Transverse magnetic flux magnetic field modulation type linear motor

A linear motor and magnetic field modulation technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as the reduction of fault tolerance performance, and achieve the effects of improved space utilization, simple adjustment, and improved harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

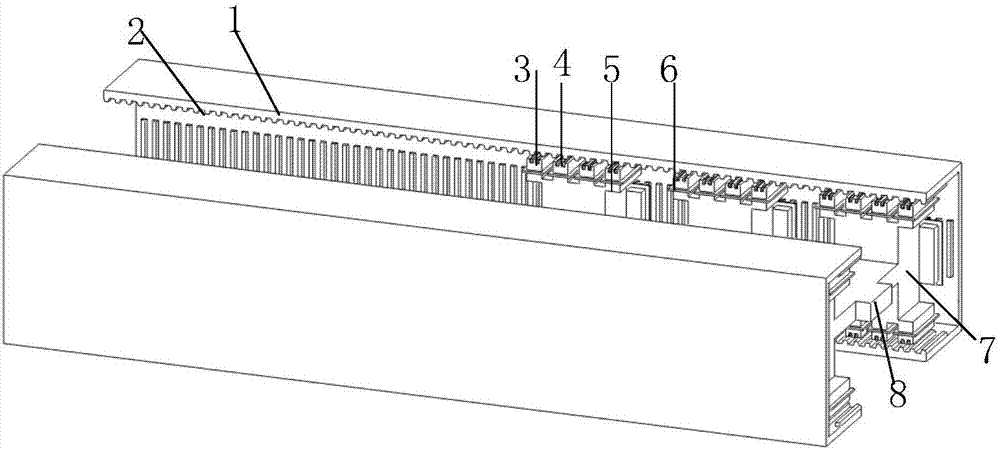

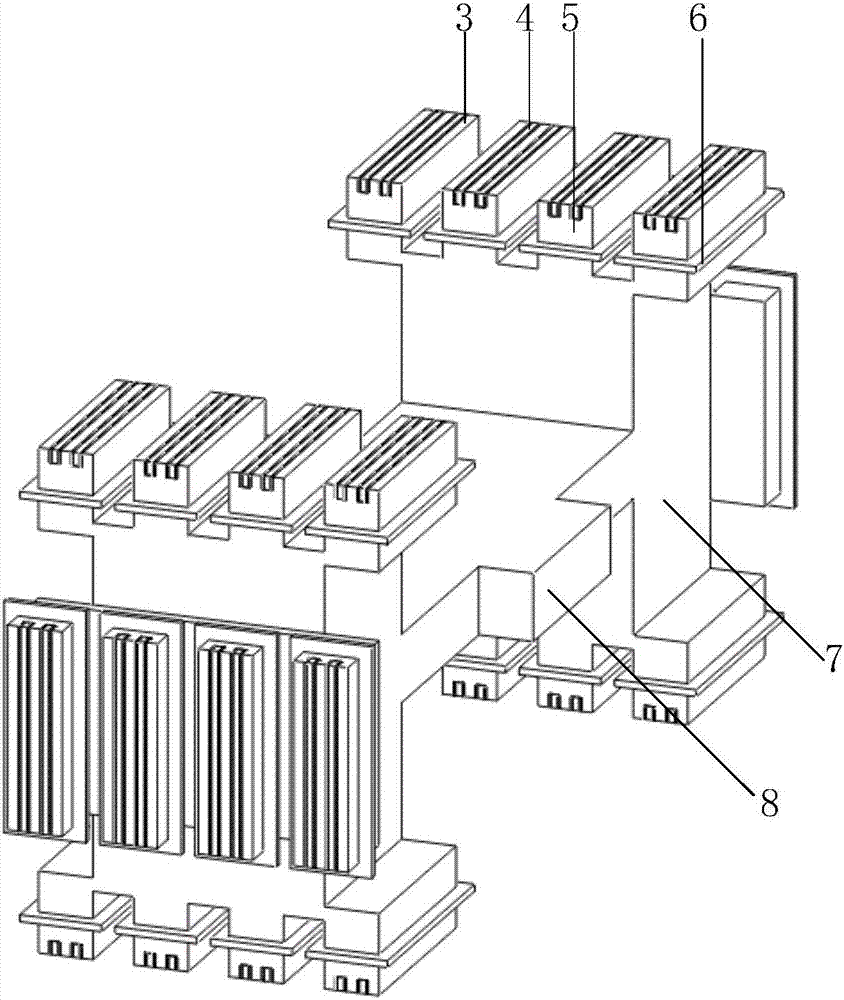

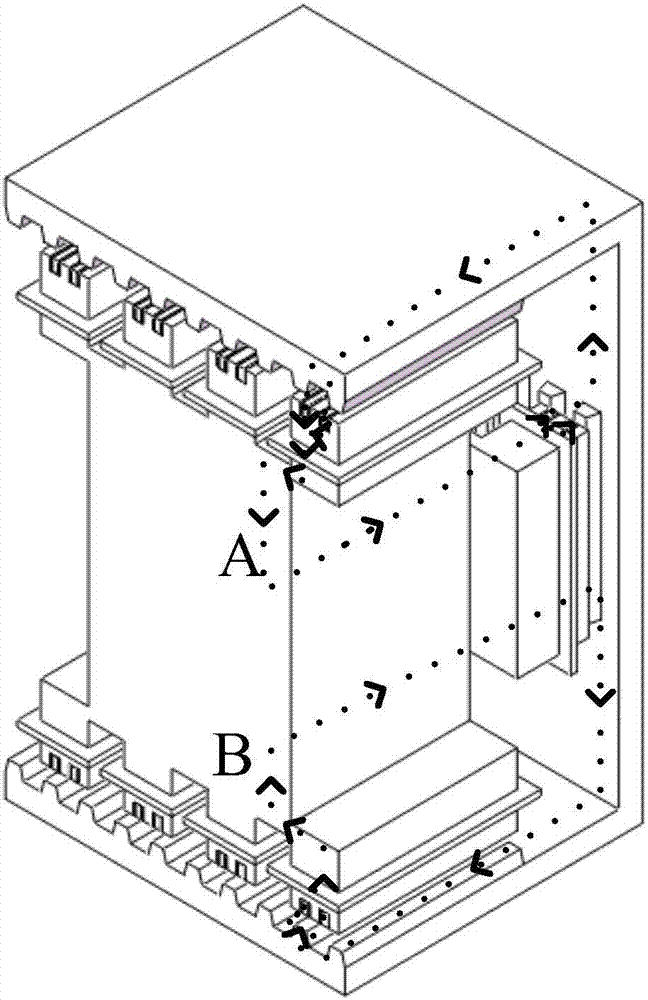

[0023] Please refer to figure 1 As shown, it is a structural schematic diagram of the transverse flux magnetic field modulation linear motor of the present invention, and the transverse flux magnetic field modulation linear motor includes: primary and secondary; the present invention combines magnetic field modulation on the basis of transverse flux A transverse flux magnetic field modulation type linear motor is proposed. The two secondary stages are made of silicon steel sheets, which are in the shape of a "C" and mirrored. There is no permanent magnet attached to the pivot winding, only simple secondary slots 1 and secondary teeth 2 are equidistantly distributed, and there are three-sided air gaps between the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com