A Rotor Structure for Improving Air Gap Flux Density Waveform of 2-pole Self-starting Permanent Magnet Motor

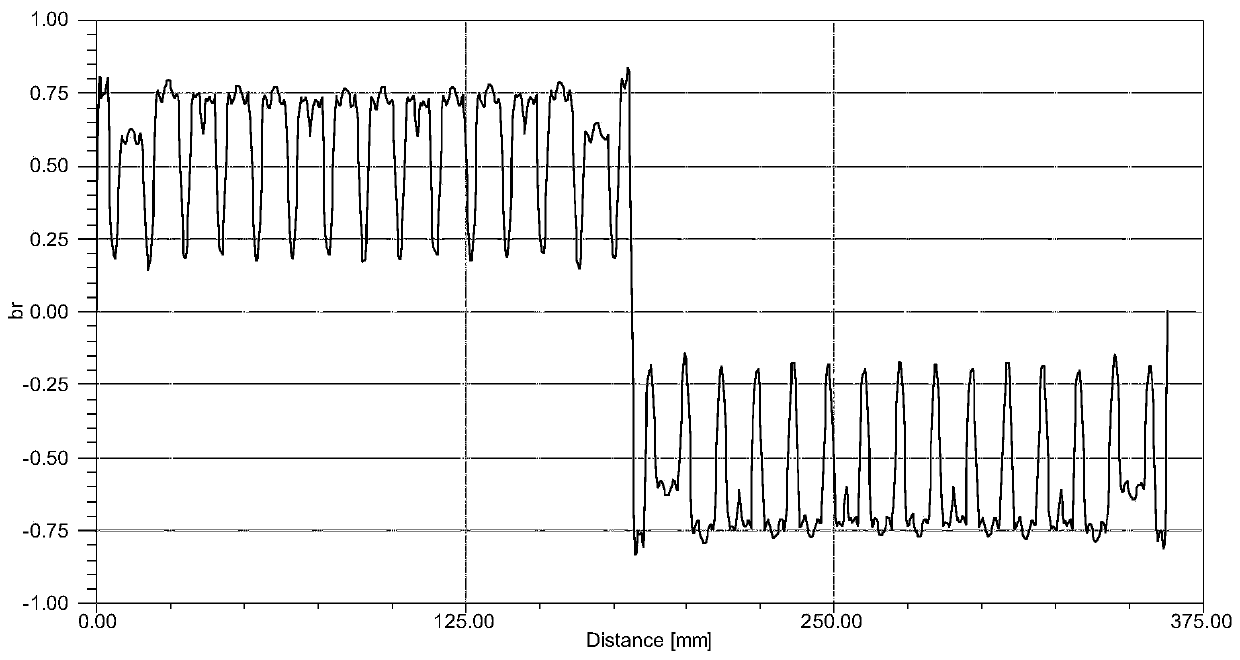

An air-gap magnetic density, permanent magnet motor technology, applied in the magnetic circuit shape/style/structure, manufacturing stator/rotor body, magnetic circuit rotating parts, etc., can solve the problem of weakening the harmonic magnetic field, complex magnetic pole structure, increasing motor Stator harmonic current, harmonic copper loss, stator core harmonic loss, etc., to optimize the air-gap flux density waveform, overcome the limited rotor space, and reduce the torque ripple of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

