Outer surface structure of magnetic steel embedded rotor

An embedded, external surface technology, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problem of large Q-axis magnetic circuit reluctance, weak motor reluctance torque component, and quadrature-axis inductance. Small and other problems, to achieve the effect of reducing reluctance, multi-reluctance torque components, and weakening negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

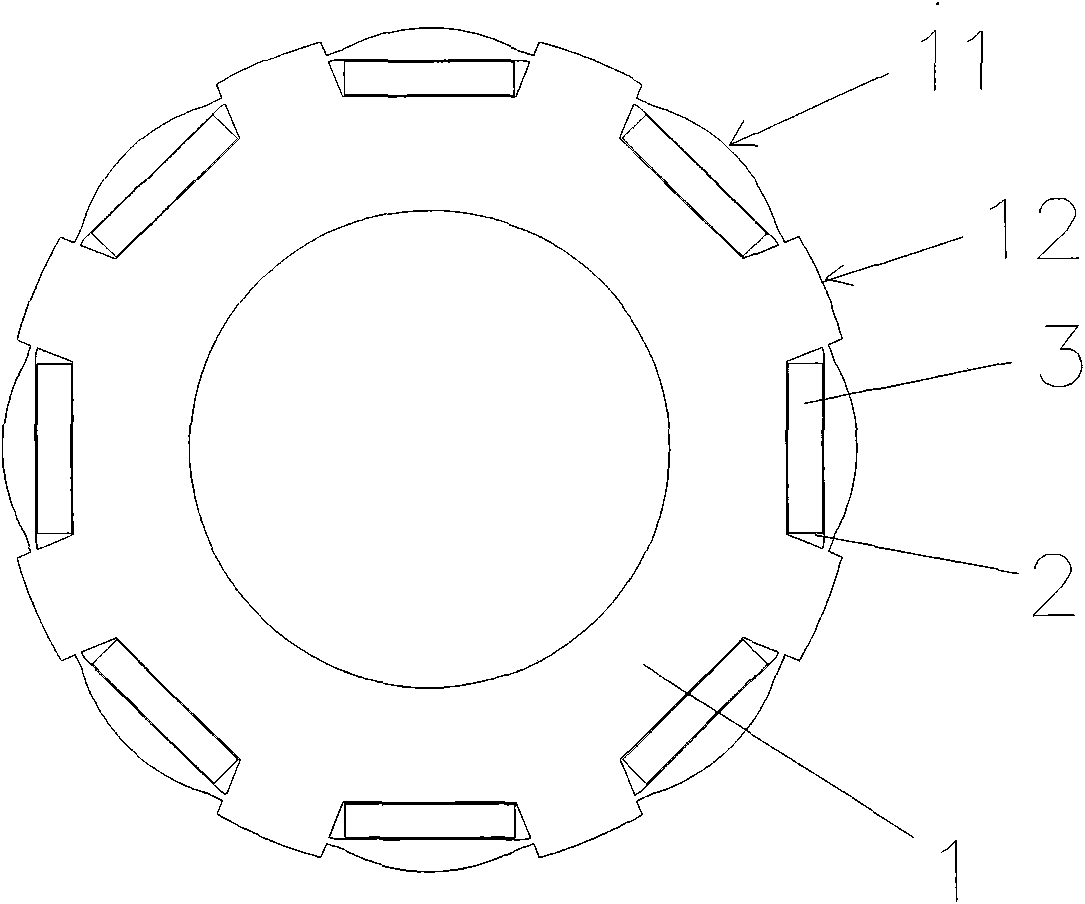

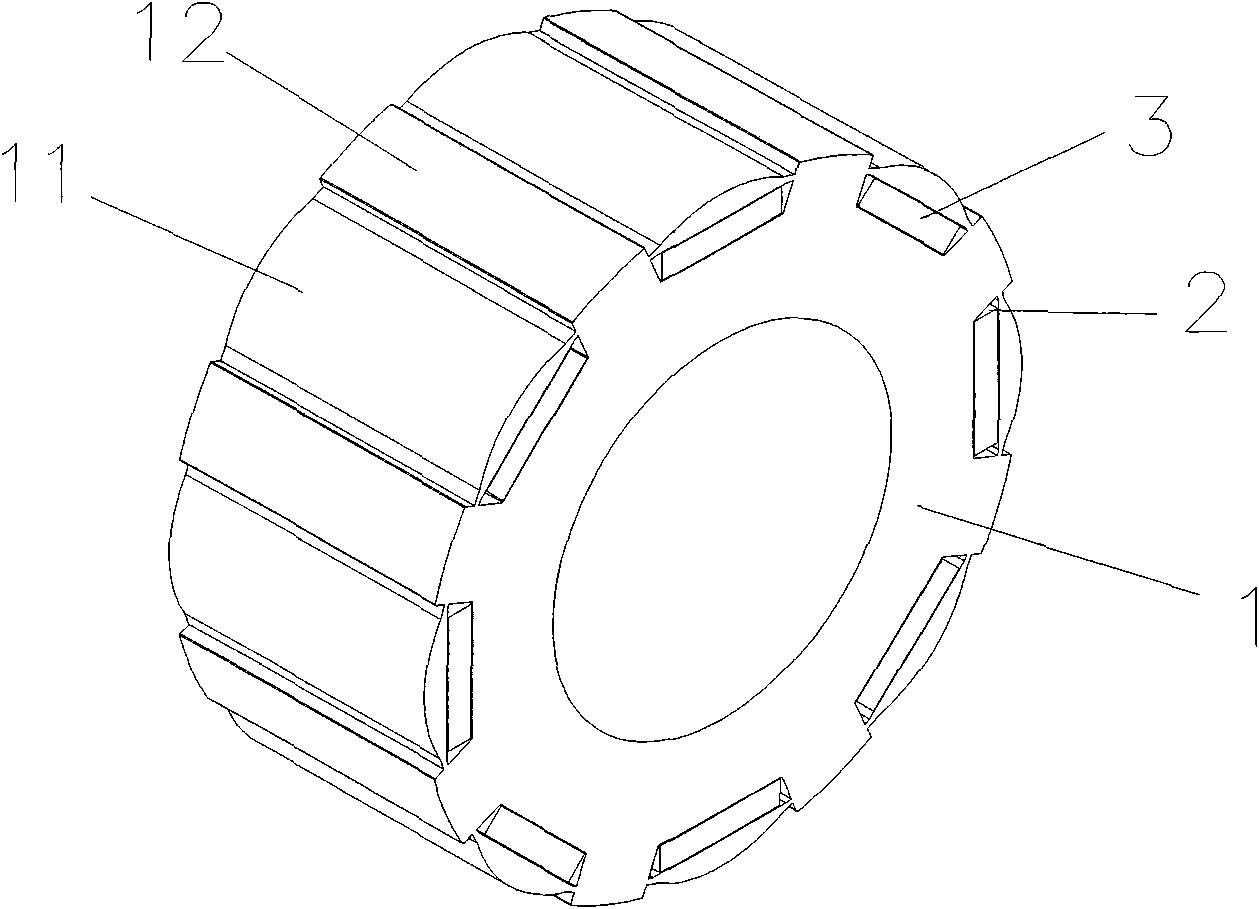

[0010] see figure 2 , image 3 , the magnetic steel embedded rotor involved in the present invention includes a rotor core 1, an even number of axially penetrating magnetic steel grooves 2 are evenly distributed on the rotor core 1, and a plurality of magnetic steels 3 are embedded in the N pole and S pole interval. In each magnetic steel slot, the outer surface of the rotor core is an arc-shaped surface 11 of a sinusoidal air gap at the part corresponding to each magnetic steel slot, and a circle with a uniform air gap at the part corresponding to two adjacent magnetic steel slots. Shaped surface 12.

