Patents

Literature

63results about How to "Improve winding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

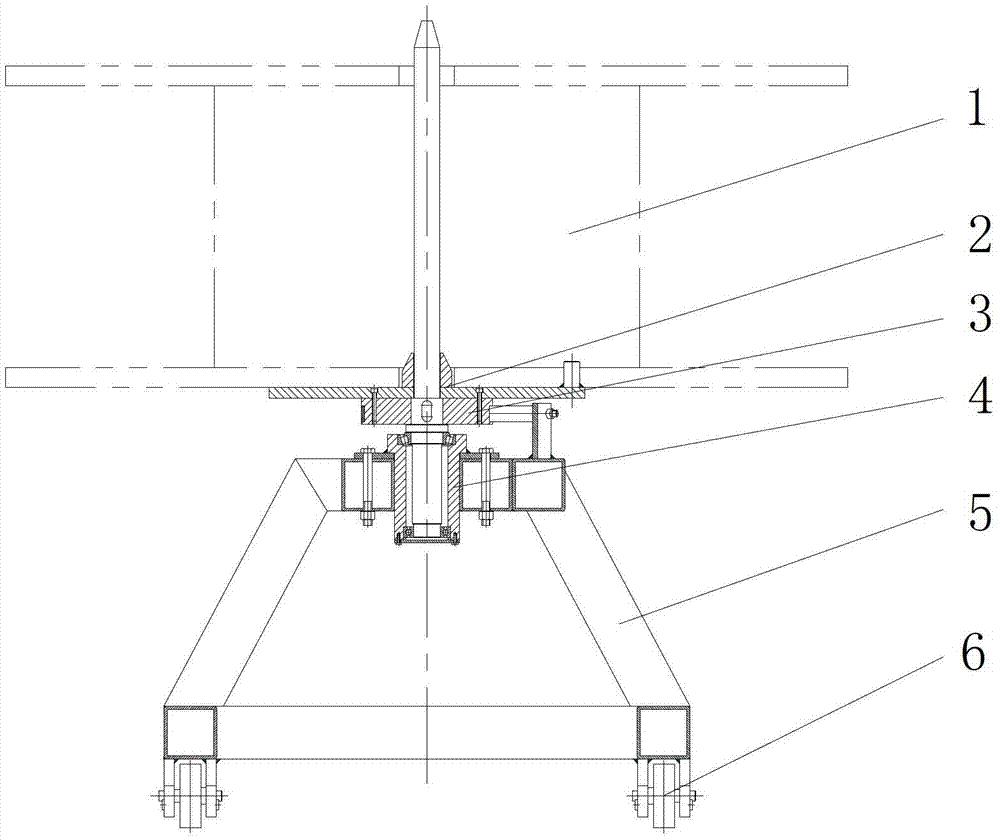

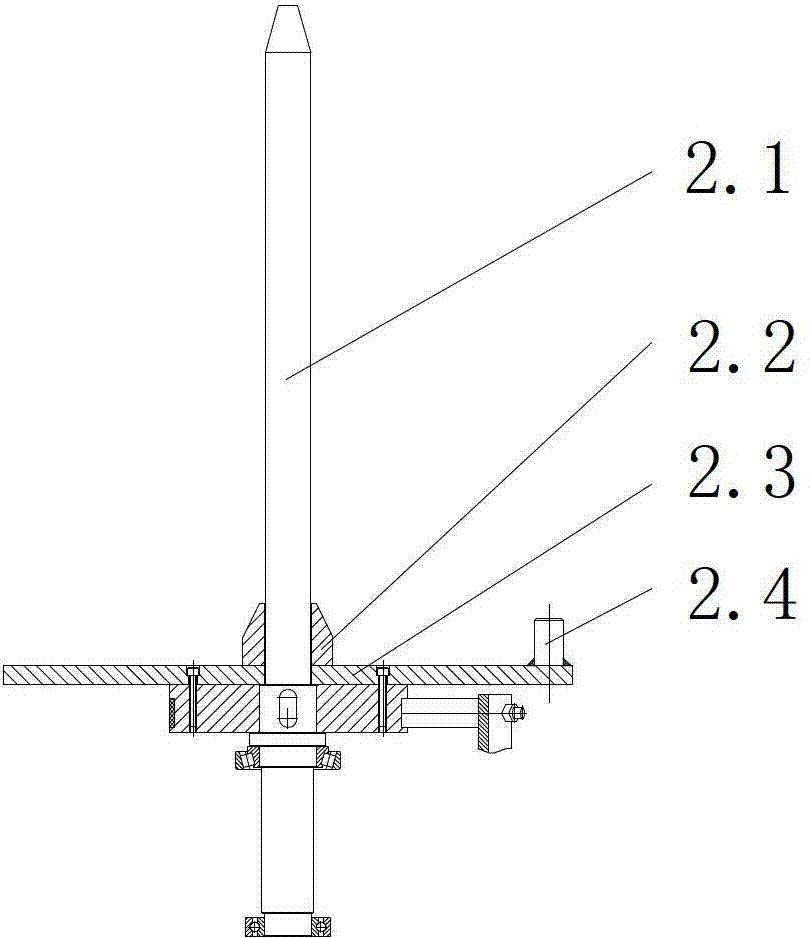

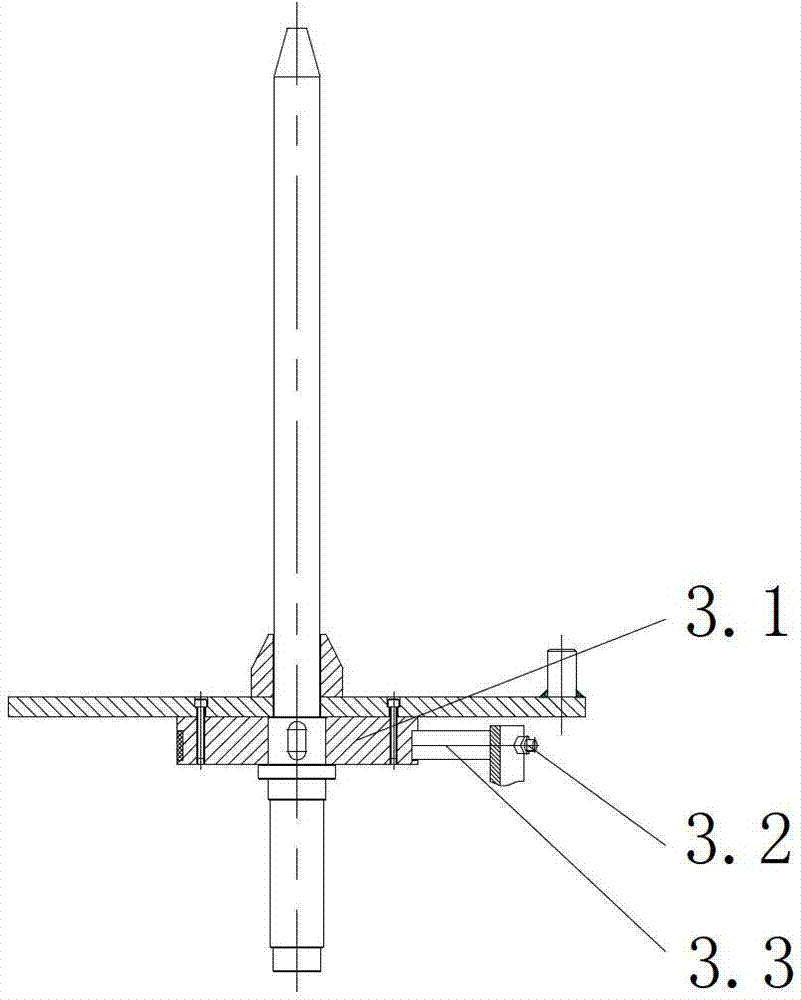

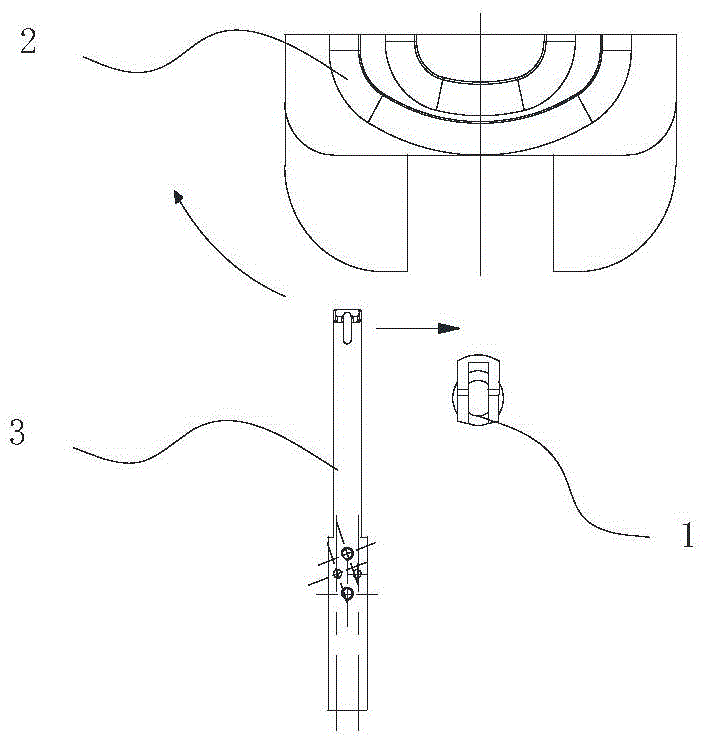

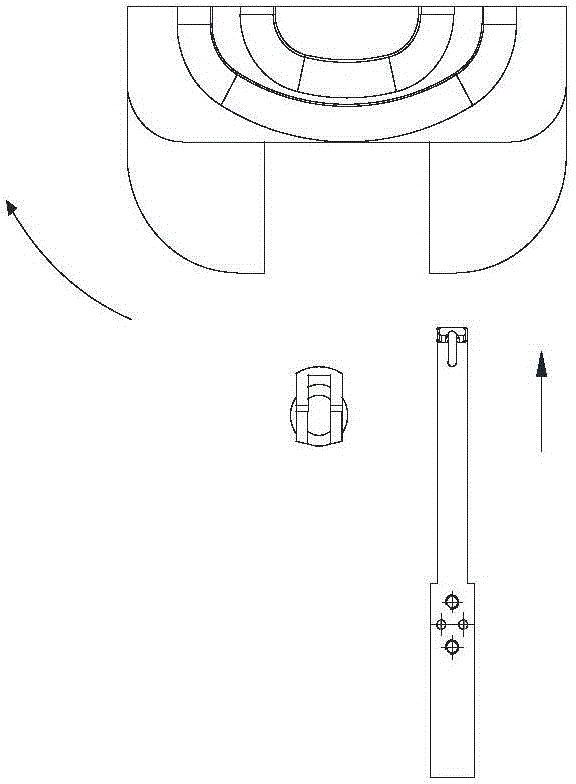

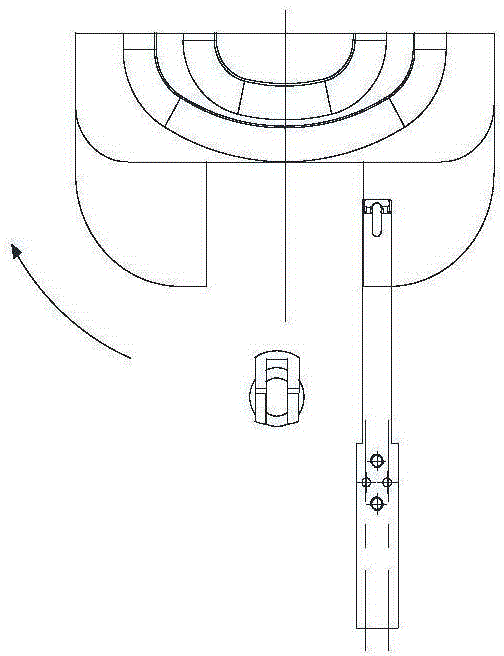

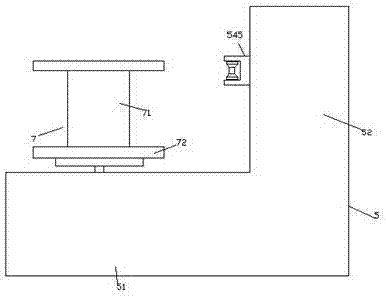

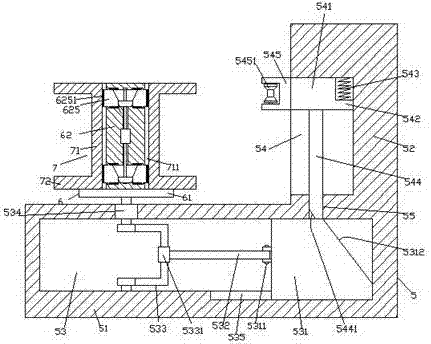

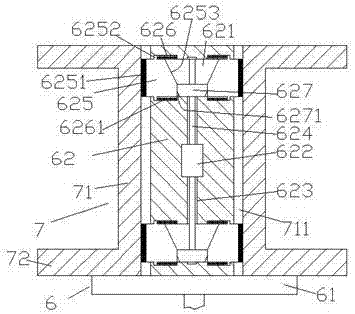

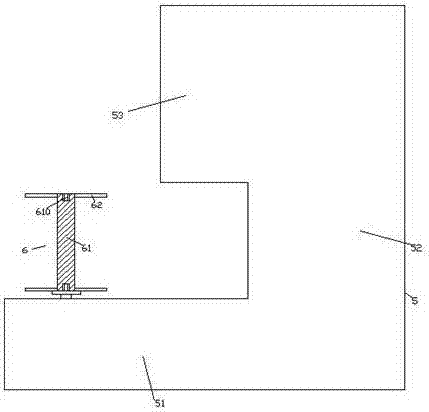

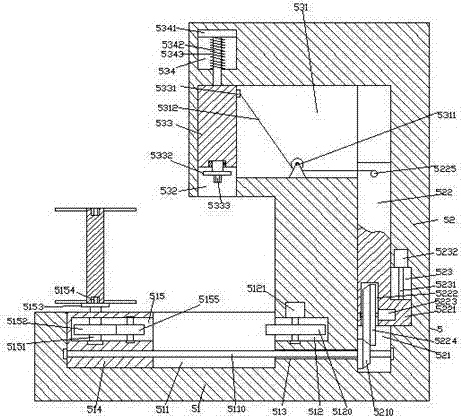

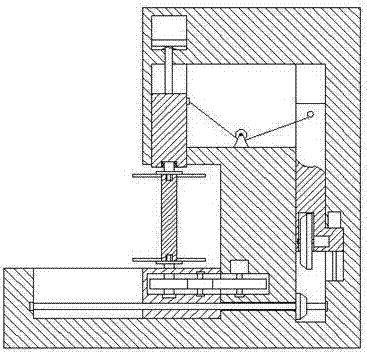

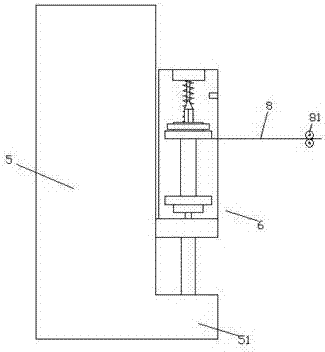

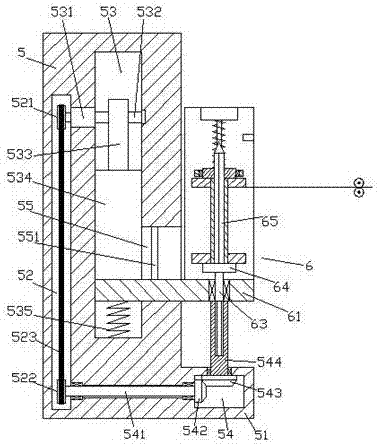

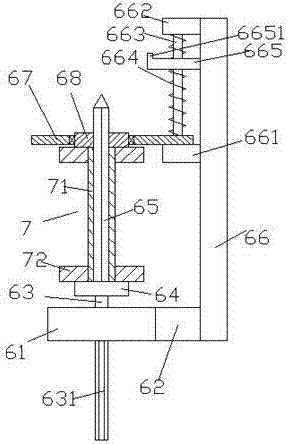

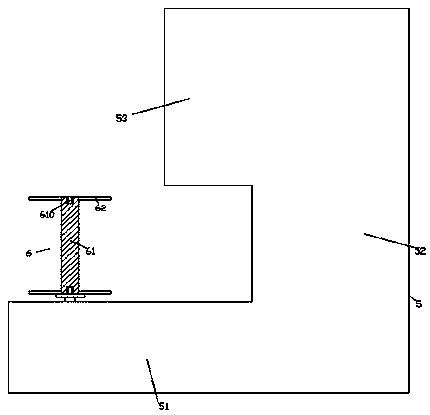

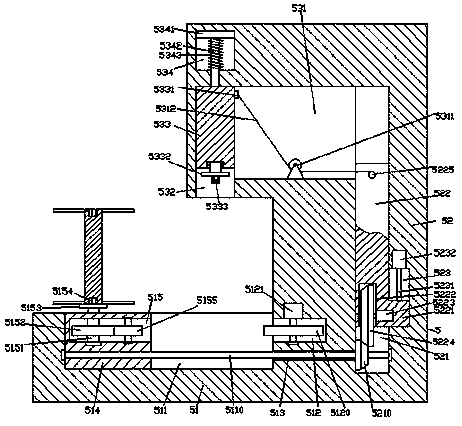

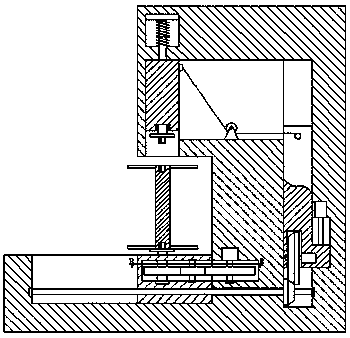

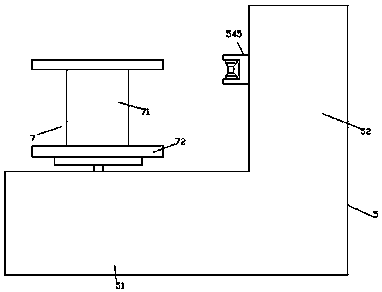

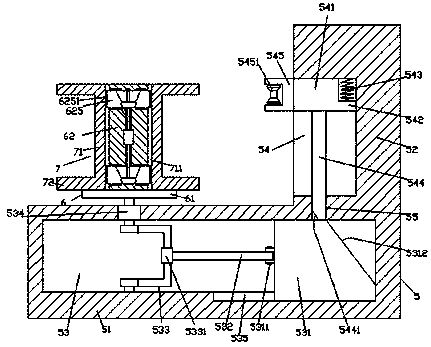

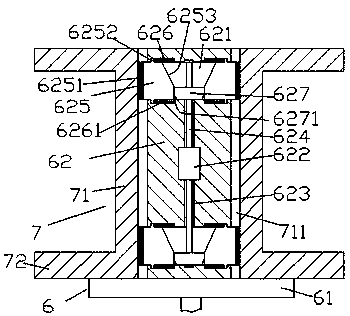

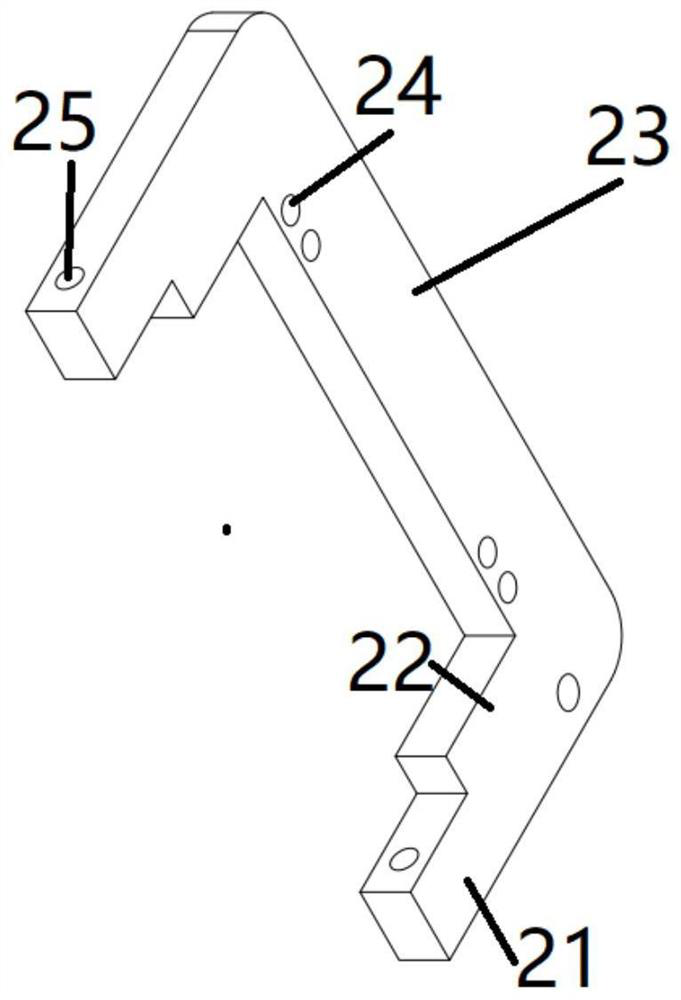

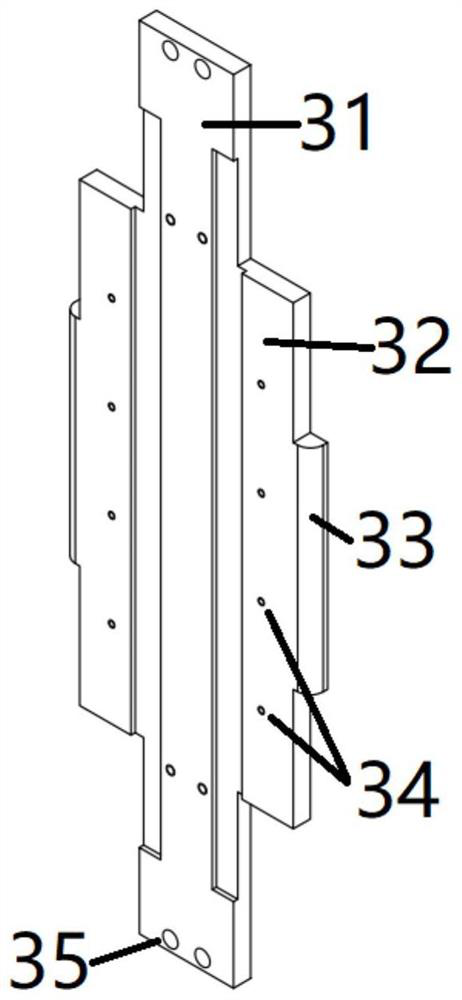

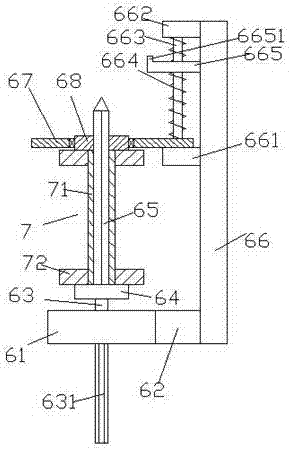

