumption is 98.6kg (0.329 kmol) content is 98.21%, and the reaction temperature is 0°C.

[0049] Results: The quality of the crude epoxide was 99.2kg (0.314kmol), the content was 97.83%, and the yield was 95.14%.

Embodiment 3

[0051] The continuous liquid phase epoxidation method synthesizes perfluoro-2-methyl-2,3-epoxypentane according to the following steps:

[0052] The same method operation as in Example 1, the difference is that the quality of sodium hypochlorite is 164.6kg, the available chlorine content is 18.03%, the amount of diethylene glycol dimethyl ether is 22.6L, perfluoro-2-methyl-2-pentene The dosage is 113.3kg (0.329kmol) and the content is 98.21%.

[0053] Results: The quality of the crude epoxide was 114.2kg (0.356kmol), the content was 97.62%, and the yield was 95.12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com