Square-wave rotor based on permanent magnet and inner rotor core eccentric structure design

An eccentric structure and permanent magnet technology, applied in the direction of magnetic circuits, electromechanical devices, electrical components, etc., to achieve the effects of preventing magnetic flux leakage between poles, improving back electromotive force waveforms, and reasonable length changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

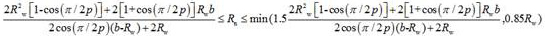

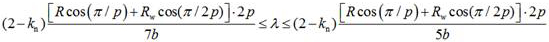

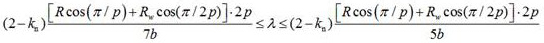

[0035] Embodiment 1 discloses a square-wave rotor designed based on a permanent magnet and an eccentric structure of an inner rotor core used in a brushless DC energy storage flywheel generator. Reference attached figure 1 And attached figure 2 , which includes an outer rotor core 1 , an eccentric permanent magnet 2 , an inner rotor core 3 and a rotor shaft 4 . Both the outer rotor core 1 and the inner rotor core 3 are fixedly connected to the rotor shaft 4 , so that the outer rotor core 1 and the inner rotor core 3 rotate together with the rotor shaft 4 . When setting, install the radially outer side of the outer rotor core 1 on the outer end of the rotor shaft 4, place the eccentric permanent magnets 2 alternately along the radially inner side of the outer rotor core 1, and magnetize two adjacent eccentric permanent magnets 2 in the opposite direction. Install the radially inner side of the inner rotor core 3 on the inner end of the rotor shaft 4, so that the annular air...

Embodiment 2

[0058] Embodiment 2 discloses a square-wave rotor designed based on a permanent magnet and an eccentric structure of an inner rotor core used in a square-wave flywheel generator. Reference attached Figure 4 And attached Figure 5 , which includes an outer rotor core 1, an eccentric permanent magnet 2, a magnetic isolation block 5, an inner rotor core 3 and a rotor shaft 4, and both the outer rotor core 1 and the inner rotor core 3 are fixedly connected to the rotor shaft 4, so that the outer rotor core 1 rotates together with the inner rotor core 3 and the rotor shaft 4. When setting, install the radially outer side of the outer rotor core 1 on the outer end of the rotor shaft 4, place the eccentric permanent magnets 2 alternately along the radially inner side of the outer rotor core 1, and magnetize two adjacent eccentric permanent magnets 2 in the opposite direction. The magnetic spacers 5 are tile-shaped, and placed between two adjacent eccentric permanent magnets 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com