Linear and rotary motion converter for V-type magnetic pole

A technology of rotary motion and converter, which is applied in the field of V-shaped magnetic pole linear rotary motion converter, can solve the problems of reducing the service life of the converter, damaging the shaft and equipment, etc., and achieves the goal of optimizing waveform, avoiding noise and vibration, and improving utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

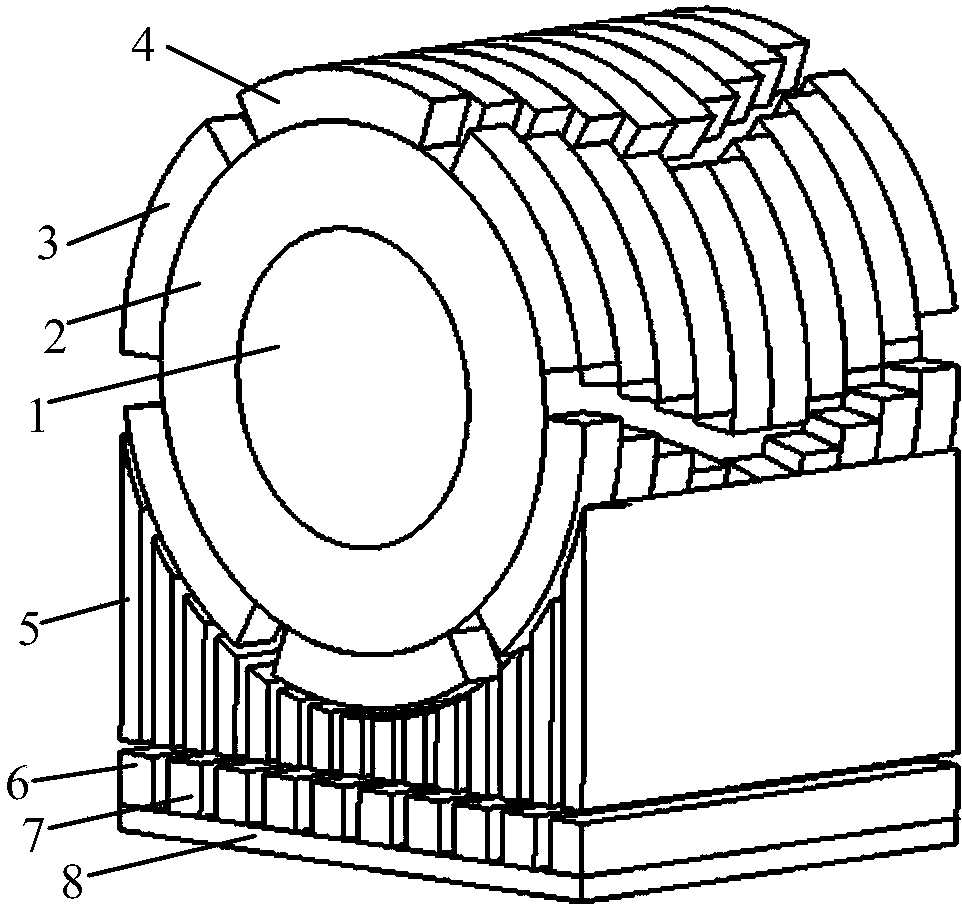

[0020] Embodiment 1: as figure 1 The shown V-shaped magnetic pole linear rotary motion converter includes a rotary unit, a linear unit and a magnetic modulation mechanism, and the magnetic modulation mechanism is fixedly arranged between the rotary unit and the linear unit.

