Composite cruising ballast water treatment process

A technology for ship ballast water and treatment methods, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as bulky equipment, difficult installation, and increased chemical substances , to achieve the effect of simple design process route, reliable working principle, and solution to the spread of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

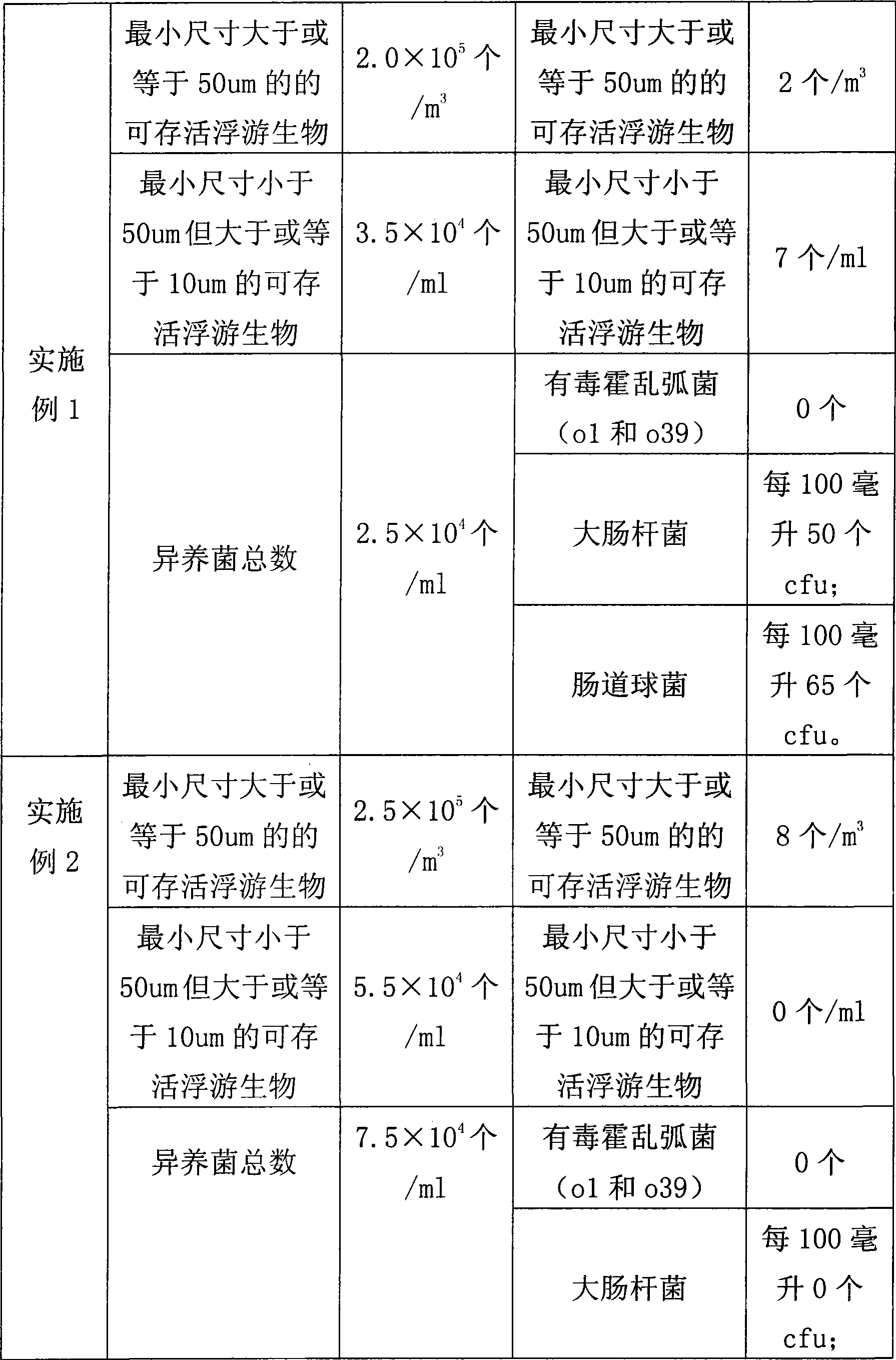

Embodiment 1

[0012] Embodiment 1: First adopt the automatic backwashing filter that filter precision is 30um to filter, then use the 5ppm sodium hypochlorite that electrolysis produces to carry out inactivation.

Embodiment 2

[0013] Embodiment 2: First adopt the automatic backwashing filter that filter precision is 40um to filter, then use the 10ppm sodium hypochlorite that electrolysis produces to carry out inactivation.

