Stator of a winding dislocation hub motor and a winding dislocation hub motor device

A technology for in-wheel motors and windings, which is applied to the shape/style/structure of electromechanical devices, windings, and winding conductors to optimize the air-gap magnetic density waveform, reduce torque ripple, improve fundamental winding factor and magnetic unbalance The effect of suppressing the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

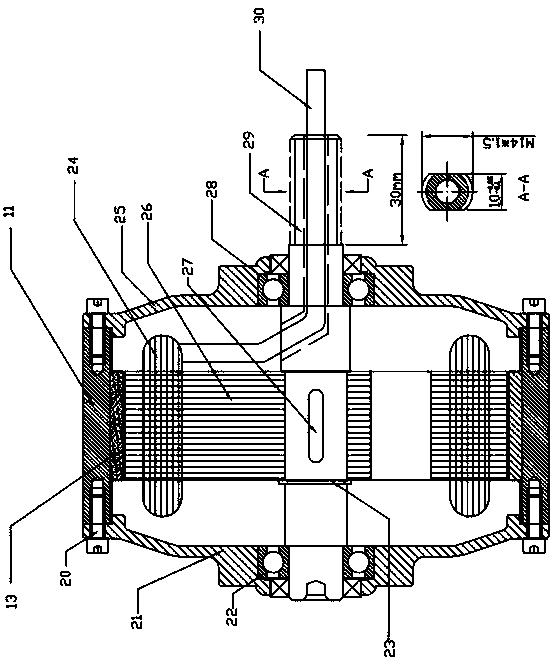

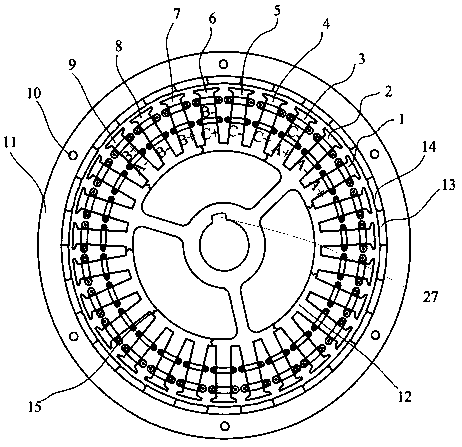

[0027] The accompanying drawings disclose the schematic structural diagrams involved in the present invention without limitation, and the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

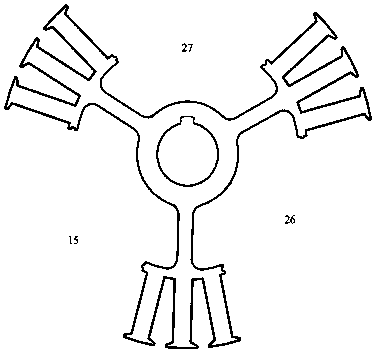

[0028] Such as Figure 1-2As shown, the winding dislocation hub motor device of the present invention includes a shaft 29, a stator bracket 26, a modular stator core 12, a three-phase dislocation winding 24, a three-phase wire 30 protruding from the end of the shaft 29, a rotor core 11, tile-shaped continuous pole permanent magnet 13, salient pole iron core 14 of sine + third harmonic shape, end cover 21, end cover 25, bearing 22, bearing 28, fastening pressing piece 23 and keyway 27, the shaft 29 is a hollow motor shaft, the stator bracket 26 is sleeved on the shaft 29, the shaft 29 and the stator bracket 26 are fixed through the keyway 27 to transmit torque, the diameter of the shaft on one side of the stator brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com