Disc type motor rotor with pole shoe composite magnetic pole structure

A disc motor and magnetic pole structure technology, applied in the field of electric motors, can solve the problems of poor magnetic field weakening ability of the motor, decreased motor performance, permanent magnet heating, etc., to reduce the torque fluctuation index, improve the sine degree, and reduce the harmonic content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

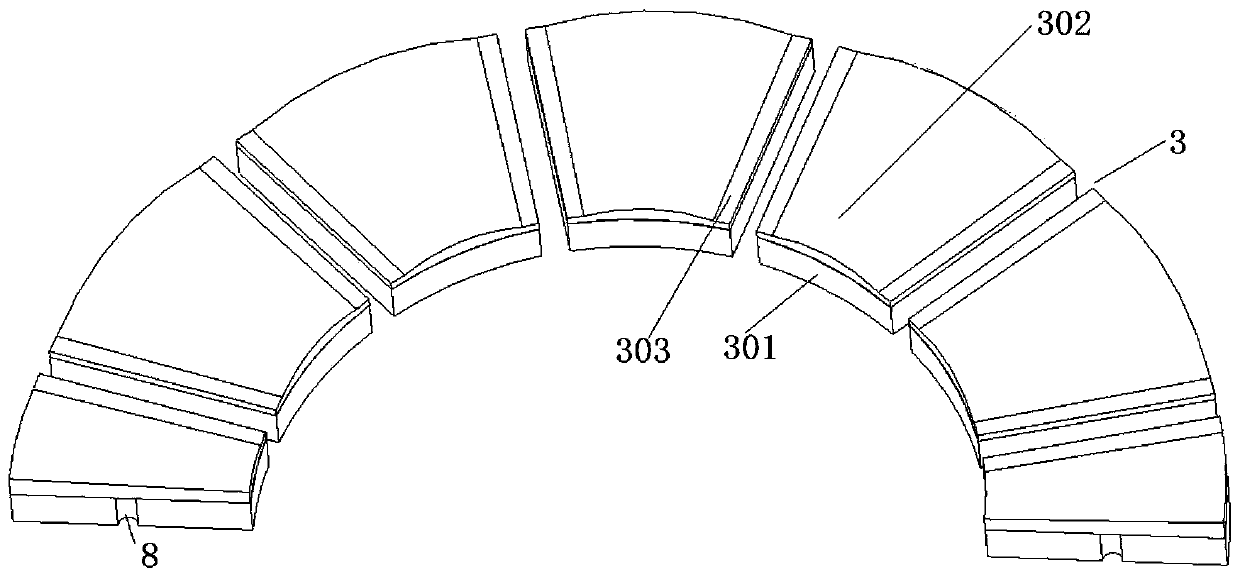

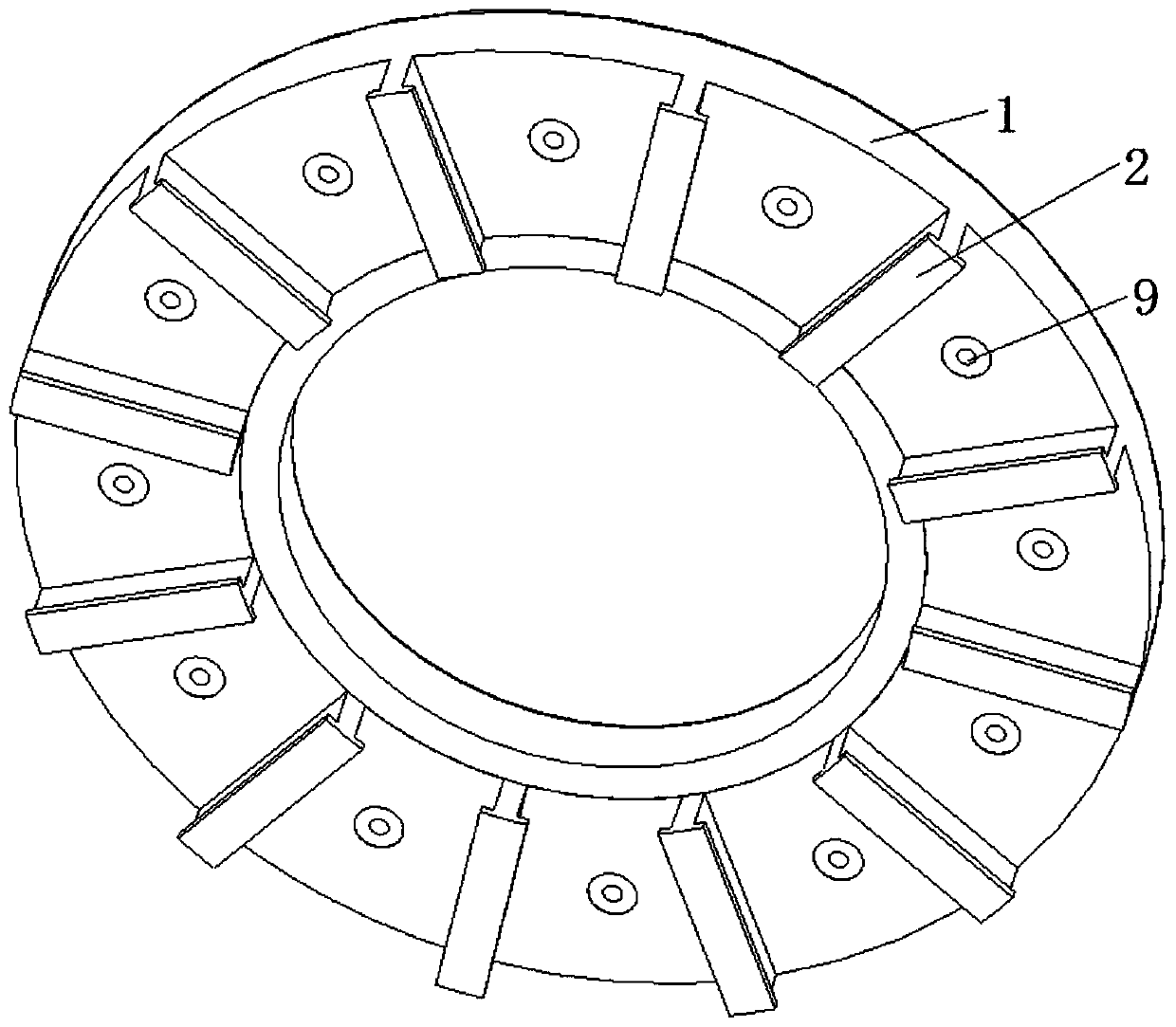

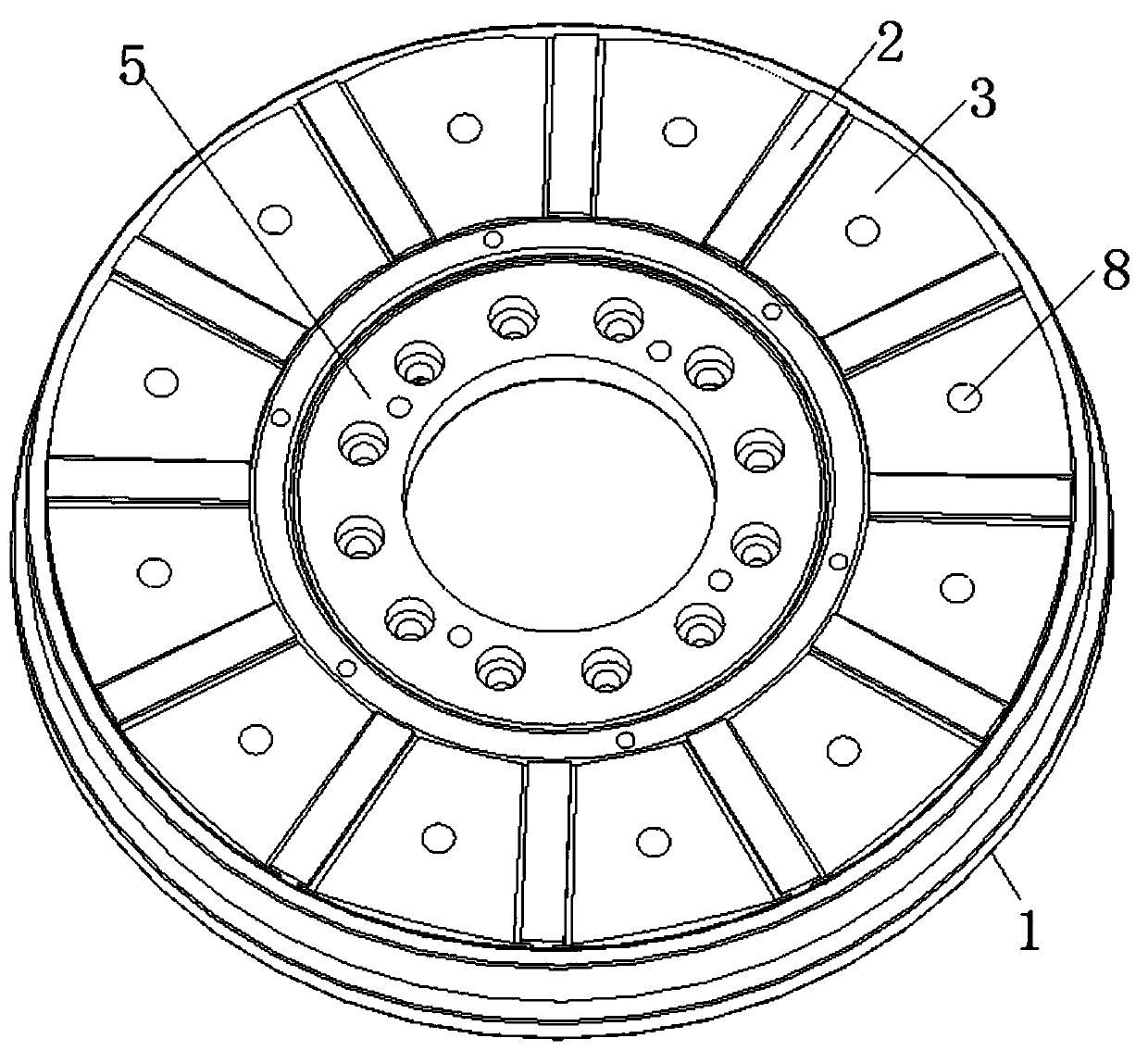

[0029] The present invention provides a disc motor rotor with a pole shoe composite magnetic pole structure, such as Figure 1-Figure 4 As shown, the rotor core 1 including the annular structure can be formed by winding a silicon steel strip. The rotor core 1 is provided with a plurality of