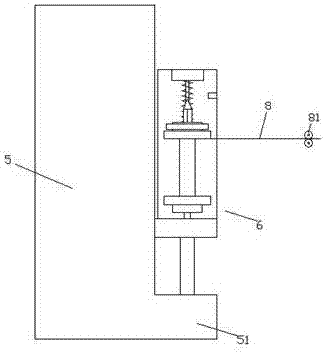

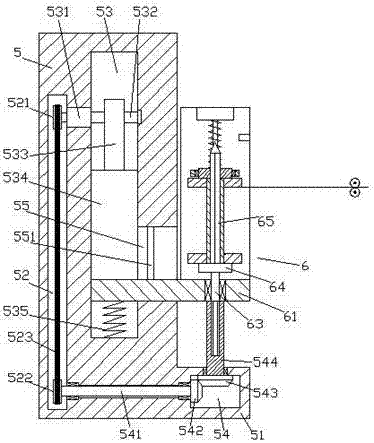

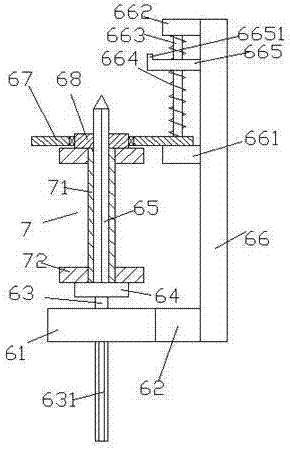

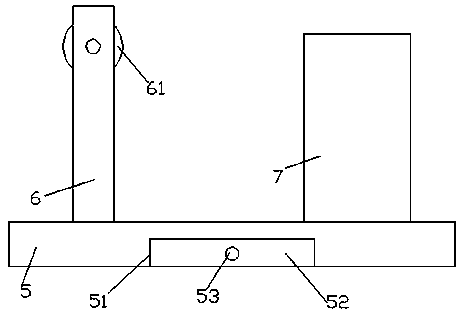

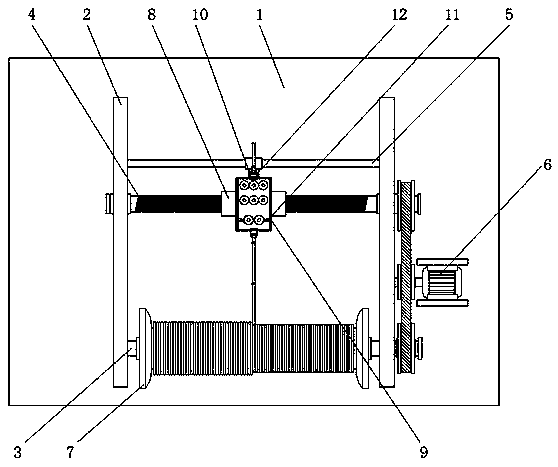

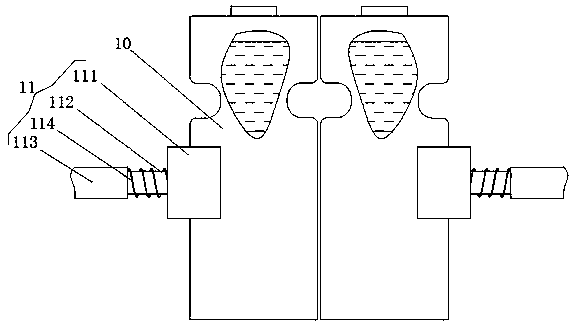

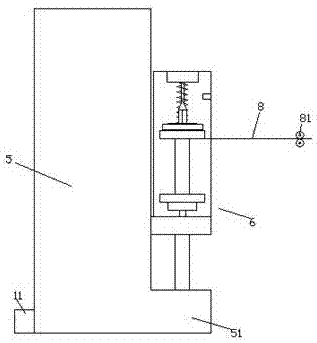

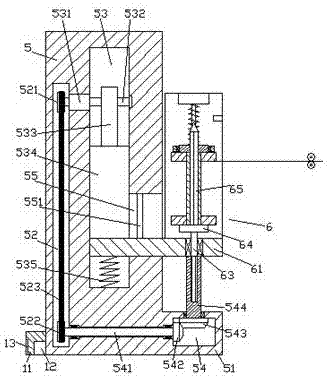

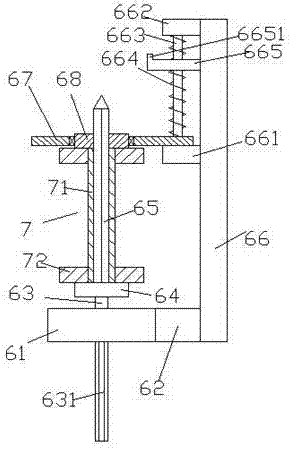

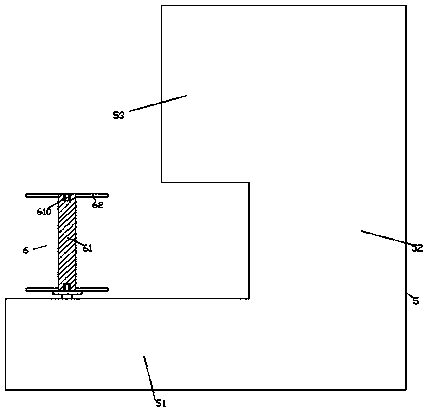

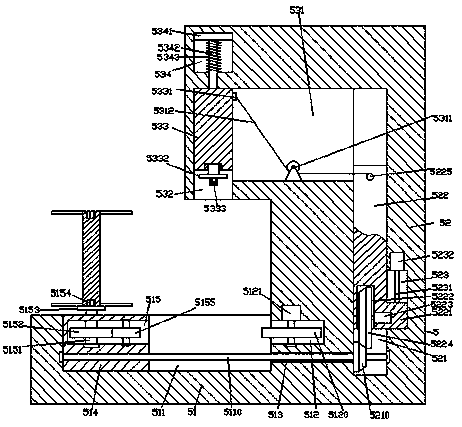

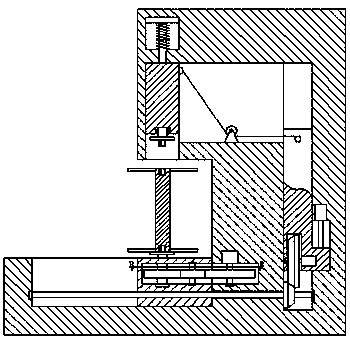

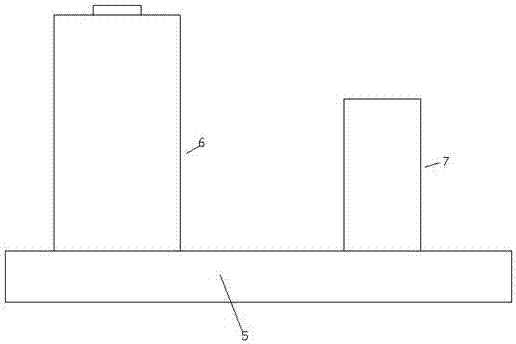

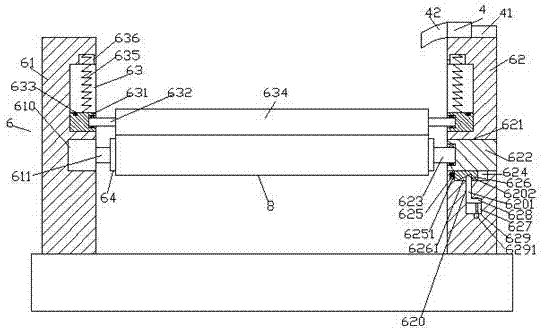

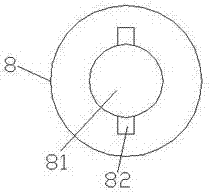

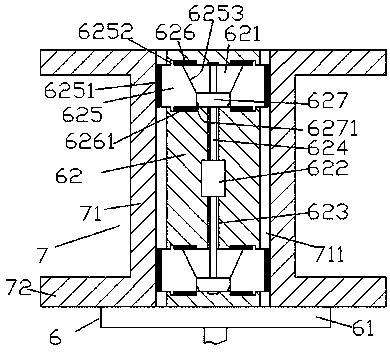

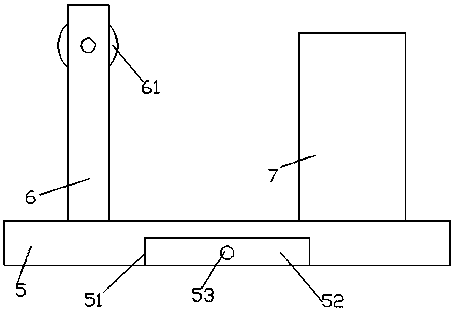

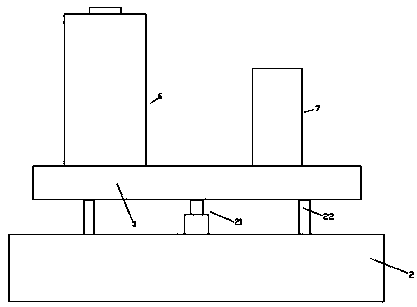

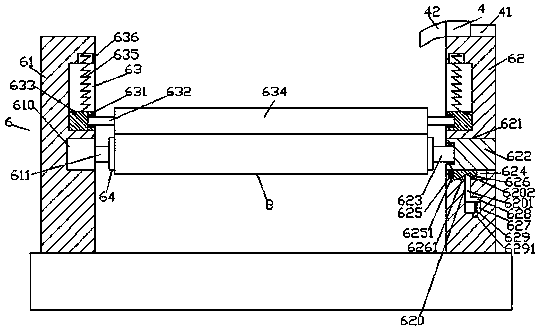

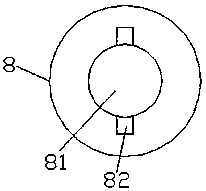

Paying-off tensioning equipment for vertical winding of transformer coil

InactiveCN103489624AImprove Tension DifficultyImprove the time-consuming and labor-intensive problems of wire reel installationFilament handlingCoils manufactureTransformerConductor Coil

The invention discloses paying-off tensioning equipment for vertical winding of a transformer coil. The paying-off tensioning equipment comprises a wire plate fixing device, a tensioning device, a bearing block device, a frame and a wheel device, wherein the wire plate fixing device is used for being vertically placed in the axial direction; a transposition guide wire plate is peripherally arranged on the wire plate fixing device; and the tensioning device is fixedly connected with the wire plate fixing device through a screw, and is used for controlling paying-off tensioning degree and the like of the tensioning equipment. By the paying-off tensioning equipment for vertical winding of the transformer coil, a large transposition guide wire plate can be vertically placed; by a guide wire tensioning structure, appropriate winding tensioning force can be obtained; the whole paying-off tensioning equipment is simple in structure, and is reasonable and practical; when a plurality of guide wires are wound in parallel, a plurality of paying-off tensioning devices can be arrayed, and the problem of poor manufacturability due to horizontal wire plates is solved.

