Process for treating hydrazine hydrate waste salt water by ketone linking nitrogen method

A technology of ketazine method and treatment method, which is applied in the field of by-product waste brine treatment, can solve the problems of unfavorable environment, consumption of raw materials, environmental pollution, etc., and achieve the effect of fully utilizing resources and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

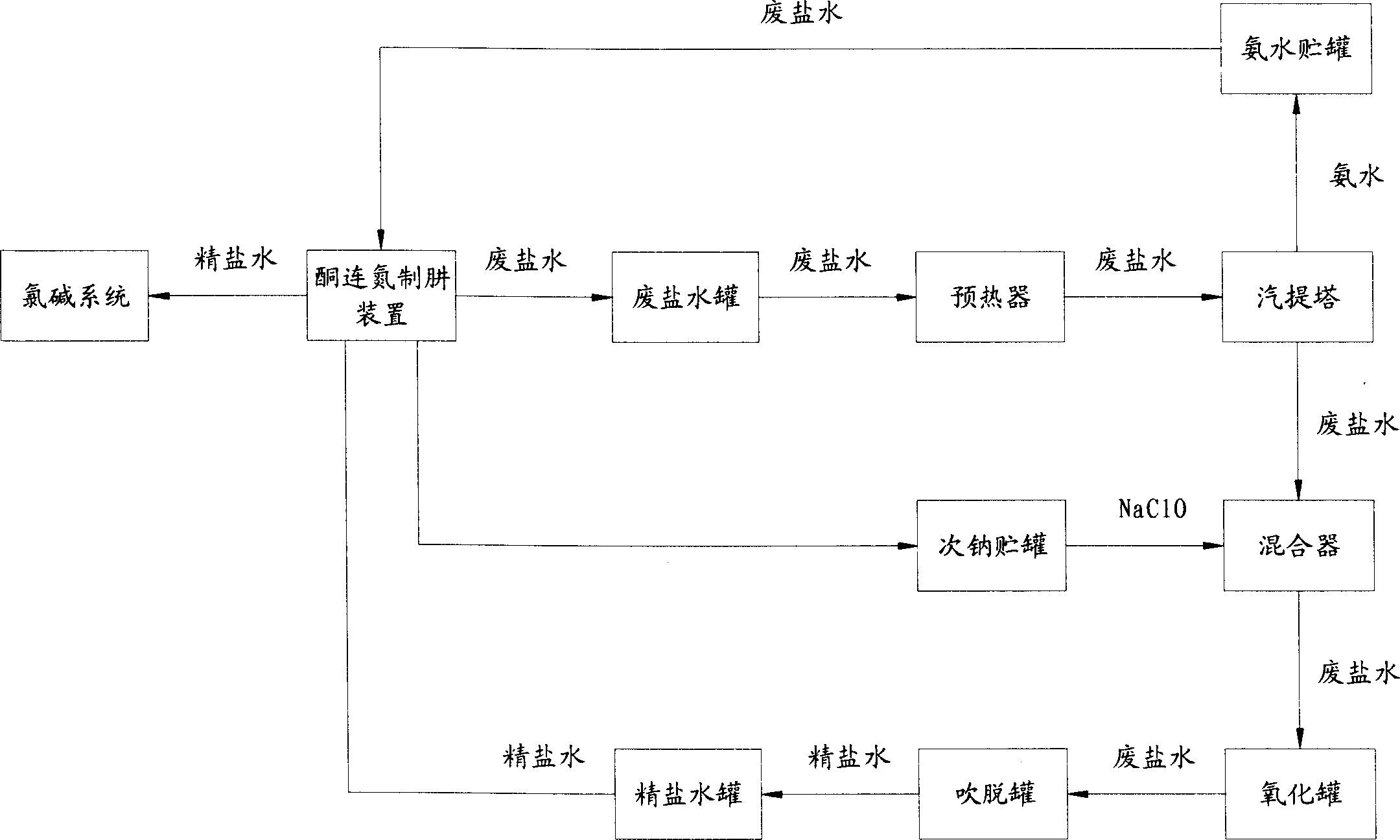

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described, but the present invention is not limited to these examples:

[0026] The chemical substances and their content ranges contained in the waste brine in the production process of ketazine method hydrazine hydrate are as follows:

[0027] Sodium hydroxide: 0.15%, ammonia: less than 0.1%, hydrazine hydrate: less than 0.1%, acetone: less than 0.1%, isopropylhydrazine and isopropanol are produced by side reactions, and their content depends on the specific conditions of production. The difference can reach about 2%. The following embodiments are based on the premise of normal working conditions.

[0028] Preheat the waste brine in the above-mentioned ketazine method hydrazine hydrate production process to 85°C-90°C through the preheater, and then control about 20m through the flow meter 3 The flow rate per hour continuously enters a rectification device. This rectif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com