Built-in permanent magnet motor rotor magnetic field improved design method suitable for industrialization

A permanent magnet motor and rotor magnetic field technology, which is applied in the manufacture of motor generators, stator/rotor bodies, magnetic circuits, etc., can solve the problems of difficult manufacturing of rotor stamping dies, high processing accuracy and high production costs, and reduce positioning torque , Simplify the manufacturing process and reduce the effect of cogging torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

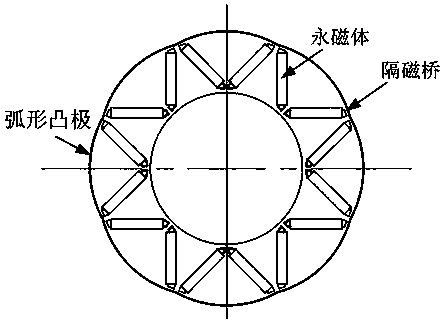

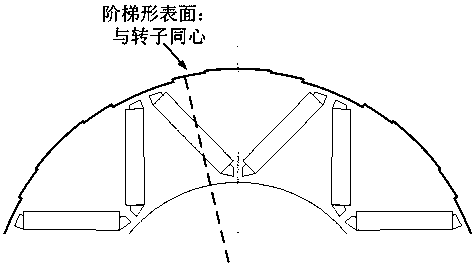

[0033] Such as image 3 As shown, the built-in permanent magnet motor designed in this embodiment has a stator outer diameter of 190 mm, a rotor outer diameter of 110 mm, an axial length of 100 mm, and an air gap length of 2 mm. The rotor has 8 magnetic poles and is designed with 2-section V-shaped magnetic steel.

[0034] When the rotor is designed with a cylindrical punch, the air gap magnetic density amplitude is 0.69 T, the waveform is flat-top wave, the fundamental wave amplitude is 0.85 T, the phase potential amplitude is 97.5 V, and the positioning torque is 102 mNm.

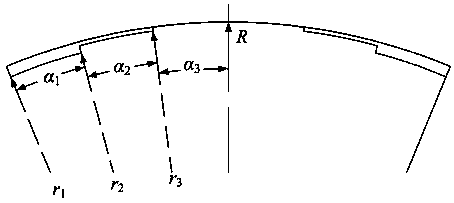

[0035] When the rotor adopts a three-stage stepped arc-shaped punch design, the air gap magnetic density amplitude is 0.73 T, the waveform is an approximate sine wave, and the fundamental wave amplitude is 0.84 T. The phase potential amplitude is 110.5 V, which is 13.3% higher than that of the cylindrical punch. The positioning torque is 14.2 mNm, which is 86.1% lower than the cylindrical punching. The cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com