Modular axial flux permanent magnet motor

A technology of axial flux and permanent magnet motors, applied in the direction of magnetic circuits, electric components, electromechanical devices, etc., can solve the problems of reduced motor efficiency, poor structural strength, and reduced mechanical strength of the stator, and achieve improved torque/power density , Improve the mechanical strength, improve the effect of heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

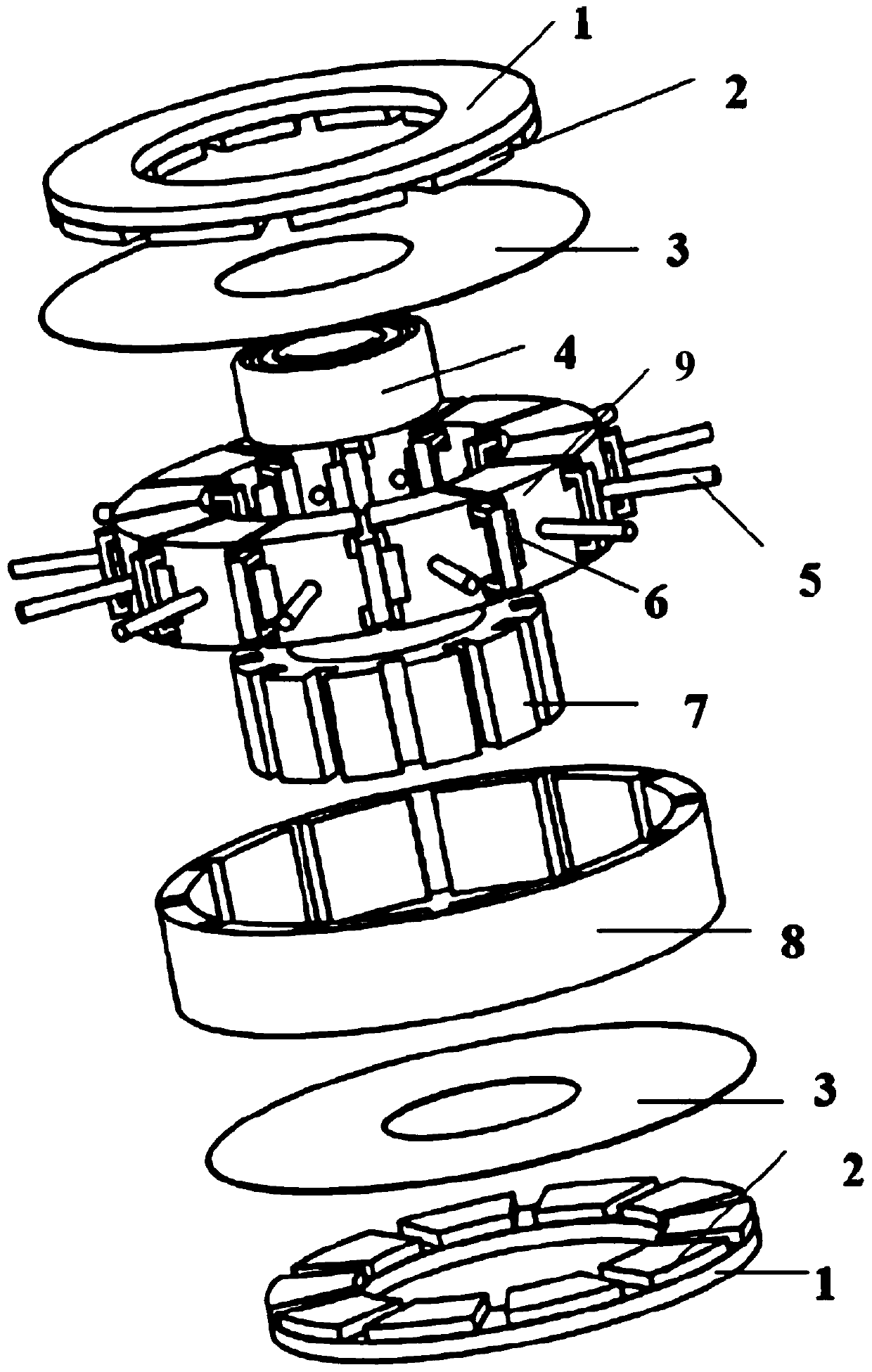

[0041] combine figure 1 , the modular axial flux permanent magnet motor of the present invention has a concentrated winding structure of 9 slots and 8 poles, including a stator, a double rotor and a bearing 4;