T-shaped baffles 2, and the T-shaped baffles 2 divide the rotor core 1 into multiple parts along the circumference. A fan-shaped space; a pole shoe compound magnetic pole 3 is inserted radially into the fan-shaped space between two T-shaped baffles 2. The rotor support plate 4 is set in the shape of a disc with a hole in the center, and the upper surface is set as a groove with a pot-shaped structure. The outer surface of the groove restricts the radial outward movement of the rotor core assembly, and a fixed ring is arranged near the inner wall of the basin-shaped junction groove, and the radial inward movement of the rotor core assembly is restricted by the fixed ring 5; Holes are drille...

Embodiment 2

[0034] Such as Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, in another embodiment, the rotor support plate 4 is made of non-magnetic aluminum alloy material, the rotor core in the first embodiment is omitted, and the permanent magnets with pole shoes and composite magnetic poles 3 are provided with structures on both sides. The same pole shoe 302, that is, the double-sided pole shoe structure, the rotor support plate 4 and the annular baffle 11 are arranged symmetrically in cross-section, and the fastening structure of the screw or rivet can effectively fix the composite magnetic pole 3 of the pole shoe, with a magnetically conductive material pole The rotor structure of the shoe makes the inductance of the AC and DC axes of the motor different, which improves the magnetic field weakening capability of the motor. The pole shoe isolates the eddy current effect of the high-frequency harmonic magnetic field on the permanent magnet, and prevents the eddy current hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com