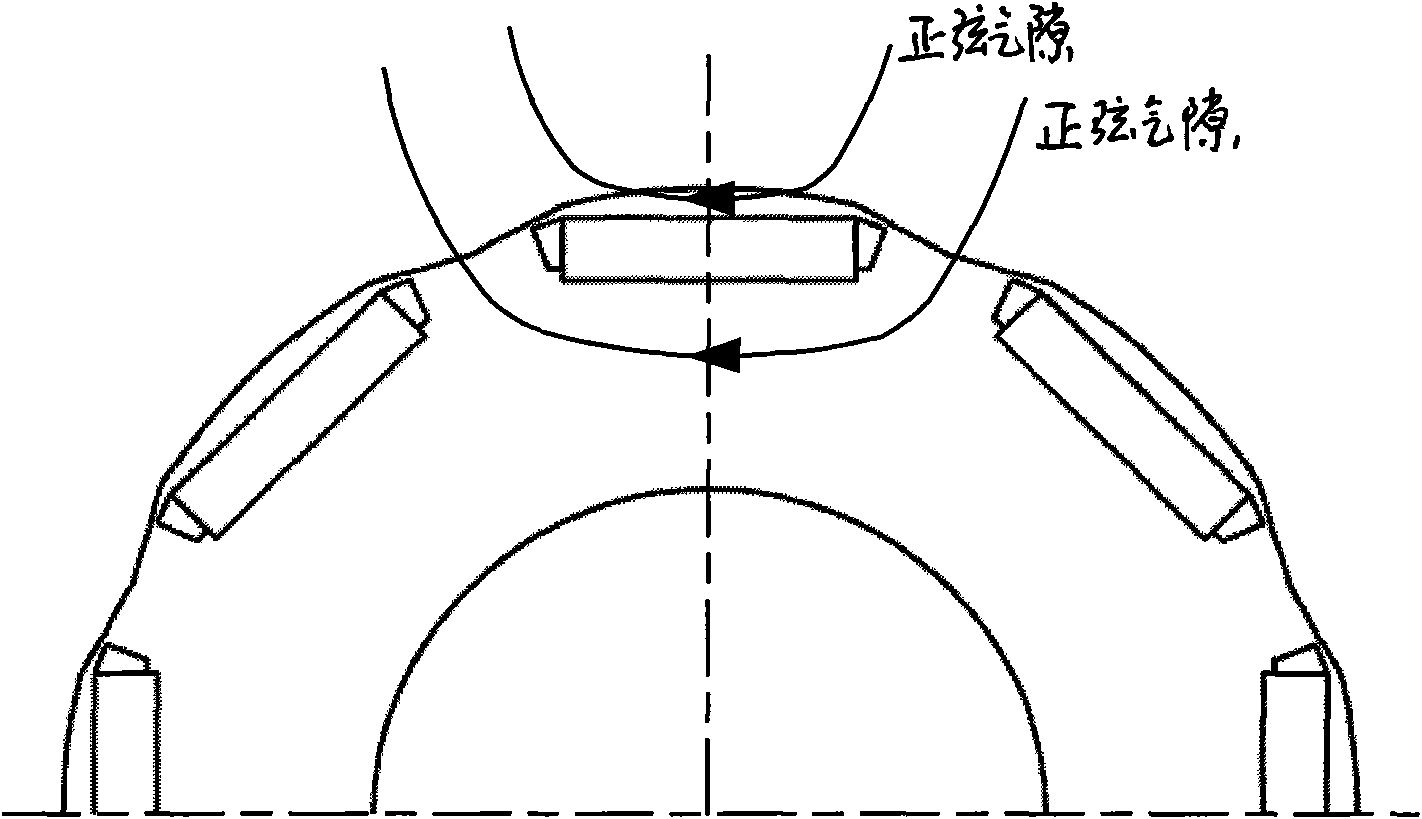

[0011] The Q-axis magnetic circuit of the magnetic steel embedded rotor of the present invention is as follows: Figure 4 shown. While retaining part of the sinusoidal air gap, it changes the Q-axis magnetic circuit of the motor into a uniform air gap, which effectively reduces the reluctance of the Q-axis magnetic circuit. Therefore, compared with the traditional simple si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com