Cathode of aluminum cell

An aluminum electrolytic cell and electrolytic cell technology, applied in the field of aluminum electrolytic cells, can solve problems such as increased energy consumption and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

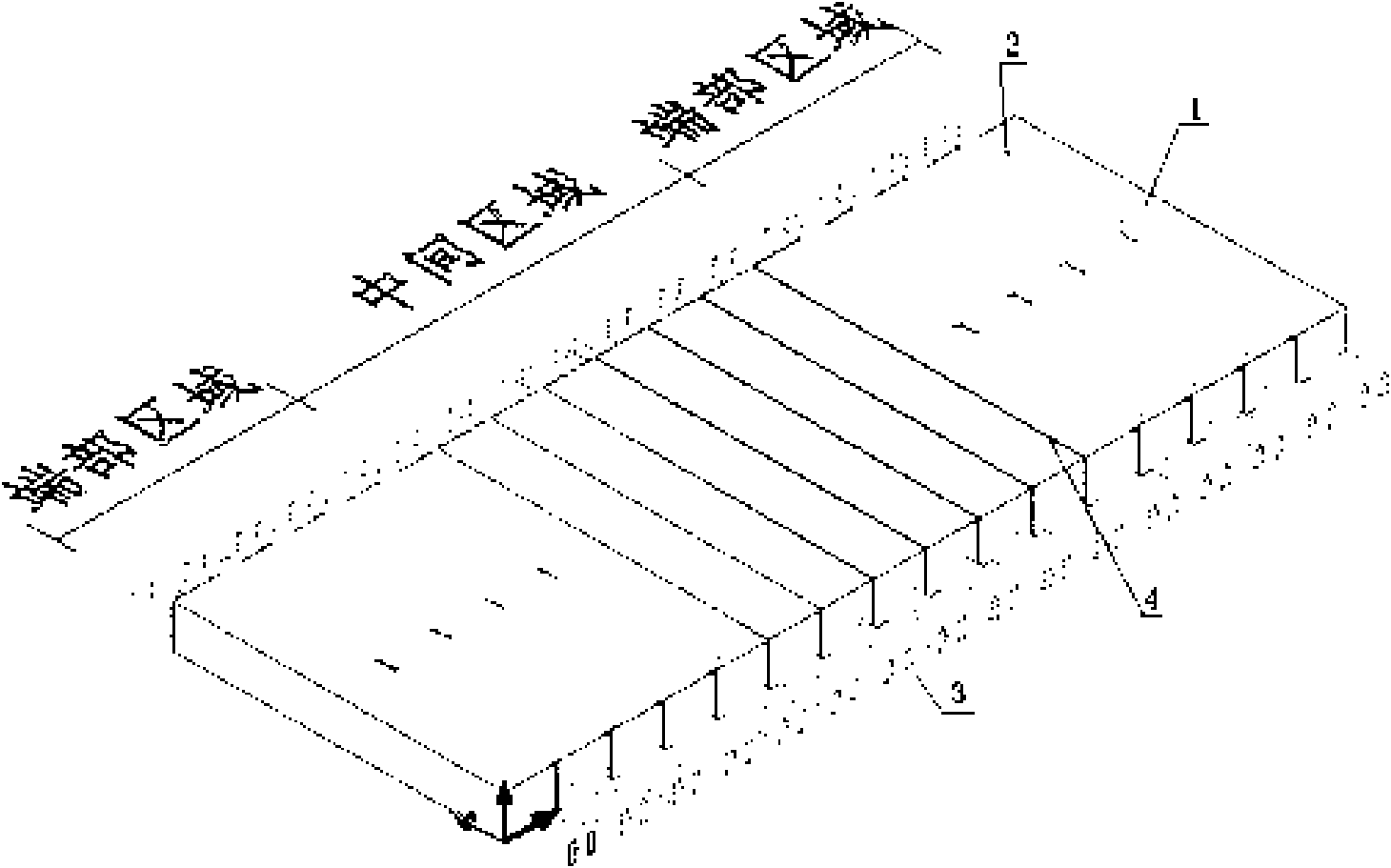

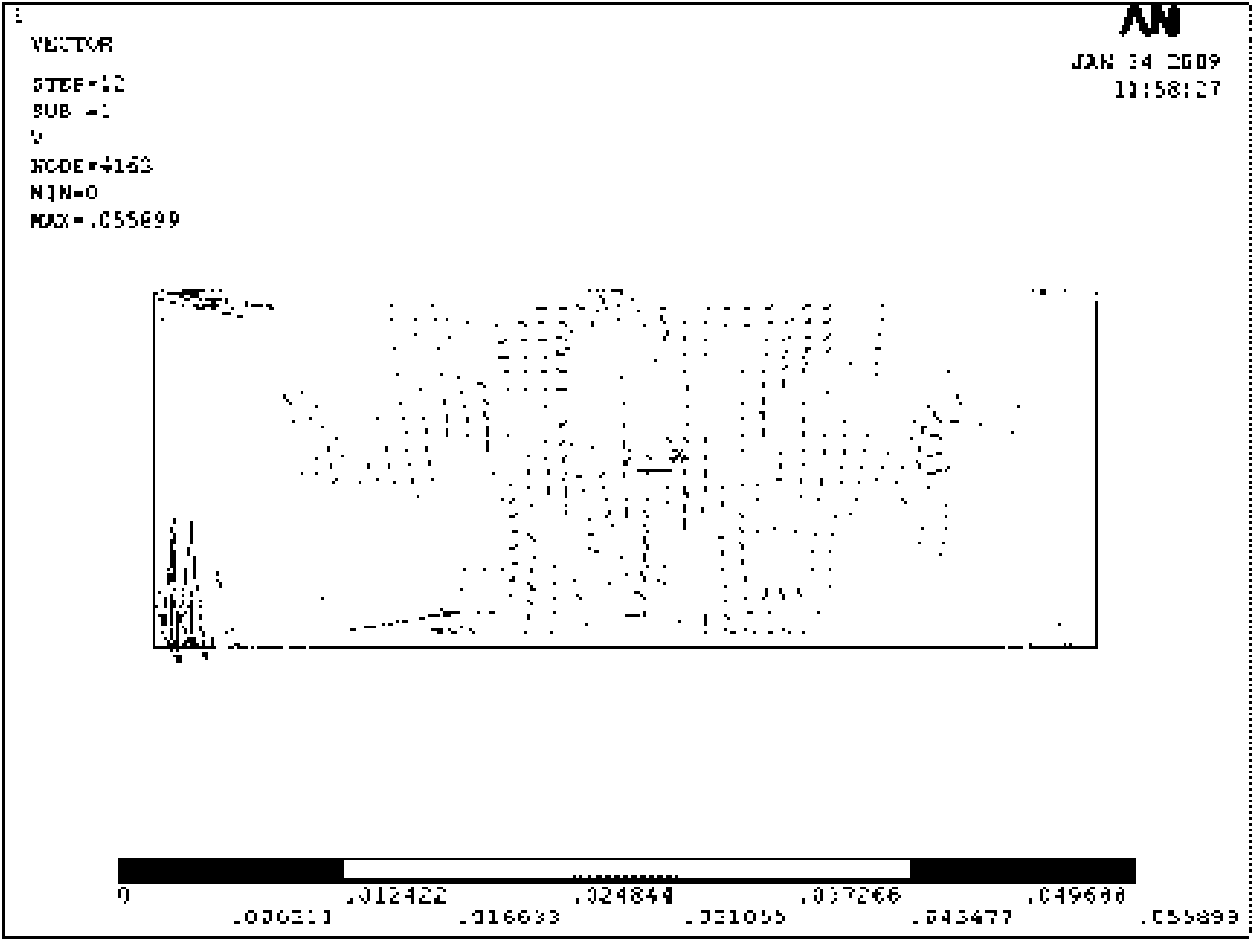

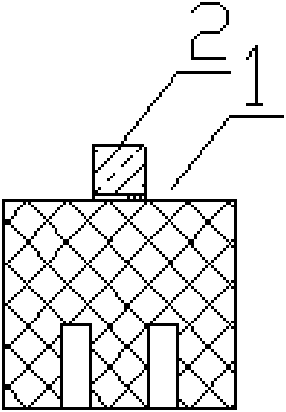

[0031] Example: such as figure 1 As shown, the cathode carbon block 1 is arranged at the bottom of the aluminum electrolytic cell, and the two ends of the cathode carbon block are provided with cathode steel rods 3, and the cathode carbon blocks 1 are spliced by pasting 4; The surface of the cathode carbon block 1 is provided with a protruding strip 2, the height of the protruding strip 2 is 50-200mm, the protruding strip 2 is arranged along the longitudinal direction of the cathode carbon block 2 (series current direction), and the protruding strip 2 can be arranged on the top of the cathode carbon block 1 the middle of the surface (such as image 3 ), edges (such as Figure 4 ), or on the seam where two cathode carbon blocks 1 are spliced (such as Figure 5 ), the protruding strip (2) can be pasted by binding (such as Image 6 ), bonding (such as Figure 7 ), mosaic (such as Figure 8 ) or integrally cast on the surface of the cathode carbon block 1. At the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com