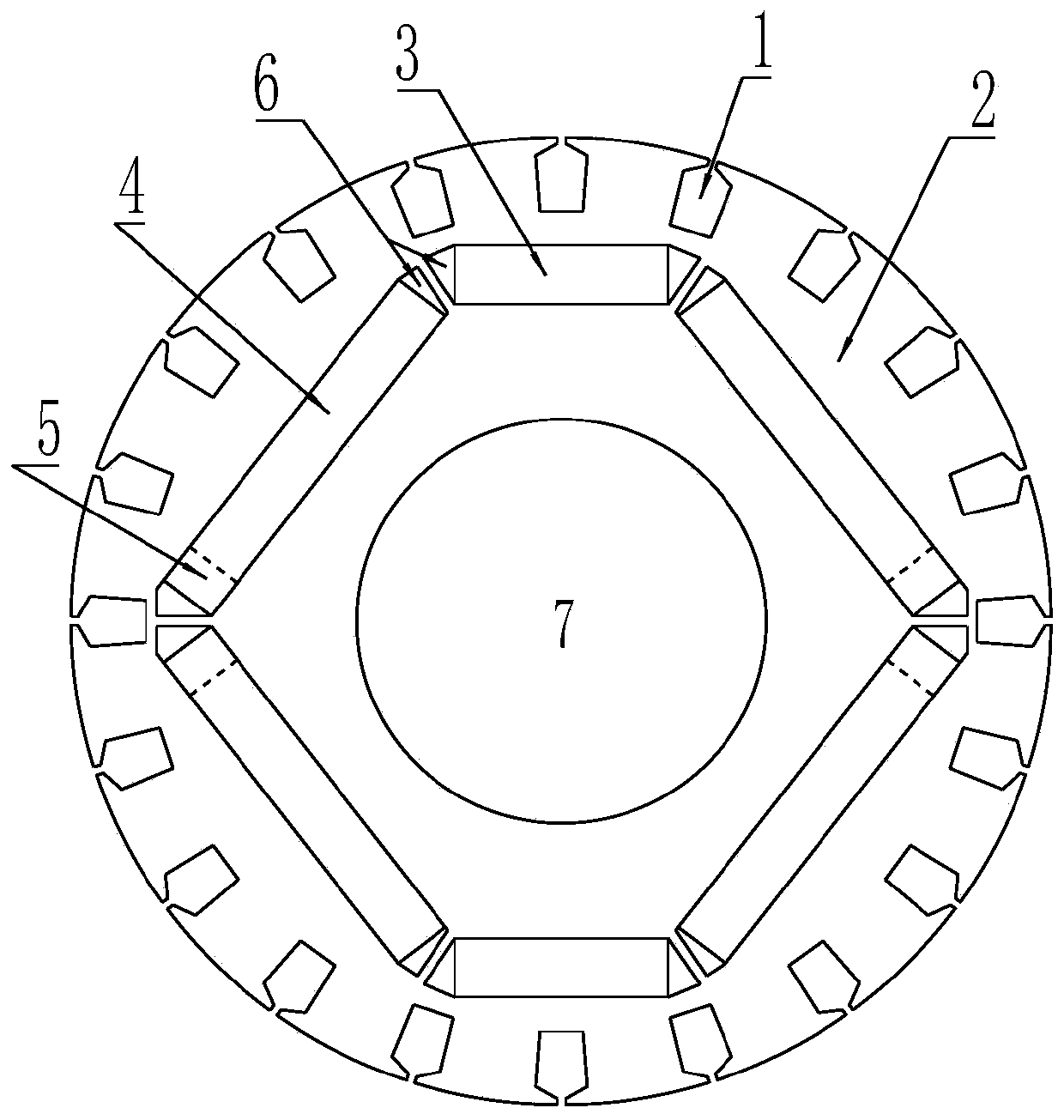

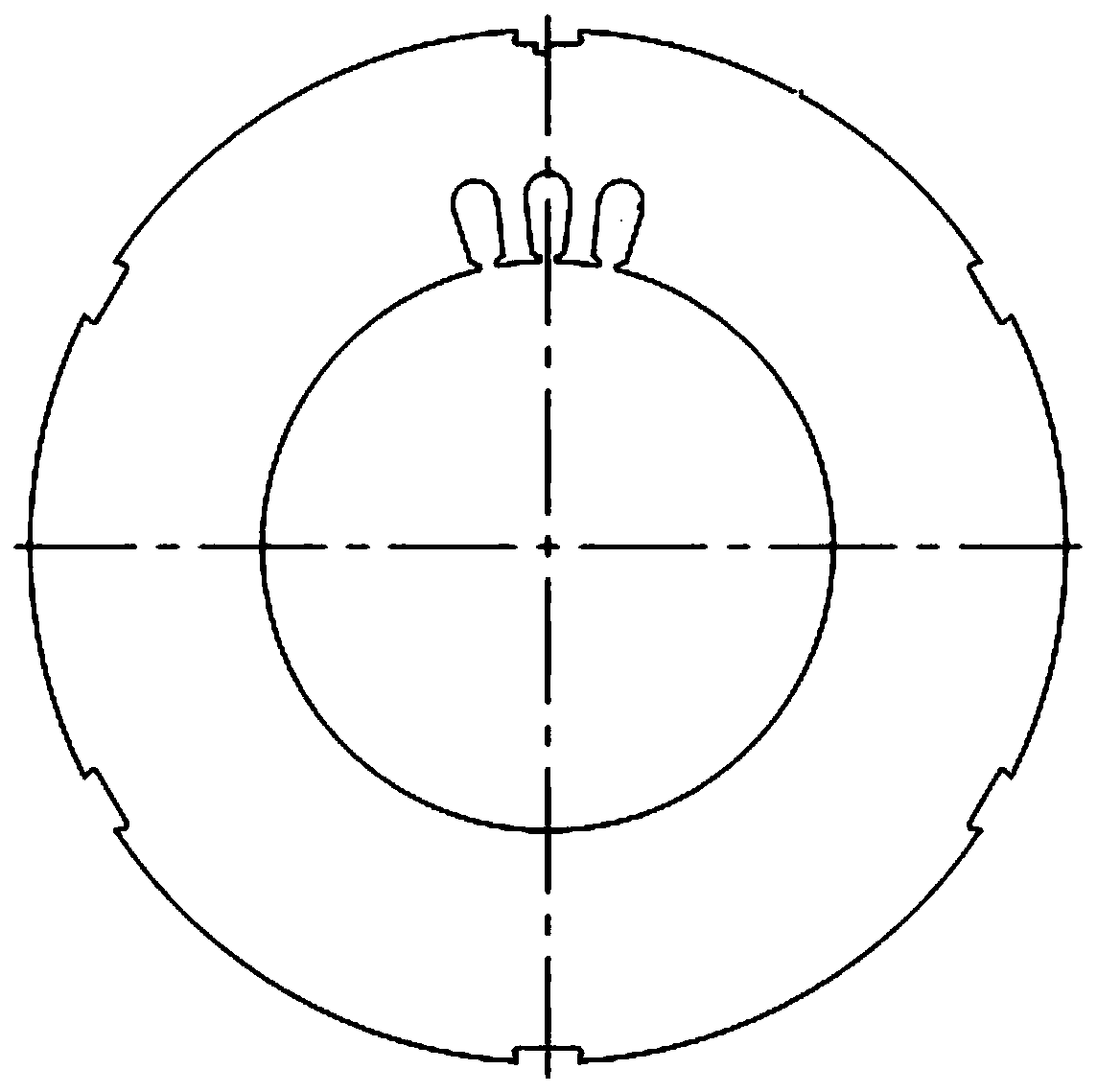

[0031] Take a 132 frame size 7.5kW, 2-pole self-starting permanent magnet motor as an example, the stator of the motor adopts the standard Y2 series stator punching, such as figure 2 Shown; Rotor stamping adopts a kind of structure that the present invention provides to improve 2-pole self-starting permanent magnet motor air-gap magnetic density waveform, as figure 1 As shown, it includes a rotor core 2 with several squirrel cage slots 1 and permanent magnets installed in the permanent magnet slots. The permanent magnets under the two poles all adopt a three-stage inverted "U"-shaped magnetic circuit structure, which is divided into the middle One section of permanent magnet 3 and two sections of side permanent magnets 4, between two adjacent sections of permanent magnets is an air groove 6, and the three sections of permanent magnets are left and right symmetrical about the center line of the middle section of permanent magnets 3, and the two sections of side permanent magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com