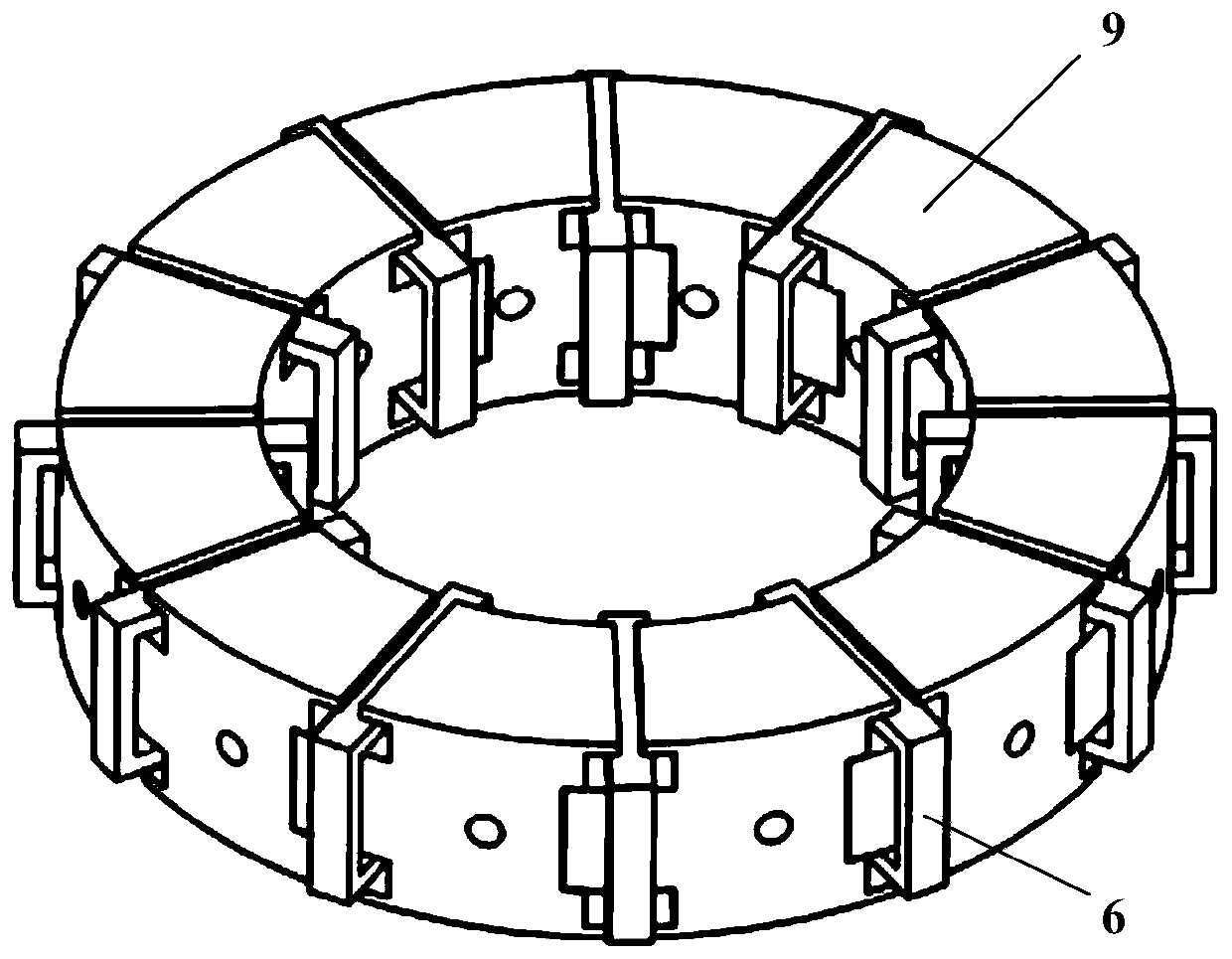

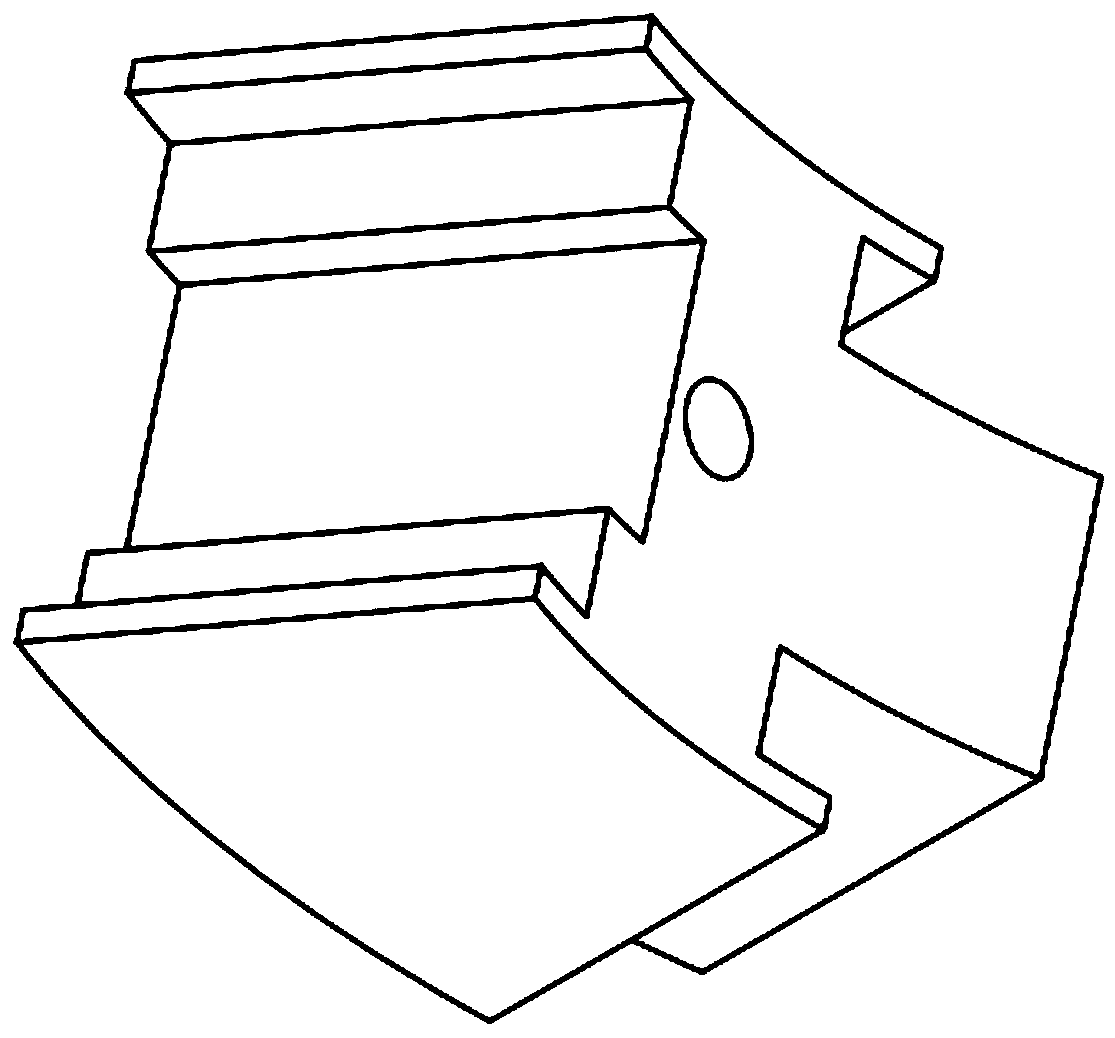

[0042] The stator includes a stator core 9, a stator winding 6, a stator core fixing pin 5 and a stator sealing plate 3, and the overall structure of the stator core 9 is as follows figure 2 As shown, the entire stator core 9 rings include N stator modules, where N is a positive integer divisible by 3. In this embodiment, N=9. The structure of each stator module is as follows image 3 As shown in , first wind each stator winding 6 on a single stator module, and then connect N stator modules end to end to form a closed ring, as shown in figure 2 shown.

[0043] Since the stator is placed in the middle of the double rotors, when the motor is running at high speed, when the rotor is dynamically eccentric or statically eccentric, the air gaps on both sides will be asym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com