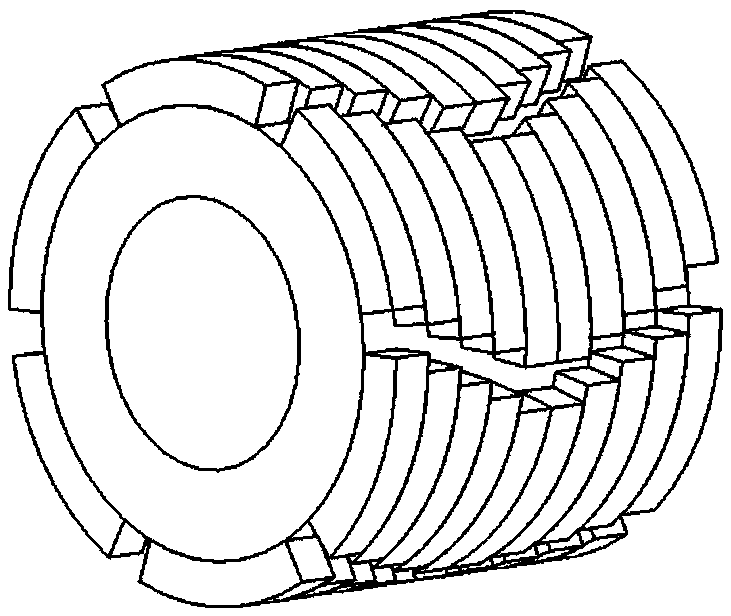

[0021] Such as figure 2 As shown, the rotating unit includes a rotating shaft 1, a rotor core 2 and permanent magnets. The rotating shaft 1 passes through the shaft hole of the rotor core 2 and is fastened together with the rotor core 2 , and the permanent magnet is pasted on the surface of the rotor core 2 . Wherein, the permanent magnets include a rotor N-pole permanent magnet 3 and a rotor S-pole permanent magnet 4, and the rotor N-pole permanent magnet 3 and the rotor S-pole permanent magnet 4 are radially magnetized tile-shaped permanent magnets. The permanent magnets of each pole of the rotating unit are arranged along the circumference of the rotor core 2 to form a multi-stage annular permanent ...

Embodiment 2

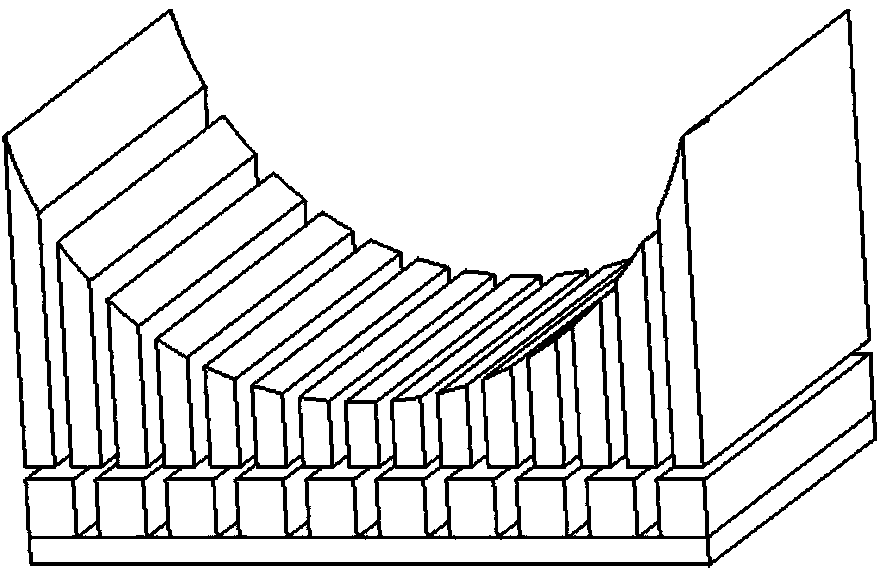

[0023] Embodiment 2: The only difference from Embodiment 1 is that the permanent magnet in the rotating unit is embedded in the rotor core 2 . The linear unit includes a mover yoke 8 and a mover N-pole permanent magnet 6 magnetized in the radial direction; the mover N-pole permanent magnet 6 is pasted on the surface of the mover yoke 8 along the moving direction of the linear unit. The N pole permanent magnet 6 of the mover and the S pole permanent magnet 7 of the mover in the linear unit are interlaced and embedded in the mover yoke 8 along the moving direction of the linear unit. In addition, the mover N-pole permanent magnet 6 in the mover yoke 8 can also be embedded in the mover yoke 8 along the moving direction of the linear unit.

[0024] In addition, the mover N pole permanent magnet 6 in the mover yoke 8 can also be replaced by the mover S pole permanent magnet 7 .

[0025] In this linear rotary motion converter, the magnetic lines of force generated by the permanent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com