Owner:SANBIAN SCI TECH

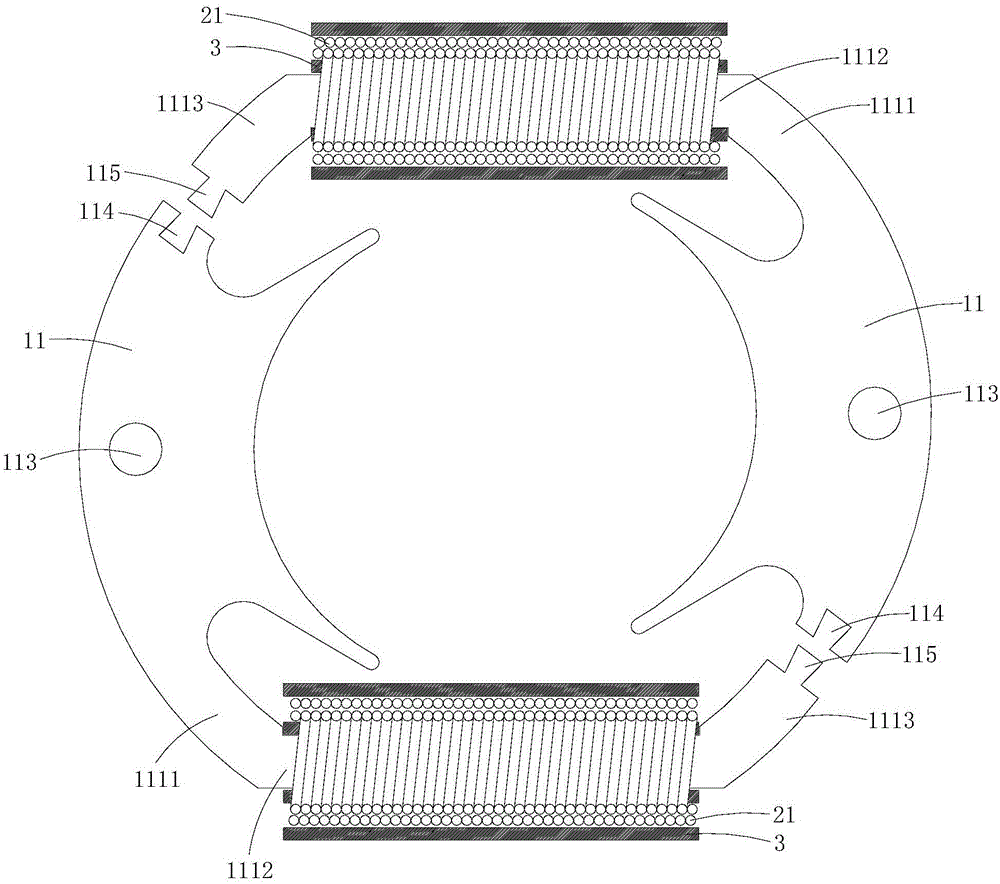

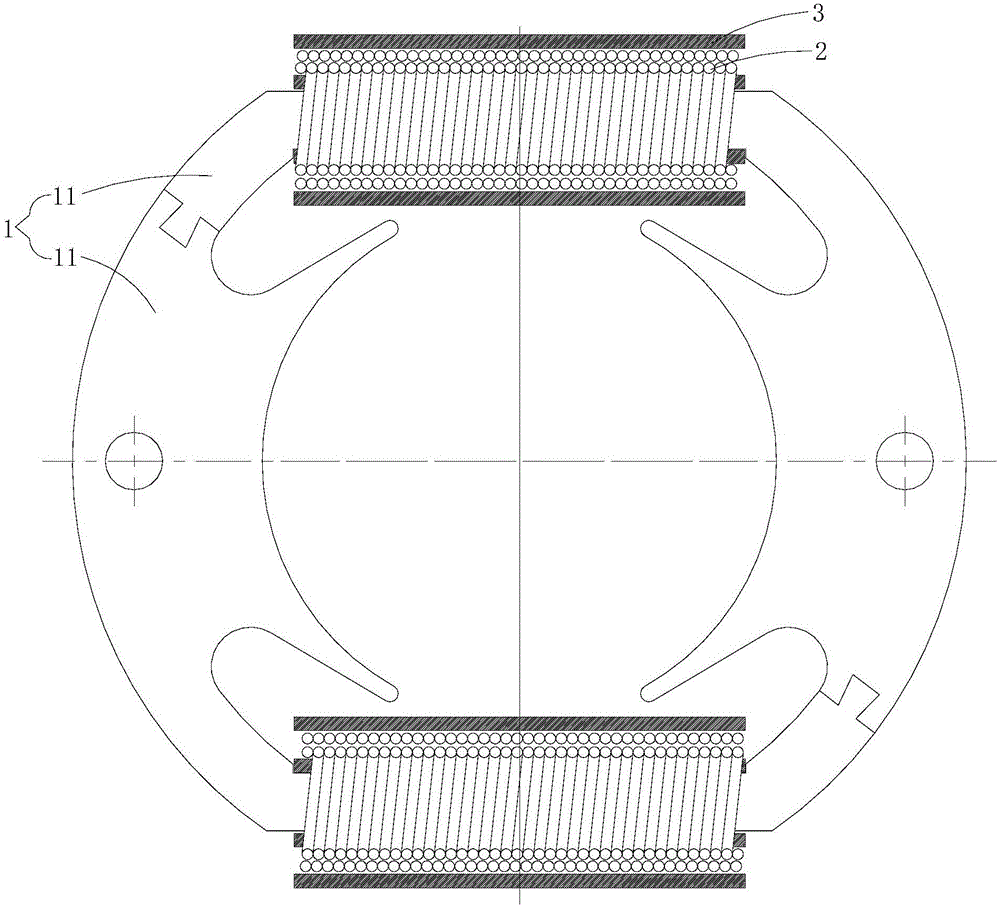

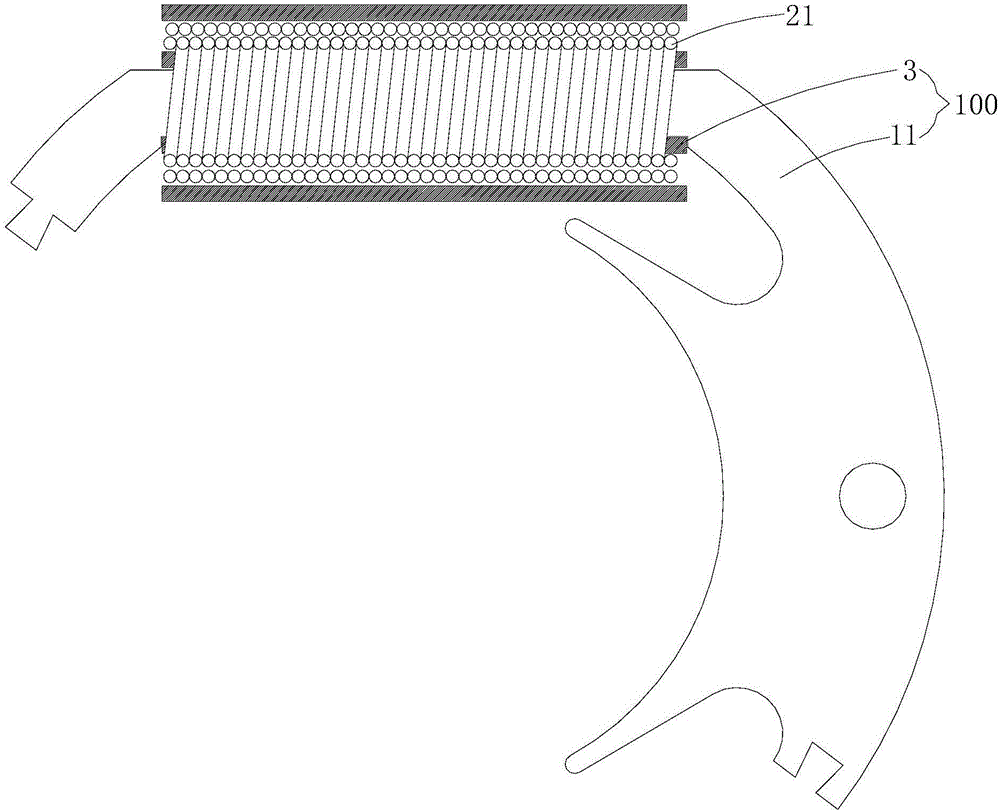

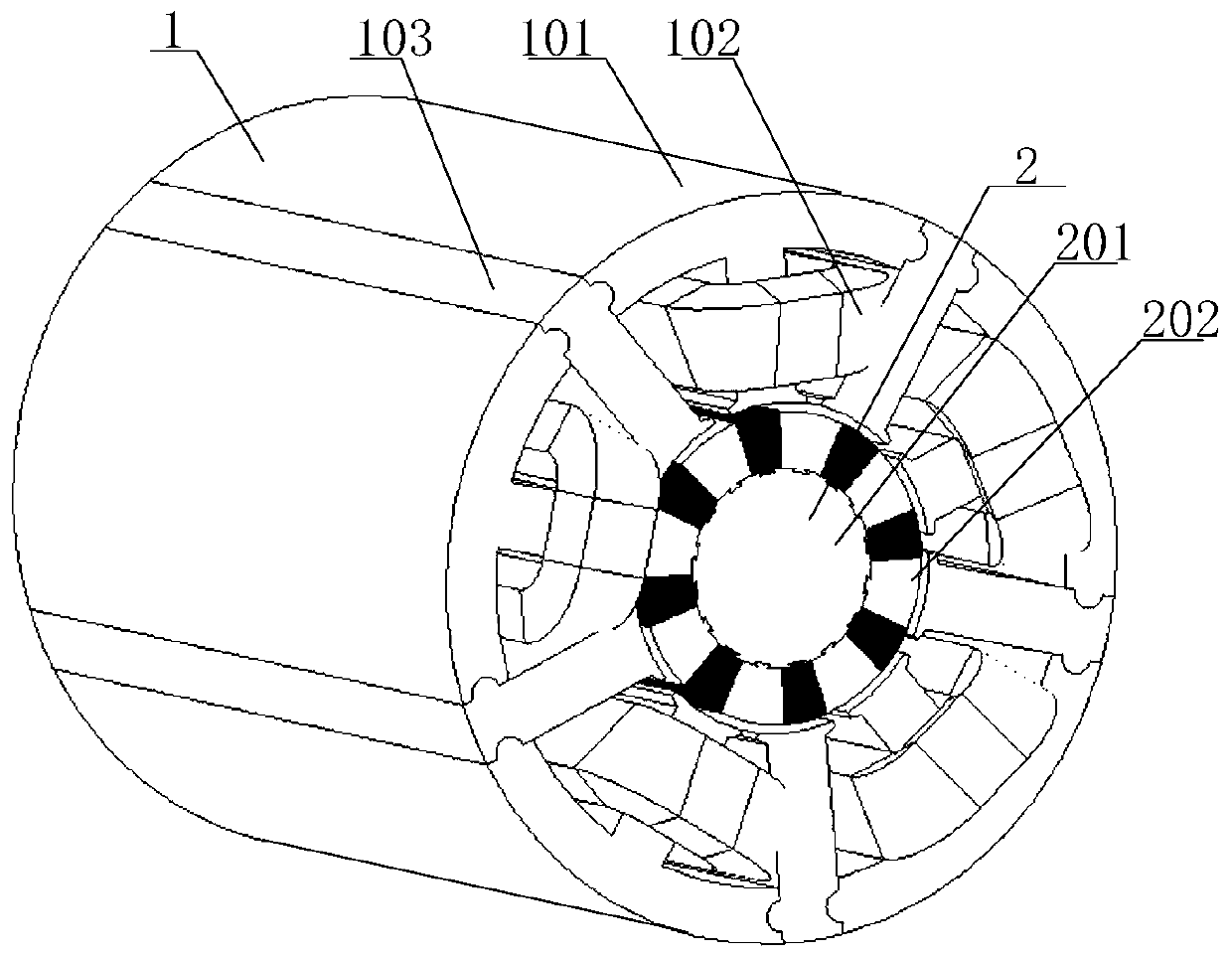

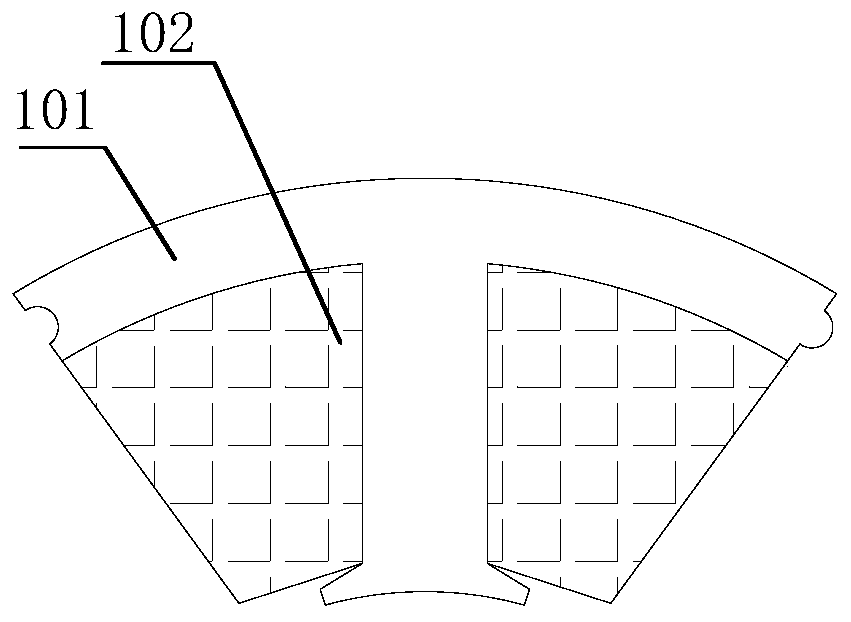

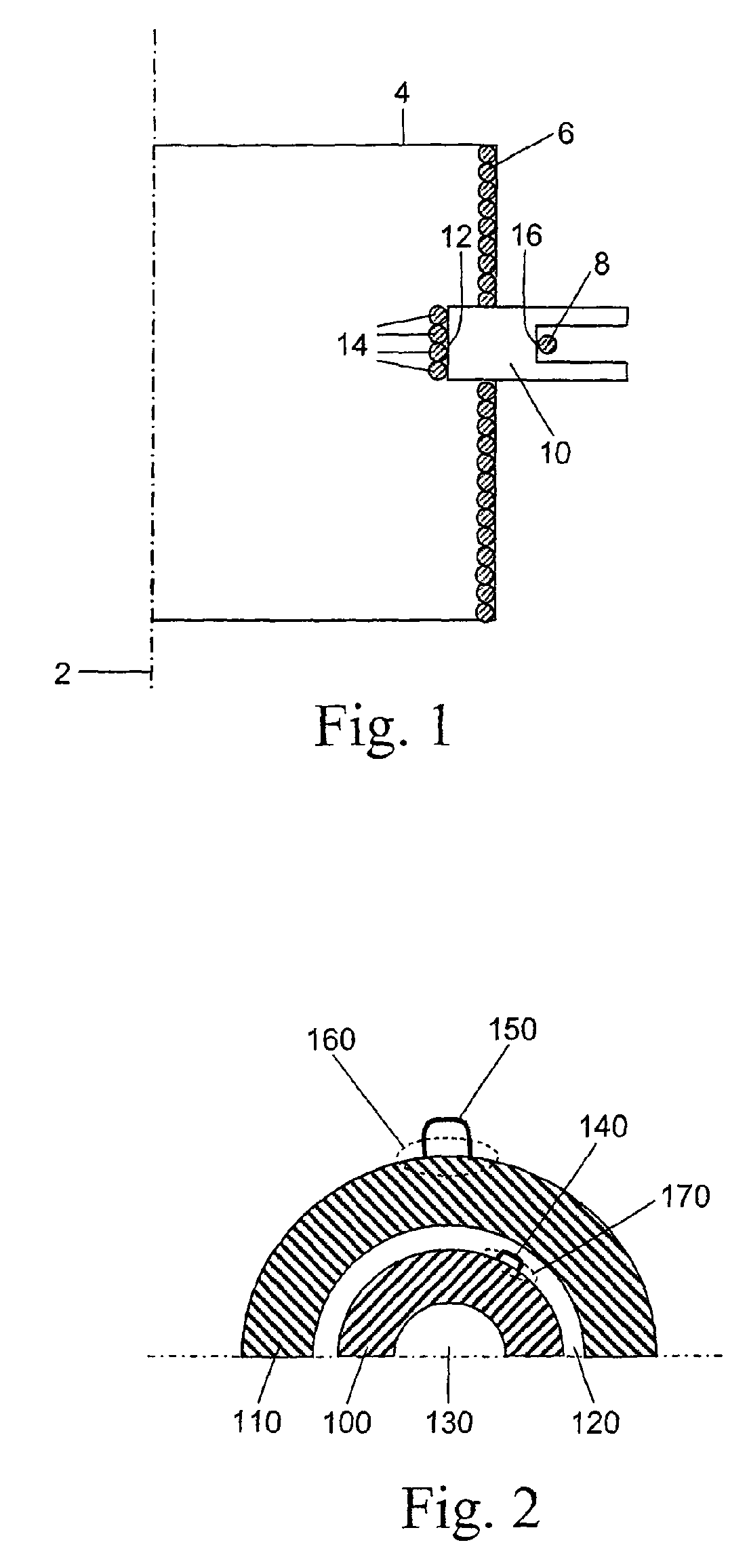

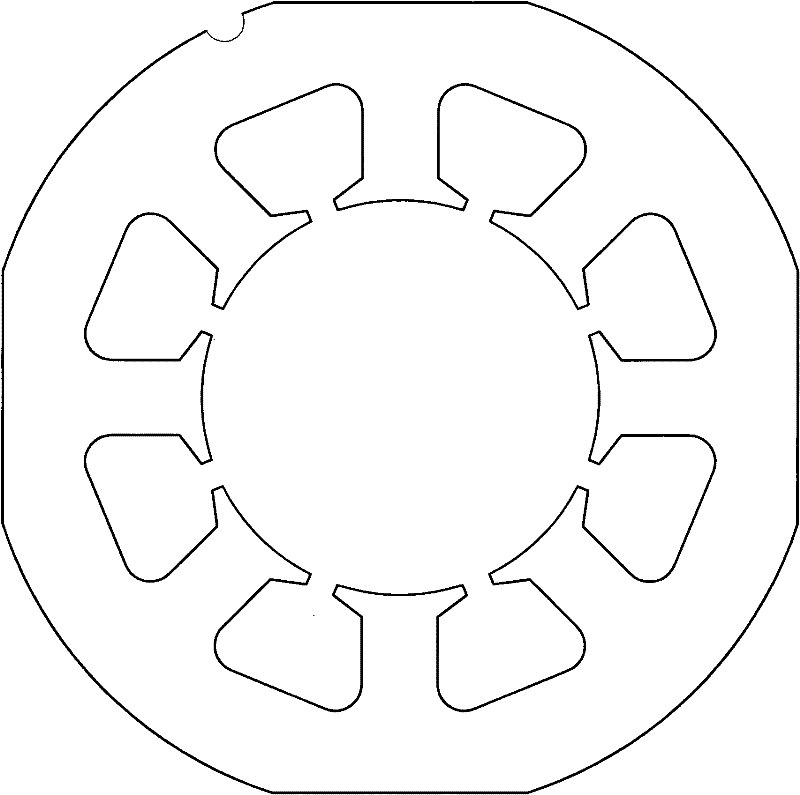

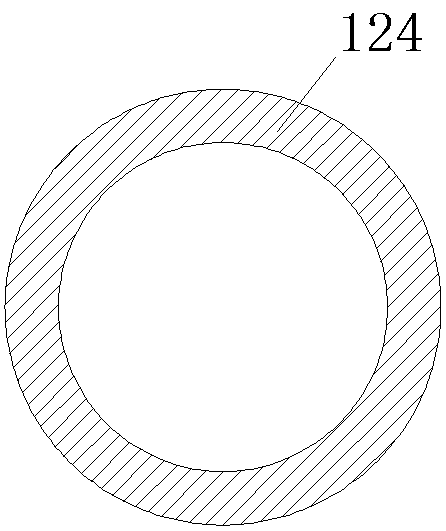

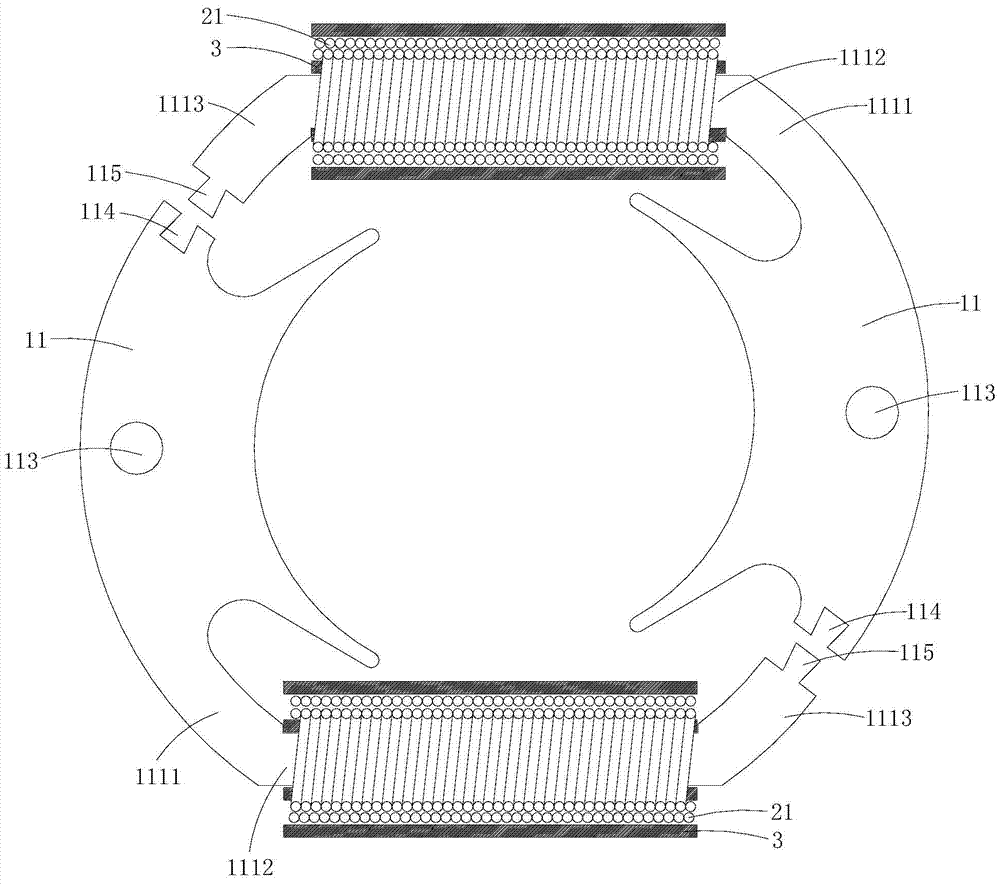

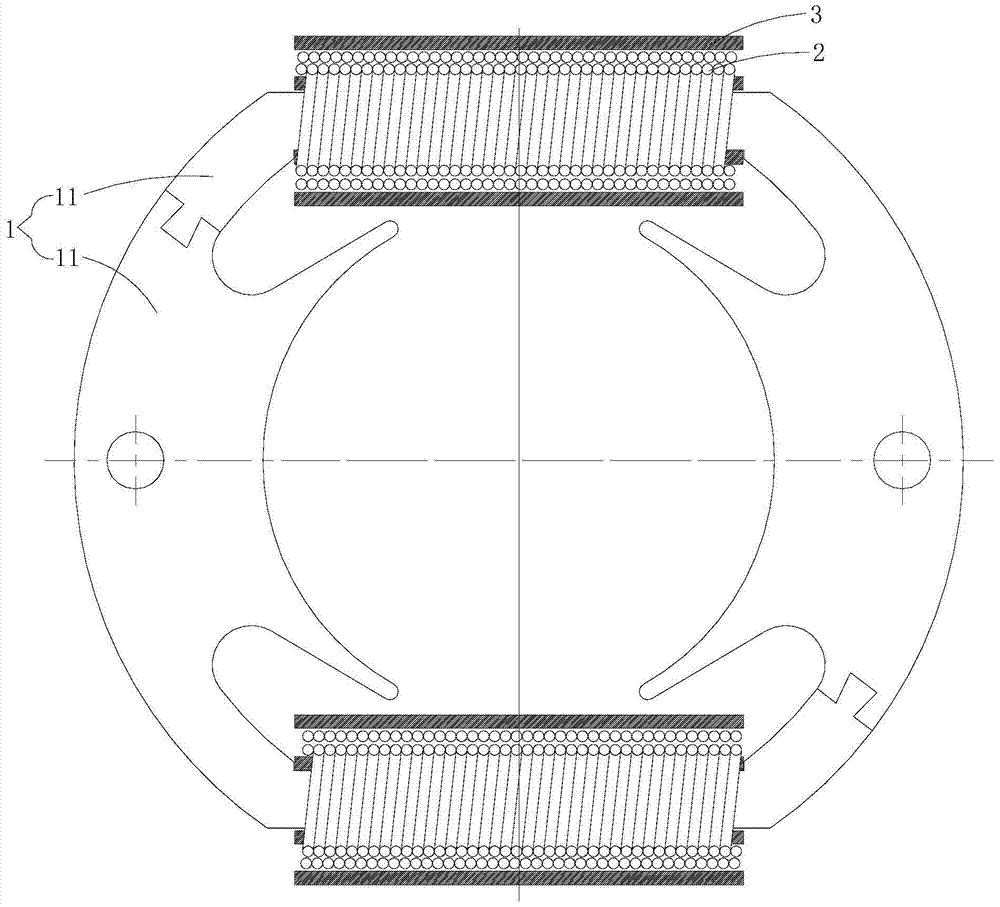

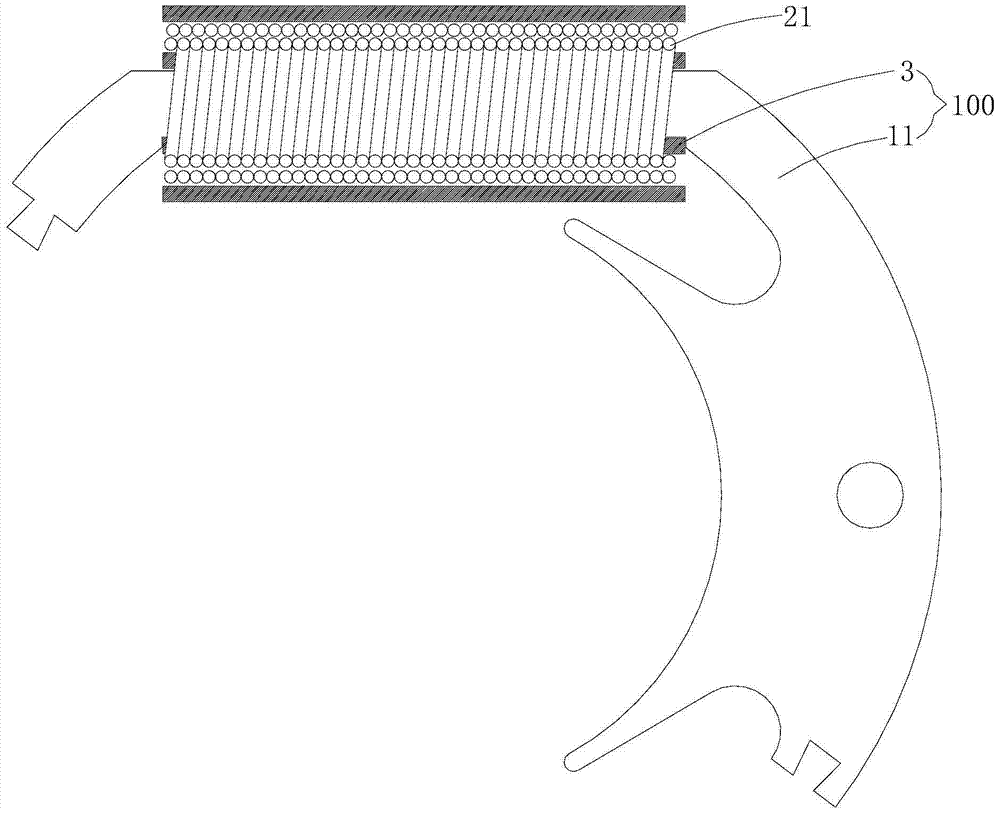

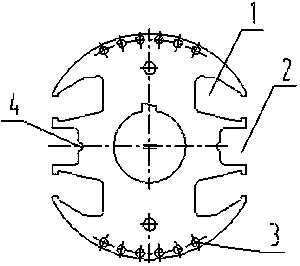

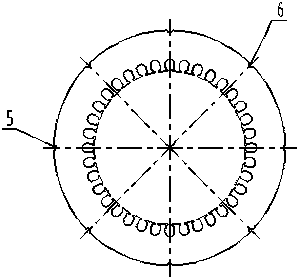

Series motor, stator iron core and stator thereof, and manufacturing method of stator

ActiveCN105024464AIncrease productivityReduce sizeWindings insulation shape/form/constructionMagnetic circuit stationary partsConductor CoilPhysics

The invention is suitable for the field of motors and provides a series motor stator iron core, a series motor stator, a manufacturing method of the series motor stator, and a series motor, wherein two iron core parts are spliced along the circumferential direction along the series motor stator iron core, each iron core part comprises a sub stator yoke and a stator tooth arranged on the sub stator yoke in a projected manner. The sub stator yoke comprises a first arc-shaped yoke part, a straight yoke part whose one end is connected with one end of the first arc-shaped yoke part, and a second arc-shaped yoke part whose one end is connected with the other end of the straight yoke part. The stator tooth is arranged on the first arc-shaped yoke part in a projected manner. The first arc-shaped yoke part and the second arc-shaped yoke part of one iron core part are respectively connected with the second arc-shaped yoke part and the first