Embodiment 3

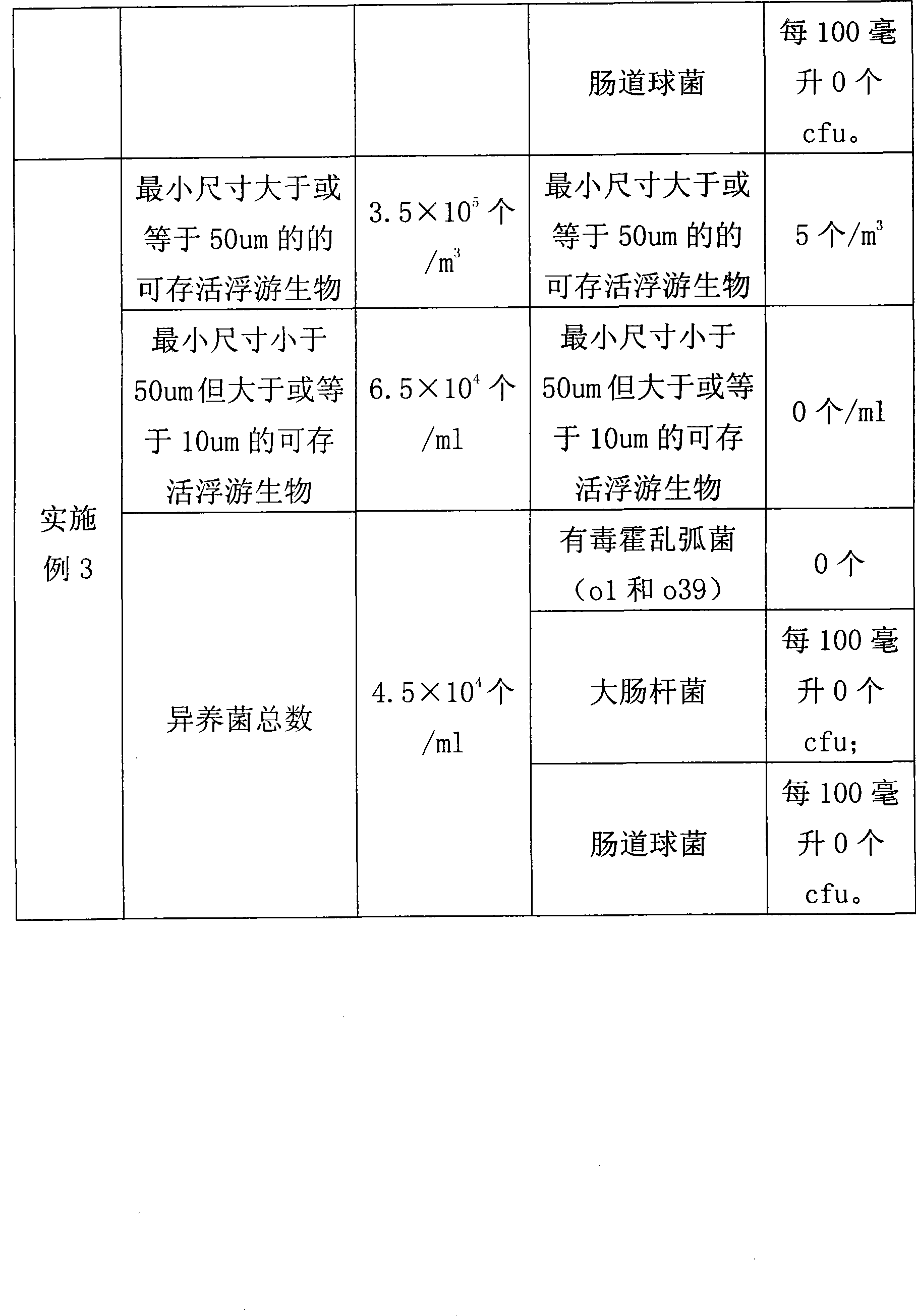

[0014] Embodiment 3: First adopt the automatic backwashing filter that filter precision is 35um to filter, then use 7.5ppm sodium hypochlorite produced by electrolysis to inactivate.

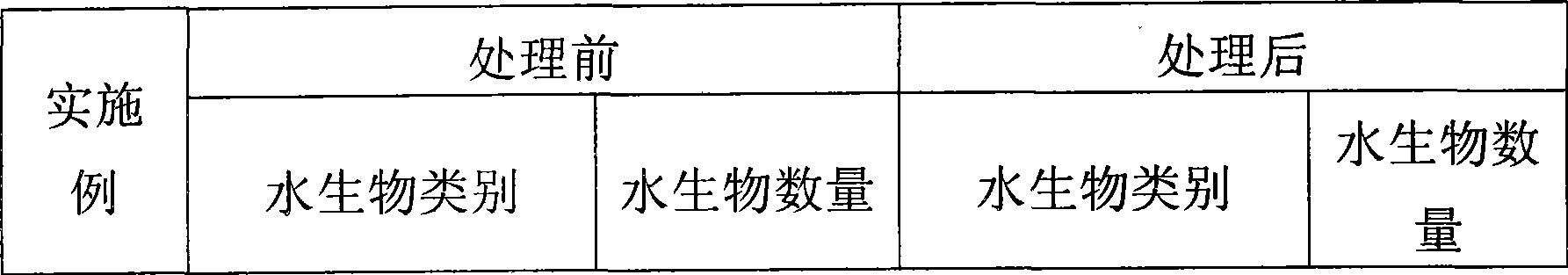

[0015] Table 1 Comparison of ballast water treatment effects of three examples

[0016]

[0017]

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com