Permanent magnet synchronous motor with limited rotation angle

A technology of permanent magnet synchronous motor and limited rotation angle, which is applied to synchronous motors with rotating armature and stationary magnets, electrical components, electromechanical devices, etc., which can solve the problems of high torque density and cramped space, etc. High moment density, improved efficiency, low speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

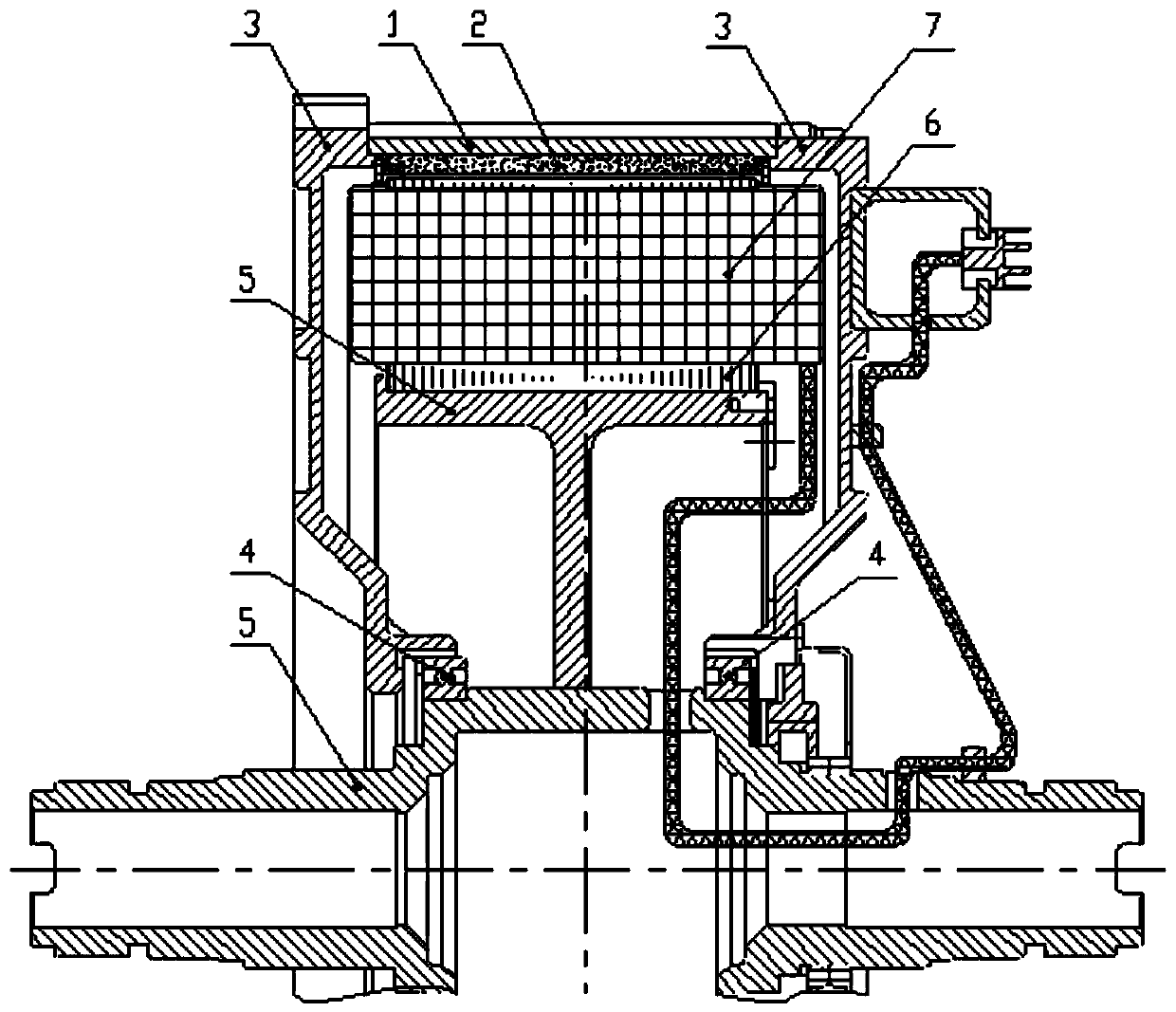

[0035] A limited rotation angle permanent magnet synchronous motor, comprising: a base 1, a permanent magnet 2, an end cover 3; a bearing 4, a rotating shaft 5, an armature core 6, an armature winding 7, and a permanent magnet fixing ring, such as figure 1 As shown; the base 1 is connected with the end cover 3; the permanent magnet 2 is installed on the inner side of the base 1, and the base 1, the permanent magnet 2, and the end cover 3 integrally form a stator; the rotating shaft 5 passes through the bearing 4 is connected with the end cover 3; the armature core 6 is set on the rotating shaft 5; a groove is provided in the armature core 6, and the armature winding 7 is installed in the groove, and the rotating shaft 5. The armature core 6 and the armature winding 7 integrally constitute the rotor; the armature core 6 is located inside the permanent magnet 2 , and a gap is provided between the armature core 6 and the permanent magnet 2 . The permanent magnet fixing ring is in...

