Cylindrical magnetic-pole combined linear generator

A linear generator and magnetic pole technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of large jitter, high harmonic content of motors, and low output power quality, and achieve small jitter, high energy conversion rate, and increased stability and the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

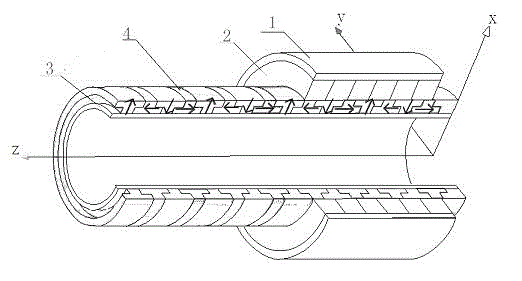

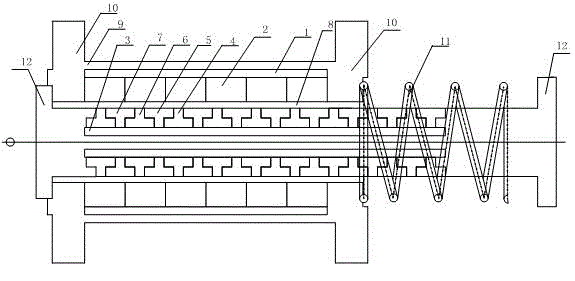

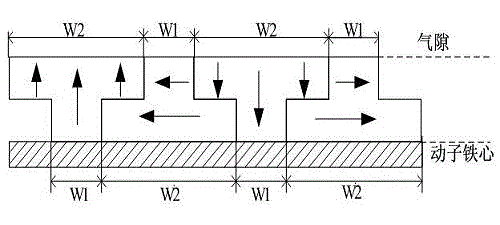

[0025] Such as Figure 1-2 As shown, the present invention provides a cylindrical magnetic pole combination non-cogging linear generator. The permanent magnet generator mainly includes a stator core 1, a concentrated cake-type stator winding 2; a mover core 3, and a magnetization direction of 90°, etc. Poor T-shaped permanent magnet rings 4 are staggeredly installed on the mover iron core shaft. The permanent magnet rings are made of NdFeB permanent magnet materials. The stator core is made of silicon steel sheets. Alloy.

[0026] There is an air gap 8 between the stator structure and the mover structure, and a sealing ring 9 and a stator end cover 10 are arranged outside the stator core structure. The stator end cover is made of non-magnetic material and its outer diameter is larger than that of the stator core, which is convenient for fixing motor. A compression spring device 11 is installed between the stator end cover and the mover end cover 12 .

[0027] Fix the non-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com