Rotor of permanent magnet motor, permanent magnet motor and compressor

A permanent magnet motor and rotor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit, electrical components, etc., can solve the problem of difficult saturation of permanent magnet magnetization, reduce harmonic content, improve air gap flux density waveform, Improve the effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

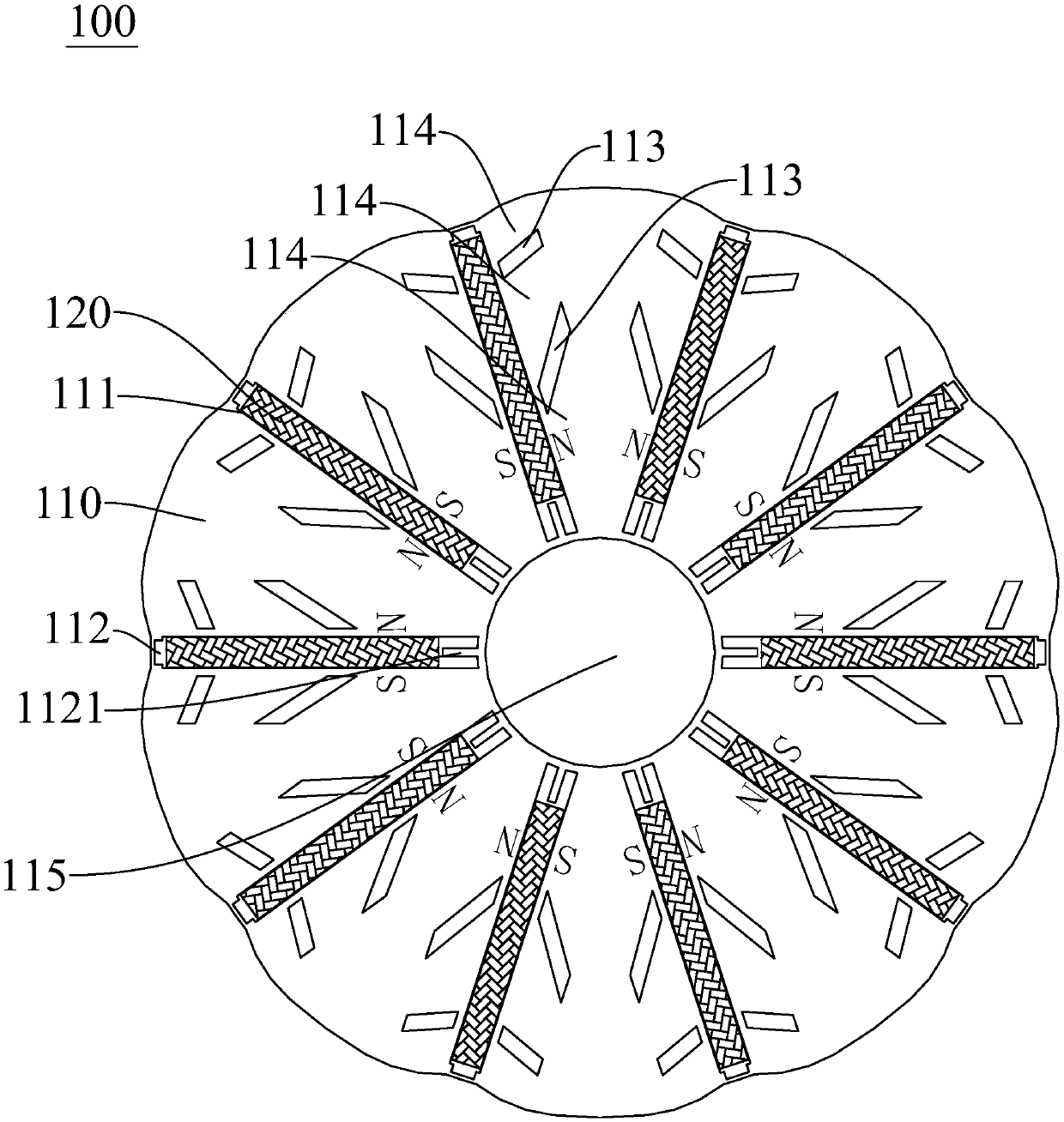

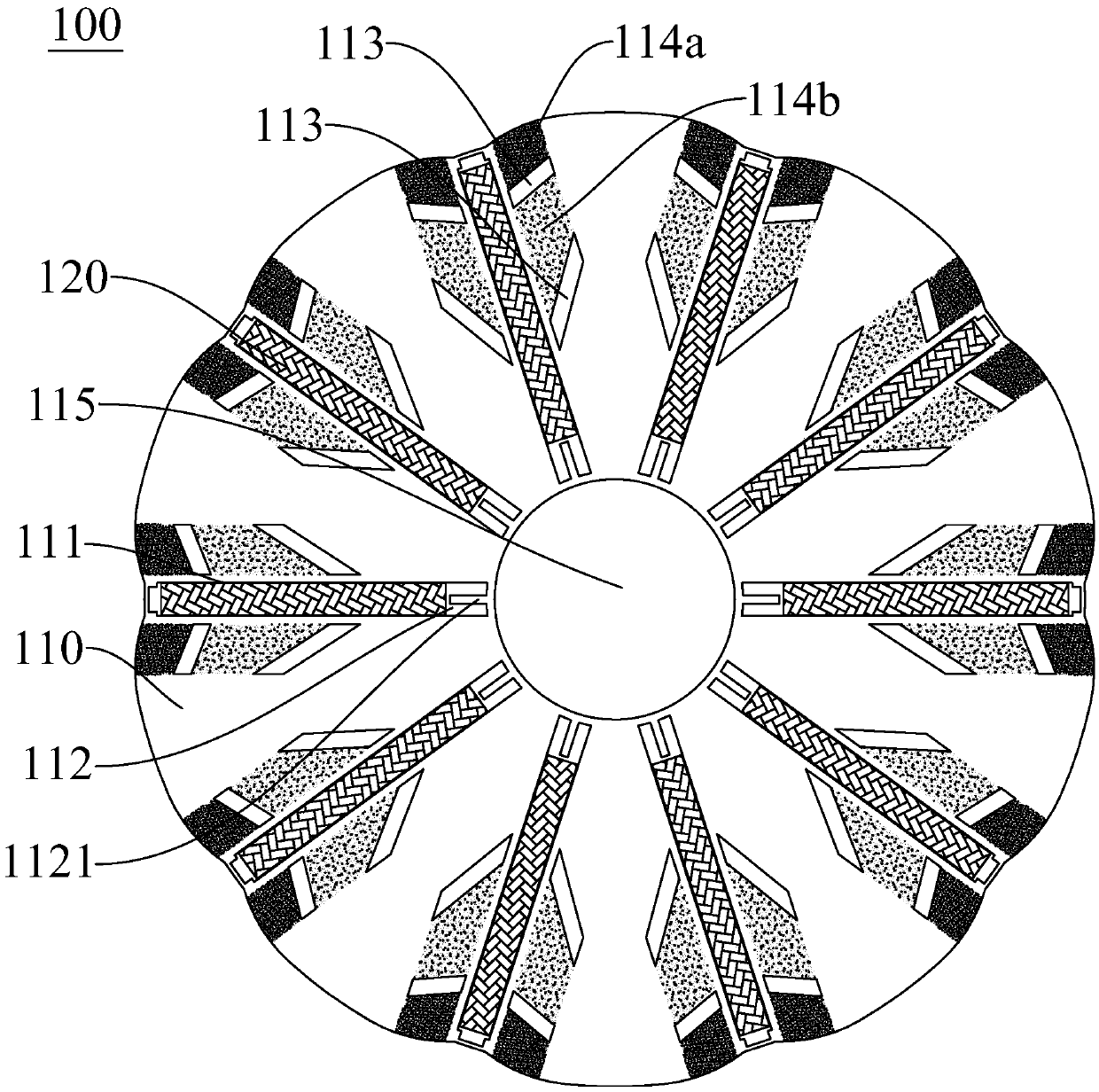

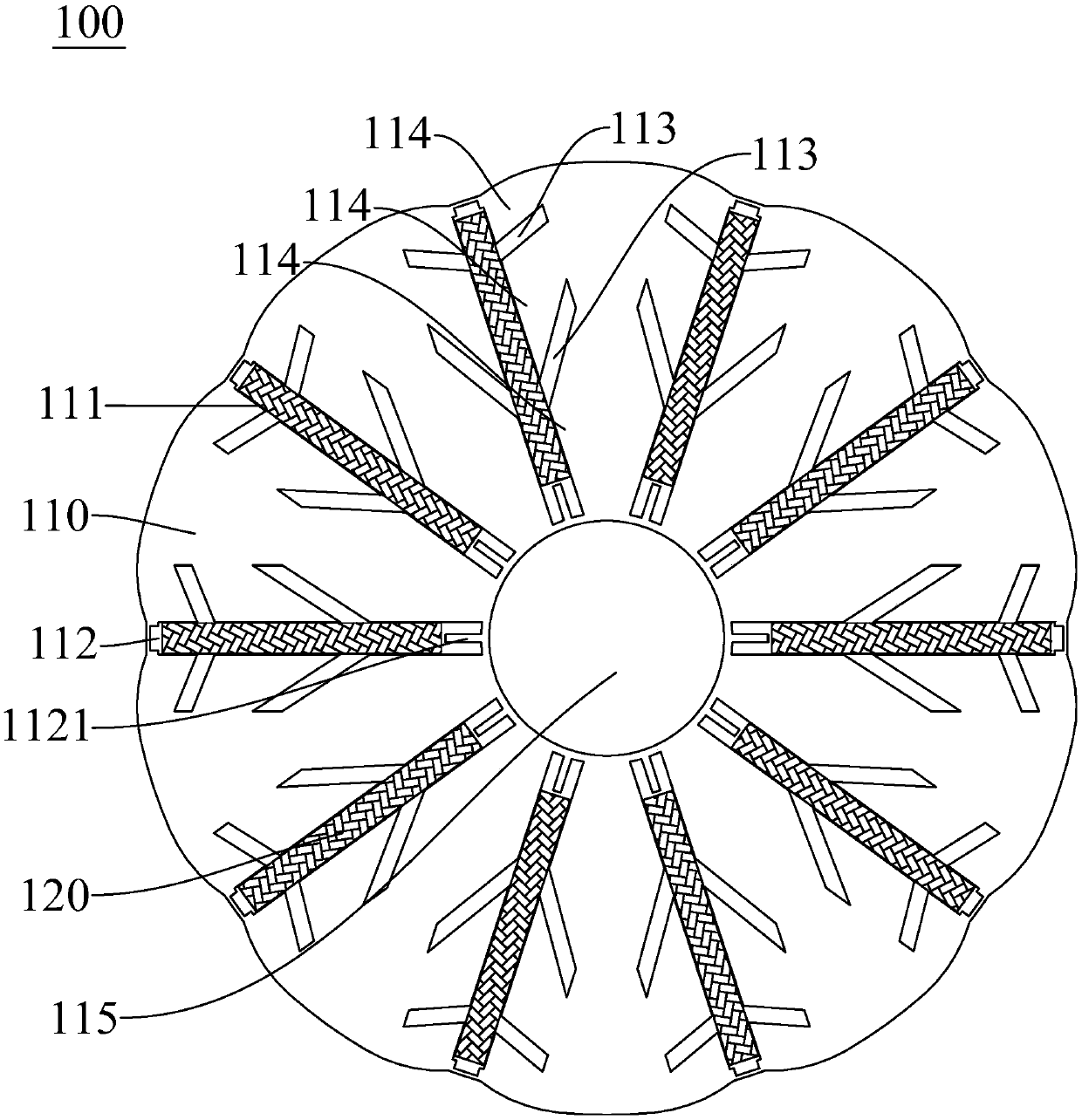

[0061] Refer below Figure 1-Figure 2 A rotor 100 of a permanent magnet motor according to a specific embodiment of the present invention is described.

[0062] Such as figure 1 As shown, the rotor 100 of the permanent magnet motor of this embodiment includes a rotor core 110 and ten permanent magnets 120, the rotor core 110 has a central hole 115 and ten magnet slots 111, and the ten magnet slots 111 are along the center hole 115. Circumferentially arranged, each magnet slot 111 extends along the radial direction of the central hole 115, and ten permanent magnets 120 are inserted in a plurality of magnet slots 111 one by one, and each magnet slot 111 is located in each permanent magnet Parts at both ends of the radial direction of 120 form first magnetic isolation slots 112 . The inner wall of the first magnetic separation slot 112 located radially inside the permanent magnet 120 facing the center of the rotor core 110 has an elongated protrusion 1121 protruding radially ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com