arc-shaped yoke part of the other iron core part. According to the invention, the winding efficiency of a stator winding is improved; sizes of end parts, projected from two ends of the stator iron core along the axial direction of the stator iron core, of the stator winding are reduced; the coil perimeter of the stator winding is reduced, the utilization rate of the stator winding is improved, and the cost of the series motor is lowered.

Owner:FOSHAN WEILING WASHER MOTOR MFG

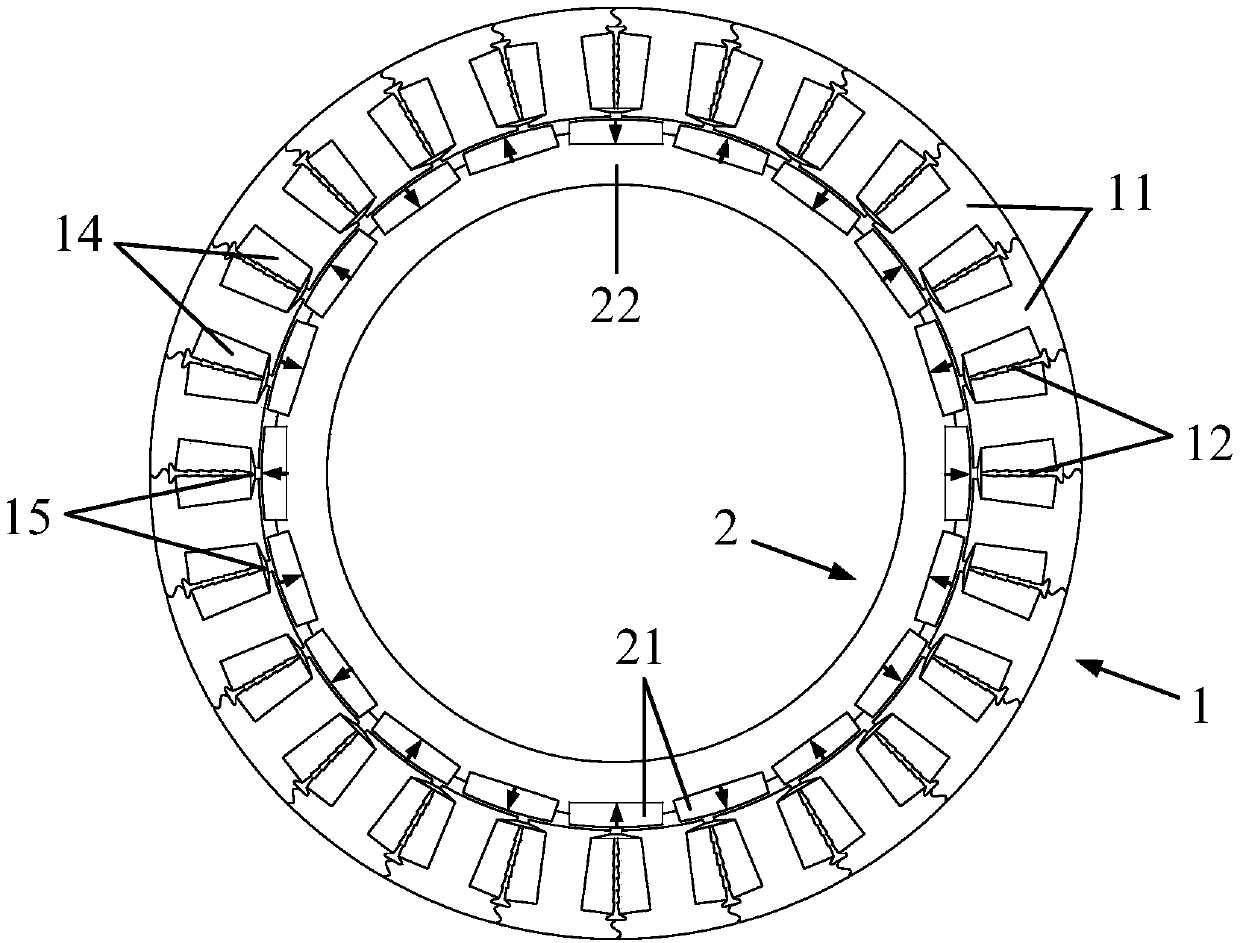

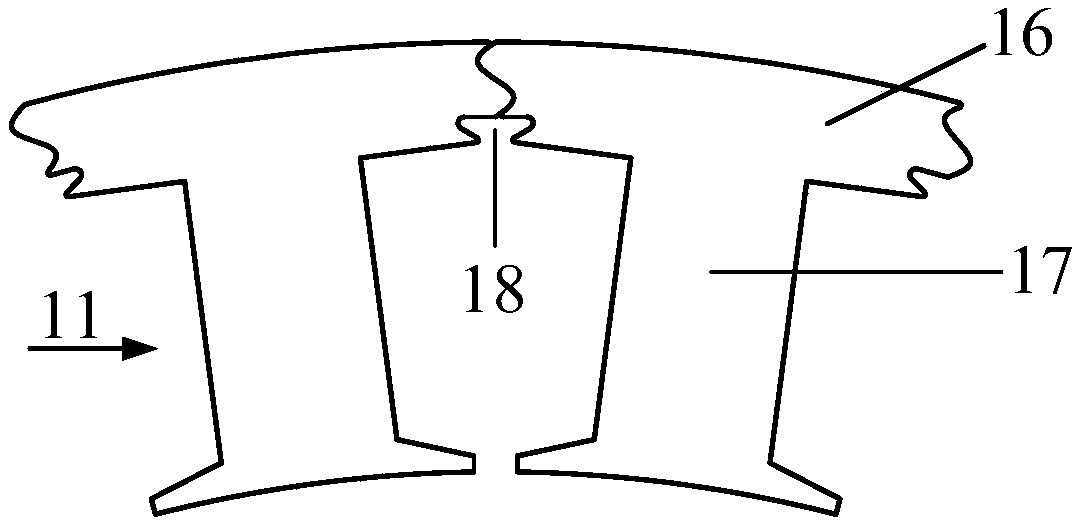

Novel permanent magnet motor with high reliability and high power density

InactiveCN109599958AImprove fault toleranceIncrease phase independenceMagnetic circuit stationary partsCooling/ventillation arrangementFilling ratePerformance index

The invention discloses a novel permanent magnet motor with high reliability and high power density. A stator adopts a modular structure, an isolated strip-shaped structure is designed at the center of a groove to match a modular main stator core, and a winding adopts a fractional slot concentrated winding structure having a span of 1. A rotor can adopt a conventional surface patching structure, ahighly polymagnetic Hallbach permanent magnet array structure or a built-in permanent magnet structure. The novel permanent magnet motor has the advantages of greatly improving the winding process bymeans of the matching of the modular stator structure, the isolated strip-shaped structure and a cross section shape of a conducting wire, thereby improving the slot filling rate of the motor from the processing technology. In addition, through the thermal conduction and magnetic isolation functions of the isolated strip-shaped structure, the performance indexes such as the electromagnetic torqueand the amount of permanent magnets and the like of the motor are basically not affected while reducing the motor winding temperature and improving the interphase independence of the winding.