Embodiment 2

[0042] A permanent magnet synchronous motor with a limited rotation angle is composed of a base 1, a permanent magnet 2, front and rear end covers, front and rear bearings, inner and outer rotating shafts, an armature core 6 and an armature winding 7.

[0043] The armature core 6 is made of stacked high-permeability silicon steel sheets with armature slots. The armature winding 7 is made of high-conductivity materials and embedded in the armature slots of the armature core 6. The winding armature core 6 is shrunk on the outer shaft made of aluminum alloy through interference fit, and the outer shaft and the inner shaft made of No. 45 steel are connected by hinged hole bolts. The overall composition The motor rotor part and the outer shaft part are made of aluminum alloy, which can reduce the weight and moment of inertia of the motor rotor.

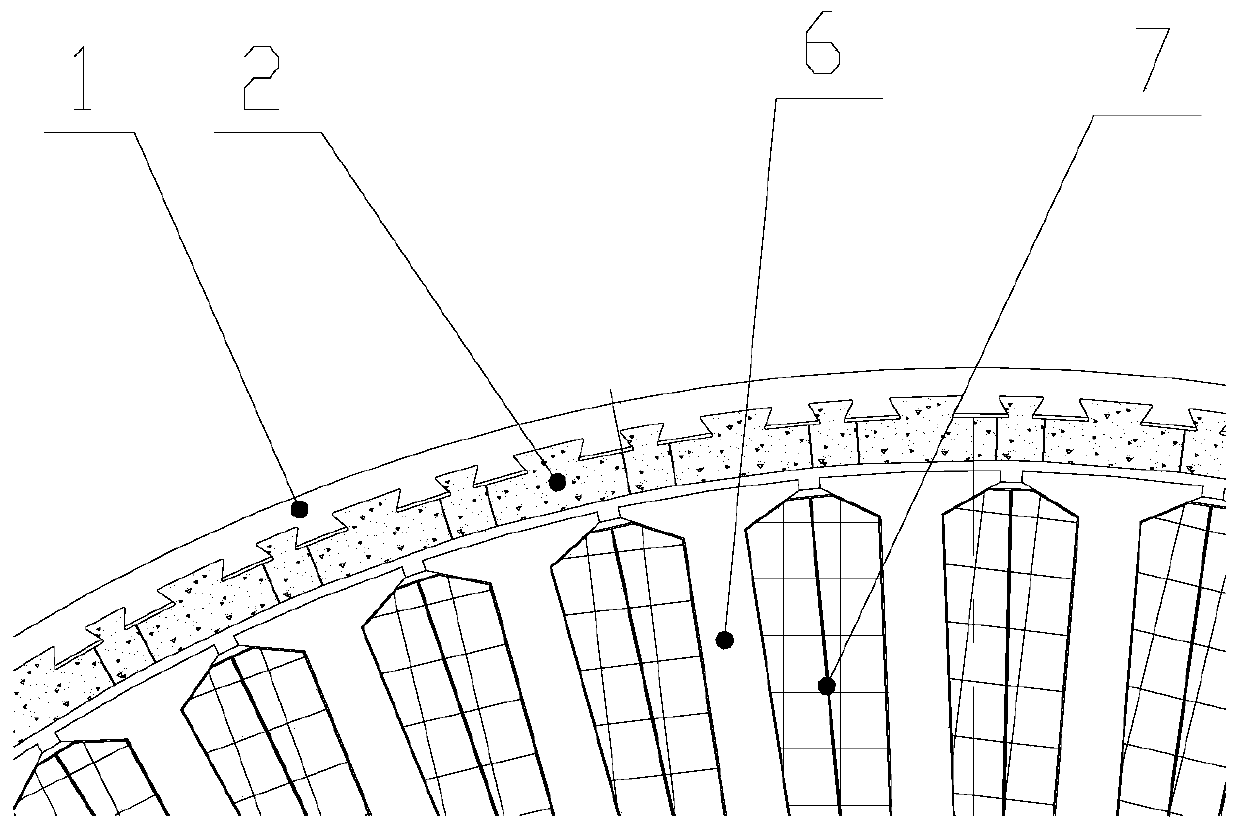

[0044] Machine base 1 is made of No. 10 steel material. On the inner circle of machine base 1, there are dovetail grooves with twice the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com