Salt-free dyeing method of vinyl sulphone type reactive dye for cotton fiber

A technology of salt-free dyeing and reactive dyes, which is applied in dyeing, textiles and papermaking, etc., can solve the problems of high cost, complicated process, and wearability of dyed fabrics (breathability, moisture permeability and tearing strength decrease, etc.) to improve the utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

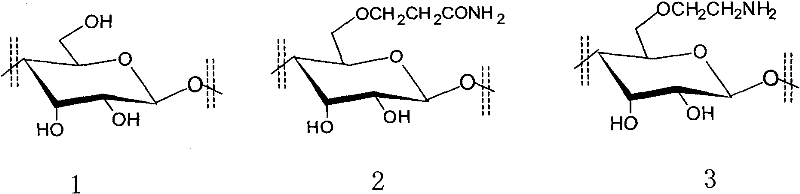

[0018] (1) Cotton fiber modification route

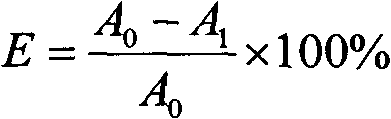

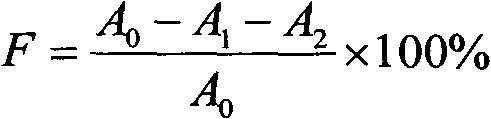

[0019] Two dipping and two rolling, the excess rate is 100%. The solution used for padding is an aqueous solution of acrylamide and sodium hydroxide. The solution composition is: 20% (mass percentage, the same below) acrylamide, 1.65% sodium hydroxide, sub Sodium nitrate 1‰, put the padded cotton fiber in a constant temperature box at 70°C for 2h, take it out and cool it to room temperature, wash it until neutral, put the above cotton fiber into 40°C sodium hypochlorite and sodium hydroxide aqueous solution for 1h, The bath ratio is 1:30, the composition of sodium hypochlorite and sodium hydroxide aqueous solution is: available chlorine is 0.9%, and the pH value is 12. Take it out and wash it until neutral, soak it in an acetic acid solution with a pH value of 4.5 for 30 minutes, and wash it with water until neutral.

[0020] (2) Dyeing process route and prescription

[0021] Reactive Black KN-B or Reactive Brilliant Blue KN-R, th...

Embodiment 2

[0026] (1) Cotton fiber modification route

[0027] Two dipping and two rolling, the excess rate is 105%. The solution used for padding is an aqueous solution of acrylamide and sodium hydroxide. The solution composition is: 20% (mass percentage, the same below) of acrylamide, 1.65% of sodium hydroxide, Sodium nitrate 1‰, put the padded cotton fiber in a constant temperature box at 70°C for 2h, take it out and cool it to room temperature, wash it until neutral, put the above cotton fiber into 40°C sodium hypochlorite and sodium hydroxide aqueous solution for 1h, The bath ratio is 1:30, the composition of sodium hypochlorite and sodium hydroxide aqueous solution is: the available chlorine is 0.9%, and the pH value is 12. Take it out and wash it until neutral, soak it in an acetic acid solution with a pH value of 4.5 for 30 minutes, and wash it with water until neutral.

[0028] (2) Dyeing process route and prescription

[0029] Kehuasu Yuanqing B133% or Kehuasu Navy GG or Kehu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com