Owner:JIANGSU UNIV

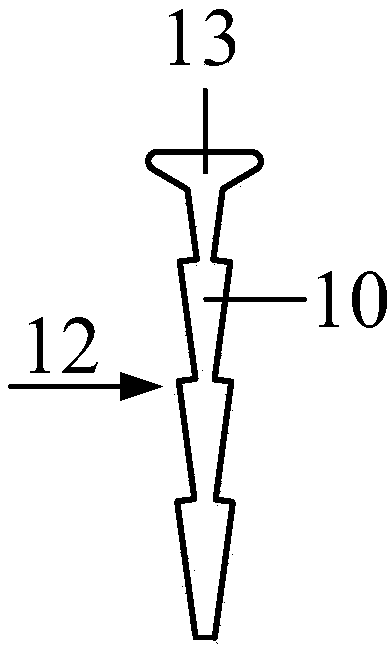

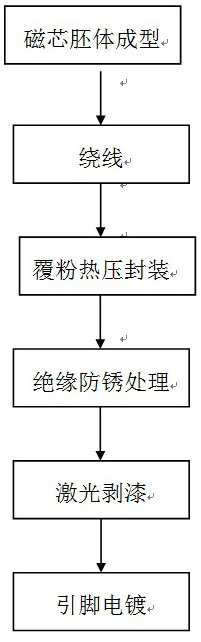

Integrated segmented forming micro-inductor manufacturing process

PendingCN112542305AImprove winding yieldReduced risk of short circuitsEncapsulation/impregnationCoils manufactureMagnetic coreBatch production

The invention discloses an integrated segmented forming micro-inductor manufacturing process which comprises the steps of magnetic core blank forming, winding, powder-coated hot-pressing packaging, insulating rust-proof treatment, laser paint stripping and pin electroplating. A semi-finished inductor is obtained by winding a flat wire on a magnetic core, and the winding inductor is provided with acomplete closed magnetic loop; and the conductor is only provided with a complete coil, and an integrated hot press molding process is adopted, so that the inductor product has the advantages of highsaturation current, high current resistance and low noise. The insulating rust-proof treatment process adopts a thermal spraying technology, so that the inductor meets the requirements of insulationand rust prevention, and meanwhile, the salt fog resistance of the inductor is improved. The design of directly stripping the resin layer on the inductor by laser to obtain the pins is adopted, silverpaste does not need to be printed, connection such as metal guide piece welding is not adopted, the structure is more stable, the overall process is simpler, and automatic large-batch production is easy.

