Energy saving and consumption reduction method of aluminum reduction cell

An aluminum electrolytic cell and electrolytic cell technology, applied in the field of aluminum electrolysis, can solve the problems of high electrolyte voltage, high power consumption of the electrolytic cell, unstable electrolytic cell, etc., and achieve the effects of reducing the pole distance, improving the utilization rate of electric energy, and reducing fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

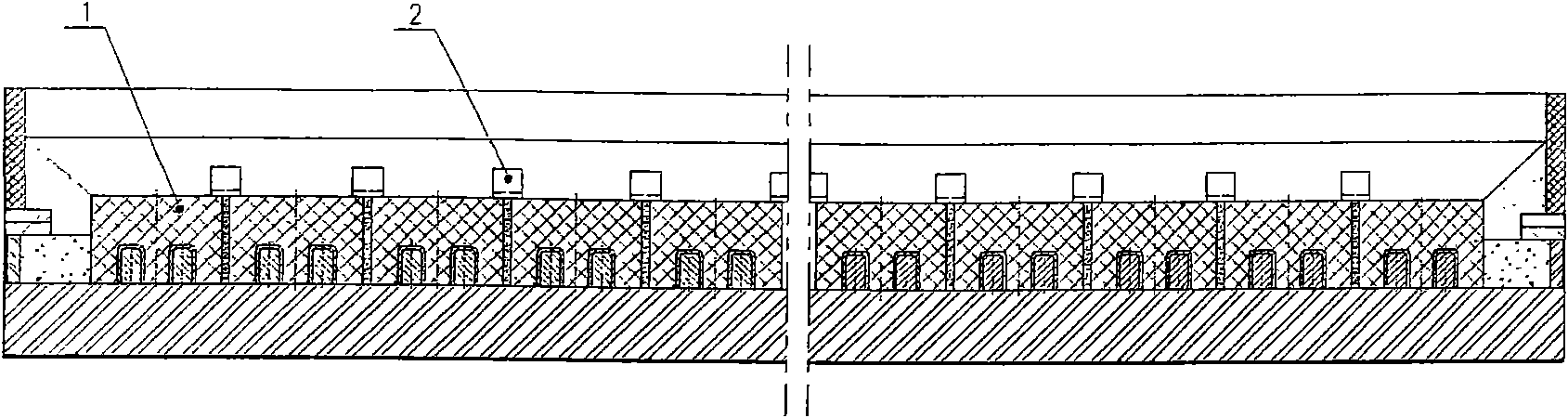

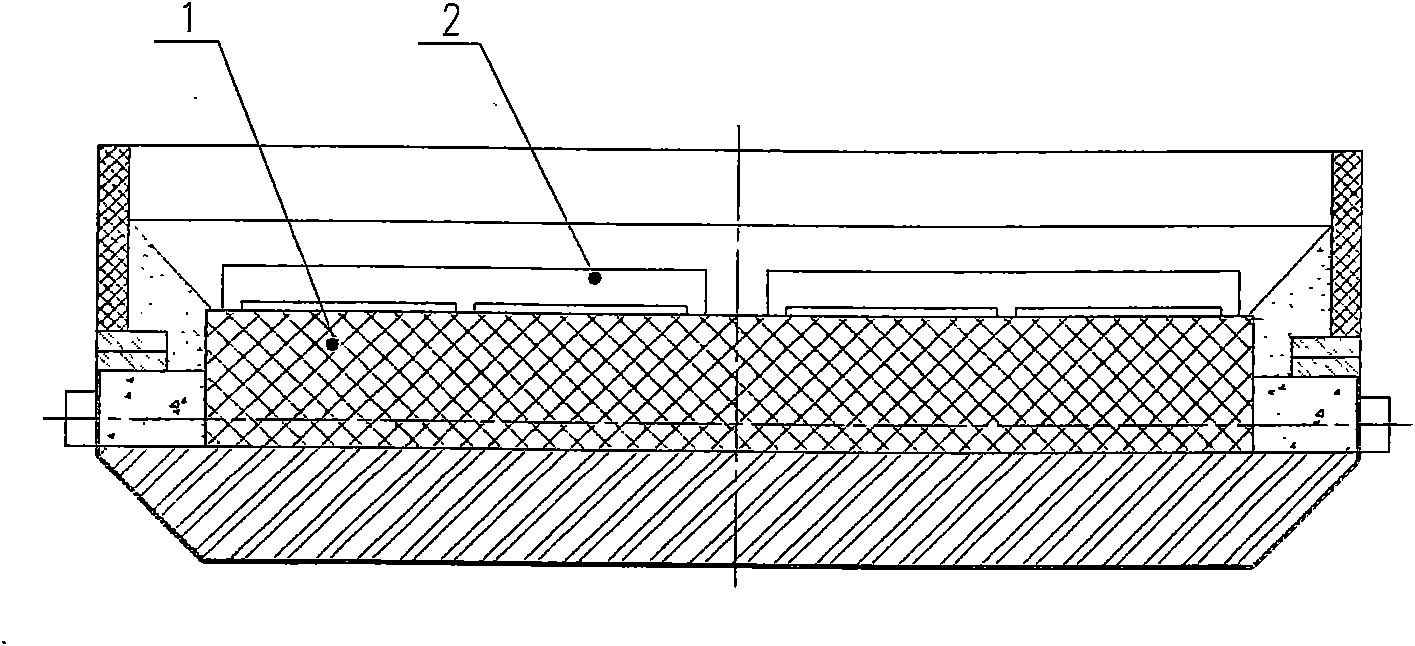

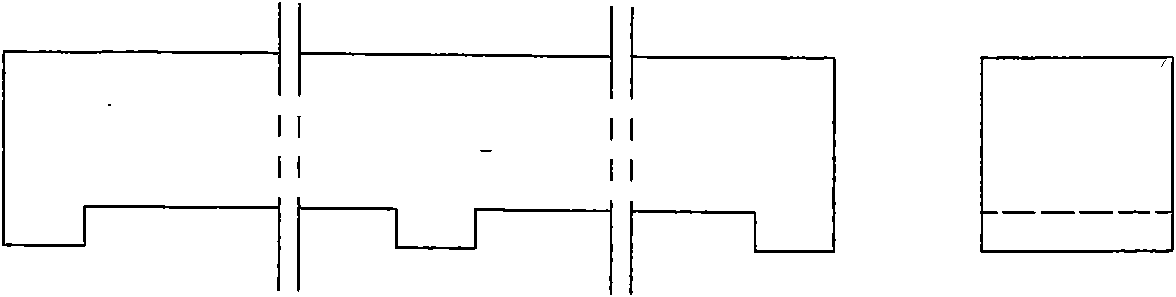

[0025] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

[0026] like Figures 1 to 3 As shown, the method for saving energy and reducing consumption of the aluminum electrolytic cell of the present invention is to place several stoppers 2 on the aluminum liquid layer on the upper surface of the cathode carbon block 1 . More specifically, the block 2 is placed horizontally on the aluminum liquid layer on the upper surface of the cathode carbon block 1 along the long axis or short axis of the electrolytic cell.

[0027] The density of the block 2 is greater than that of the molten aluminum. The height of the stopper 2 is less than or equal to the height of the aluminum liquid layer. The width of the block 2 is smaller than that of the cathode carbon block. The length of the stopper 2 is less than or equal to the size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com