Positioning force complementary double-stator cylindrical linear motor

A linear motor, complementary technology, applied in the direction of electrical components, electromechanical devices, medical science, etc., can solve the problems that cannot be controlled independently, low power density, increase the length of the motor, etc., achieve high winding utilization, reduce quantity, and save energy The effect of axial space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

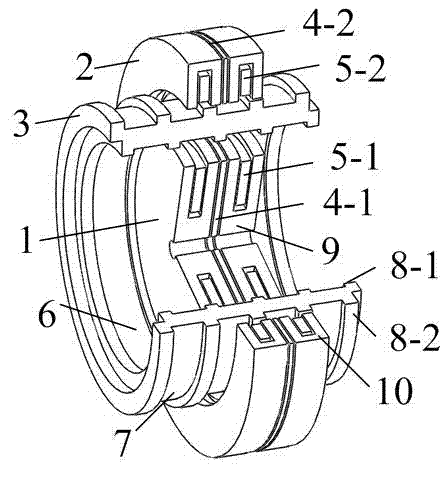

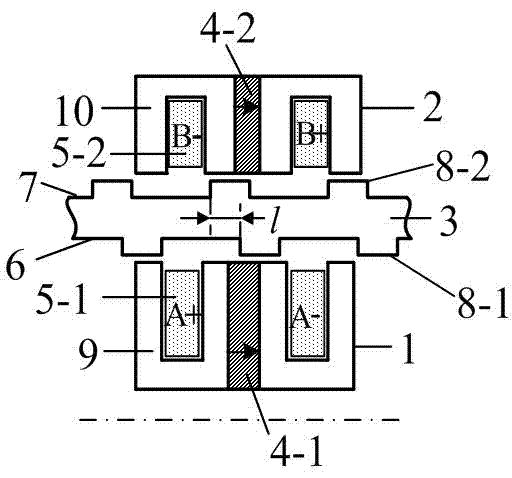

[0021] like figure 1 and figure 2 As shown, the present invention is composed of an inner stator ring 1, an outer stator ring 2, and a mover ring 3. The inner stator ring 1, the outer stator ring 2, and the mover ring 3 are coaxial, and the axial direction is also the direction in which the mover moves. . The mover ring 3 is emptied outside the inner stator ring 1 , and the outer stator ring 2 is emptied outside the mover ring 3 , that is, the mover ring 3 is placed between the inner stator ring 1 and the outer stator ring 2 .

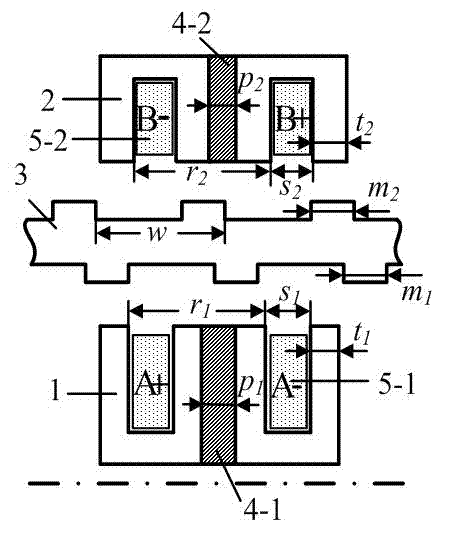

[0022] The inner fixed ring 1 is composed of the first permanent magnet 4-1 and two inner annular U-shaped teeth 9 with the same structure. The teeth 9 are processed from magnetically permeable materials, the first permanent magnet 4-1 is sandwiched between two inner annular U-shaped teeth 9, and the first permanent magnet 4-1 is excited along the axial direction. A set of annular first armature windings 5-1 is embedded in the two U-shaped grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com