Owner:华萃微感电子(江苏)有限公司

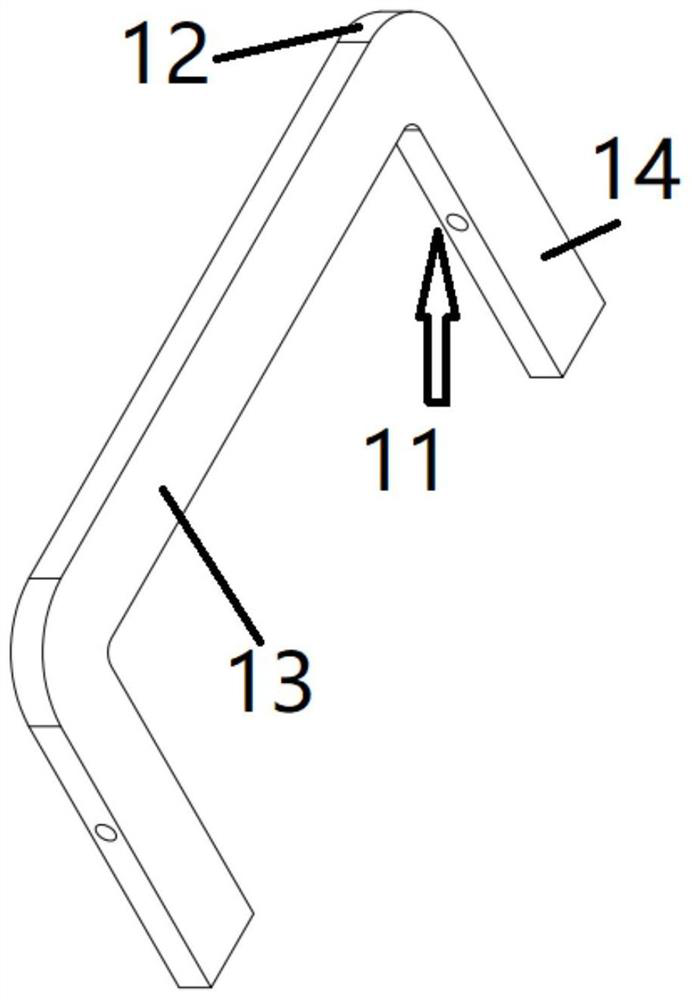

Winding process of stator interphase coil

ActiveCN104868665AImprove winding processControl lengthManufacturing dynamo-electric machinesElectric machineStator coil

The invention, which belongs to the production technology of the motor stator, especially relates to a process for stator interphase coil winding. On the basis of cladding and clamping of an enameled wire by a feeding and cutting mechanism and pre rotation of a winding nozzle, problems of long length of the stator interphase bridging wire and unstable shape can be solved; and thus the length of the bridging wire is reduced and the shapes of the bridging wires are uniform. Therefore, the forming quality of the stator interphase bridging wire is improved and the length of the bridging wire is shortened.

Owner:CHANGZHOU JINKANG PRECISION MECHANISM

Convenient type textile winding machine

InactiveCN107673119AImprove running stabilityIncrease winding speedFilament handlingWinding machineBobbin

The invention discloses a portable textile winding machine, which comprises a winding frame body composed of a first frame body and a second frame body. A cavity extending left and right is arranged in the first frame body, and a cavity on the right side of the cavity The inner front wall is provided with a first sliding groove, the first sliding groove is provided with a rear side extending into the cavity and slidingly fitted to connect the sliding block, a hinge is provided on the left end surface of the sliding block in the cavity, and the hinge is hinged There is a hinged push rod extending to the left side, the left end of the hinged push rod is provided with a hinge sleeve, and the inner sleeve of the hinge sleeve is provided with a U-shaped hinge rod. The rear end of the U-shaped articulated rod is connected with the winding motor, the outer surface of the winding motor is embedded in the rear inner wall of the cavity and fixedly connected, and the left end surface of the second frame body is provided with a second sliding groove extending forward and backward. A moving block is arranged in the second sliding groove; the invention has a simple structure, can realize fast installation and disassembly, improves the replacement speed of the wire barrel, and can evenly wind the wire.

Owner:CIXI QICHENG MACHINERY TECH CO LTD

Convenient and rapid type textile winding mechanism

ActiveCN107215710AUniform winding workAvoid affecting the processing processFilament handlingEngineeringMechanical engineering

The invention discloses a convenient and rapid type textile winding mechanism which comprises a winding frame body composed of a first frame main body and a second frame main body. The first frame main body is internally provided with a cavity arranged in a left-right extension mode; a first sliding groove is formed in the inner front wall of the right side of the cavity; a sliding block is arranged in the first sliding groove, wherein the rear side of the sliding block extends into the cavity, and the sliding block is slidably connected with the first sliding groove in a matched mode; a hinging piece is arranged on the end face of the left side of the sliding block in the cavity; a hinging pushing rod extending towards the left side is hinged into the hinging piece; a hinging sleeve is arranged at the tail end of the left side of the hinging pushing rod; a U-shaped hinging rod is sleeved with the hinging sleeve; the front side end of the U-shaped hinging rod is rotatably connected with the inner wall of the front side of the cavity in a matched mode; the rear side end of the U-shaped hinging rod is connected with a winding motor in a matched mode; the outer surface of the winding motor is embedded in the inner wall of the rear side of the cavity and is fixedly connected with the inner wall of the rear side of the cavity; a second sliding groove arranged in a front-rear extension mode is formed in the end face of the left side of the second frame main body; and a moving block is arranged in the second frame main body. The structure is simple, quick mounting and dismounting can be realized, the replacing speed of a thread cylinder is increased, and winding work can be evened.

Owner:河北澜浩羊绒制品有限公司

Automatic textile winding device

ActiveCN107324133ARealize automatic transmission controlSpeed up the processFilament handlingEngineeringTextile

The invention discloses an automatic textile winding device comprising a winding device body which is composed of a first device main body and a second device main body fixed to the right side of the first main body. A first sliding groove is formed in the end face of the top of the right side of the first device main body, and a first sinking groove is formed in the position, in the first sliding groove, of the end face of the left side of the second device main body and connected with a first tooth-shaped wheel in a rotatably-matched mode. The top of the first tooth-shaped wheel is in matched connection with a first motor, and a second sliding groove extending in the longitudinal direction is formed in the position, on the right side of the first sinking groove, of the interior of the second device main body. A third sliding groove is formed in the inner wall of the right side of the second sliding groove and internally provided with a first threaded rod extending in the longitudinal direction, the top of the first threaded rod is in matched connection with a second motor, and a penetration hole extending towards the left side and the right side is formed in the position, below the first sinking groove, of the interior of the second device main body. According to the automatic textile winding device, the structure is simple, operation is convenient, and the effect that a winding cylinder is automatically mounted and locked to be prevented from falling off can be achieved, so that the mounting stability is improved; and automatic extending-in and extending-out of a sliding structure can be achieved, so that quick dismounting and mounting are facilitated, and the replacing speed of the winding cylinder is increased.

Owner:嘉兴市华益股份有限公司

Multi-phase permanent magnet fault-tolerant servo motor

InactiveCN111030329AIncrease electromagnetic loadImprove winding processMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machinePermanent magnet motor

The invention relates to the technical field of permanent magnet motors, and discloses a multi-phase permanent magnet fault-tolerant servo motor. The motor comprises a modular stator, a special-shapedarray coreless rotor and a casing. The outer circle surface of the modular stator is fixed on the inner circle surface of the casing. The special-shaped array coreless rotor is arranged in the modular stator, a preset air gap is formed between the special-shaped array coreless rotor and the modular stator, the modular stator is provided with Q grooves used for arranging Q stator submodules, and Qis an even number; the special-shaped array coreless rotor comprises a rotating shaft and p-pole permanent magnets, each pole permanent magnet is of a structure of a plurality of special-shaped arraymagnetizing permanent magnets, the p-pole permanent magnets are connected with the rotating shaft in a dovetail groove mode, and p is a positive integer. Therefore, the problems of low reliability, no fault-tolerant capability, slow dynamic response, low power density and the like of a conventional servo motor can be solved.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

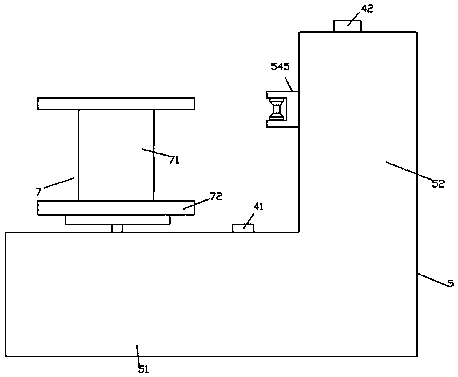

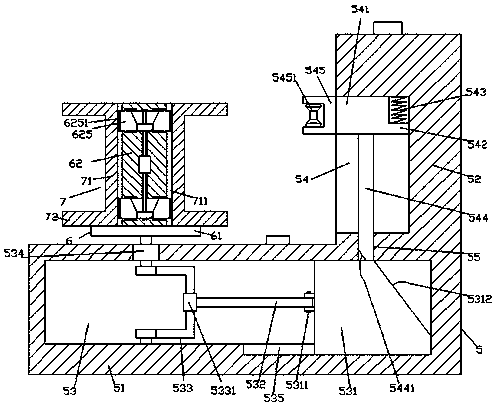

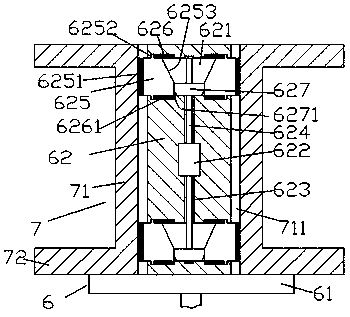

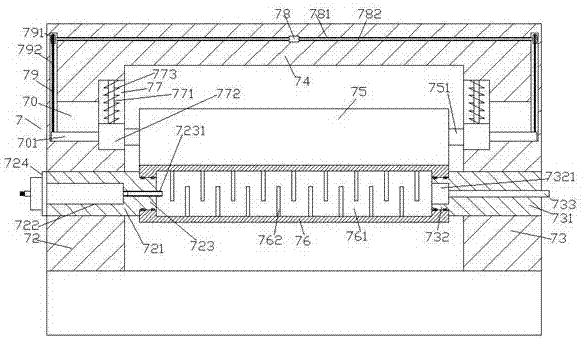

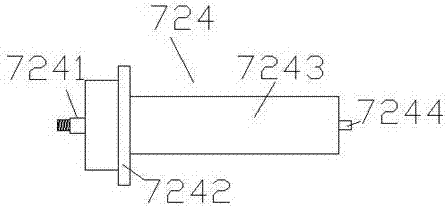

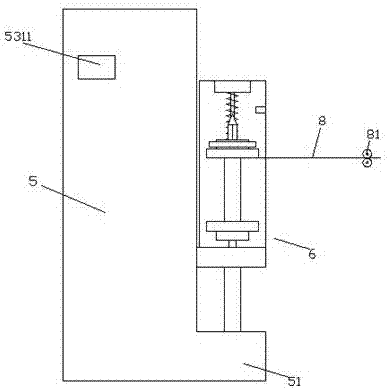

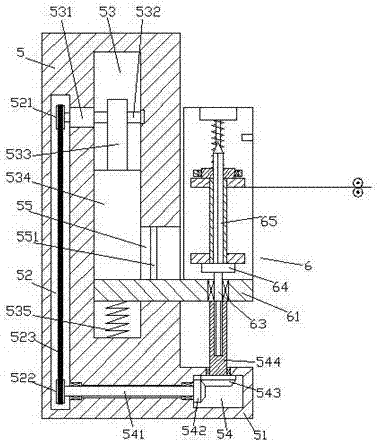

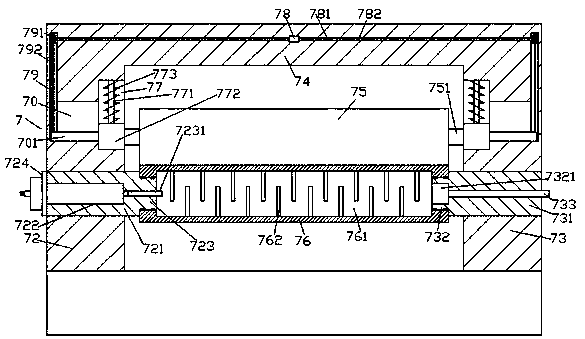

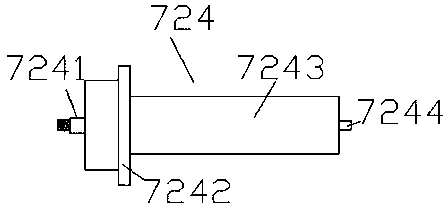

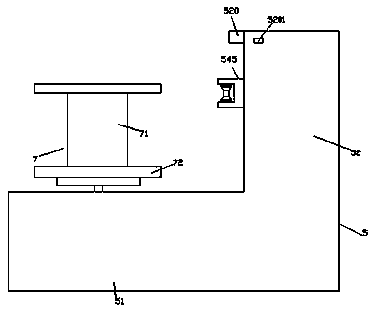

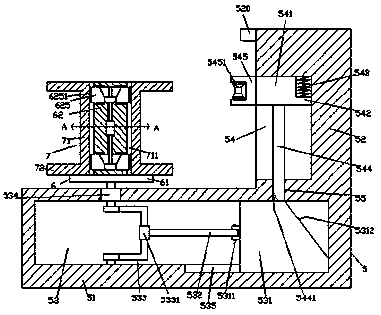

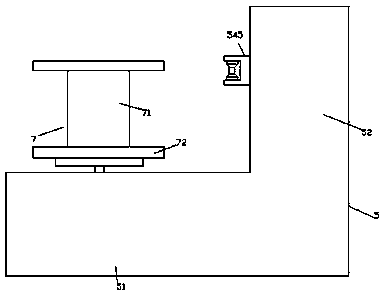

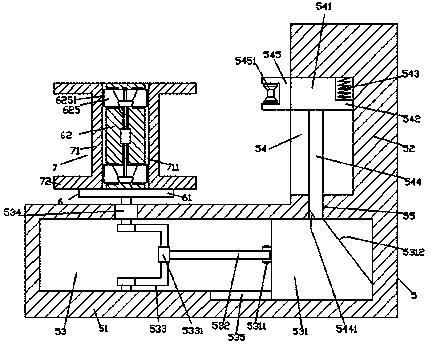

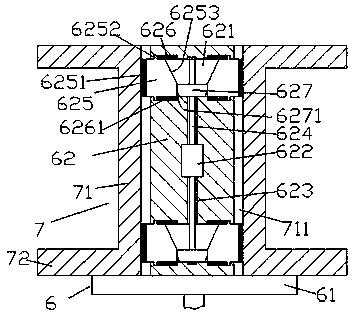

Medical disinfection equipment

ActiveCN107261160AImprove thermal conductivityFast heat conductionLavatory sanitoryHeatBed sheetsConductor Coil

The invention discloses medical disinfection equipment, which comprises a support, a heat sterilization device and a winding device, the heat sterilization device and the winding device are fixedly arranged at the front side and the rear side of the top surface of the support, the heat sterilization device comprises a first pillar and a second pillar which are arranged oppositely respectively at the left side and the right side, a connection pillar is fixedly arranged between the top surface of the first pillar and the top surface of the second pillar, the first pillar is internally fixedly provided with a first joint part, the second pillar is internally fixedly provided with a second joint part, the opposite sides of the first joint part and the second joint part are respectively provided with a first bulge and a second bulge, a first cylinder shaft is arranged between the first joint part and the second joint part, the first cylinder shaft is internally provided with an inner cavity, a plurality of up-down staggered iron sheets are arranged inside the inner cavity; the medical disinfection equipment has the advantages of simple structure, quick installation can be realized when in winding, the clean level of bed sheets can be improved, the spring coil can realize automatic tension, at the same time, the disinfection effect is improved.

Owner:连云港康力特药业有限公司

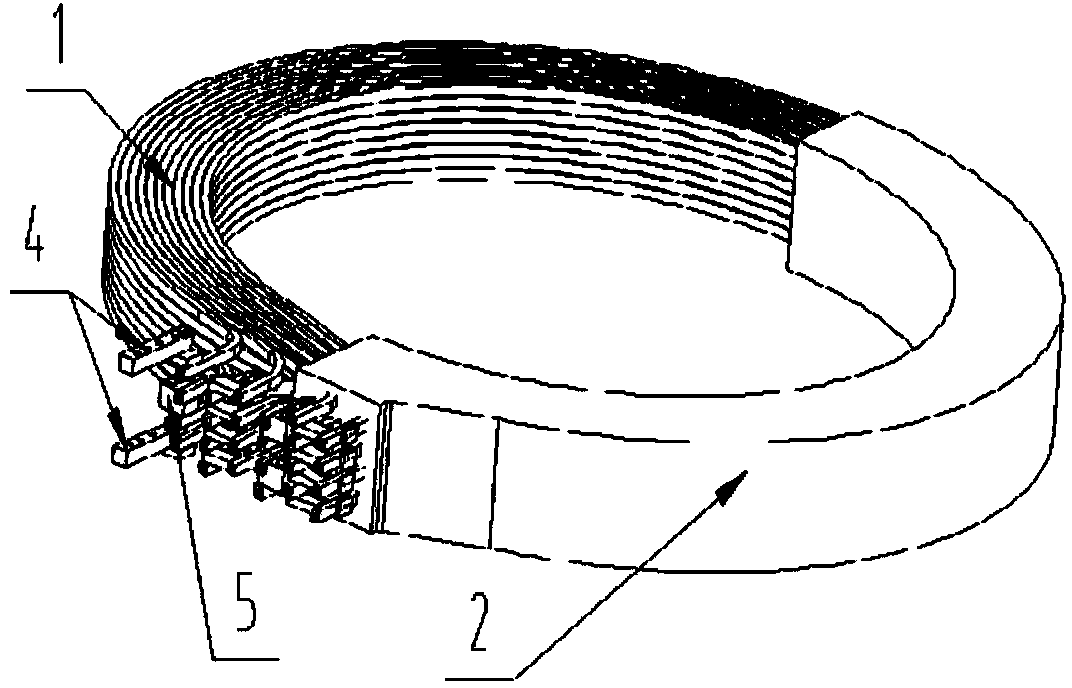

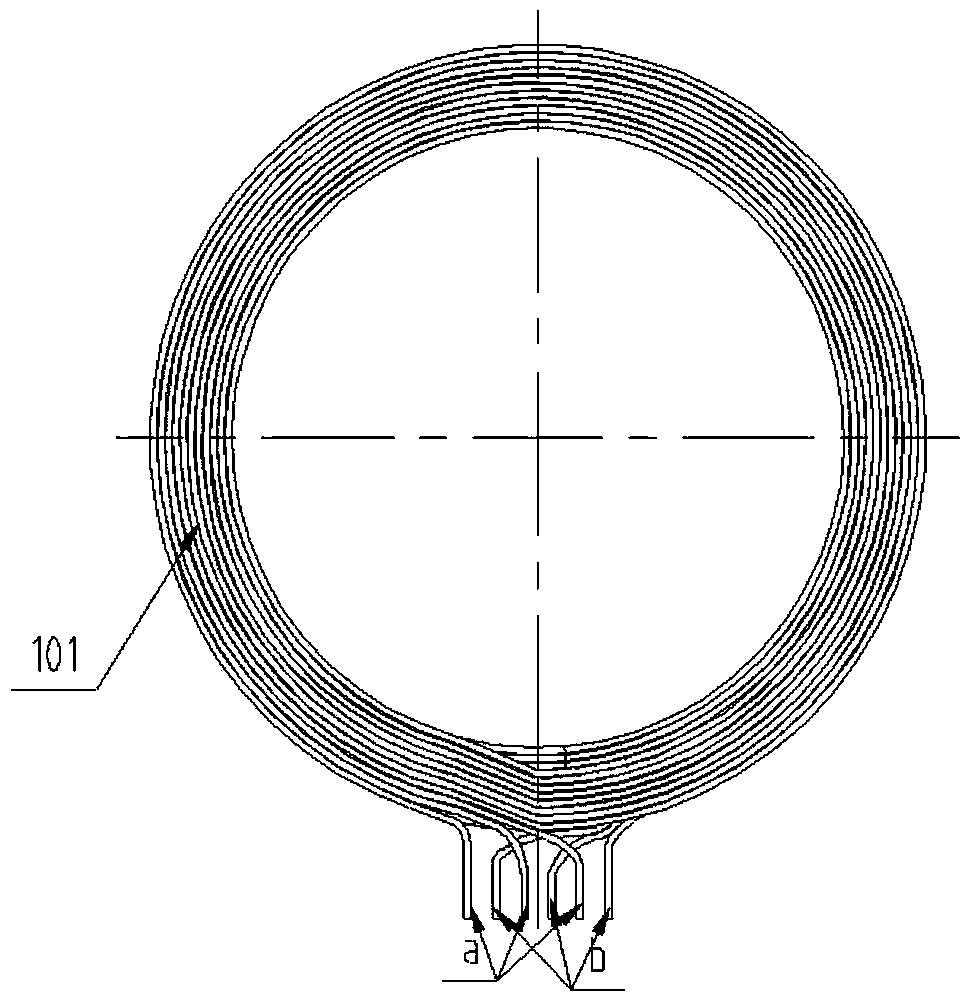

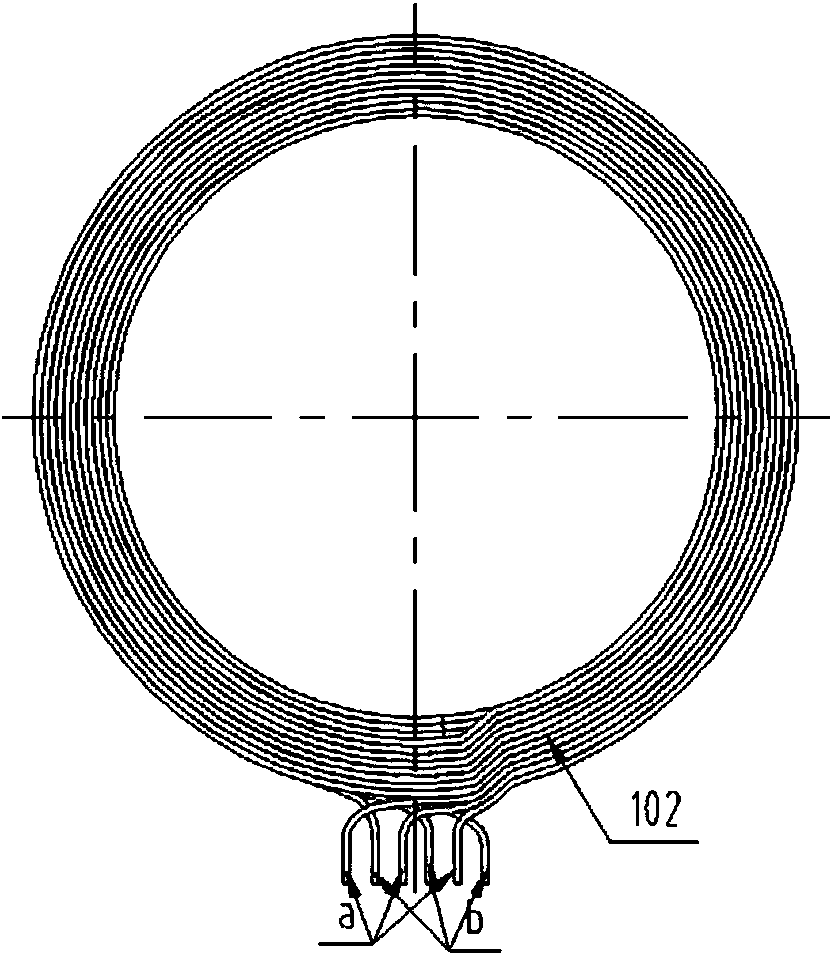

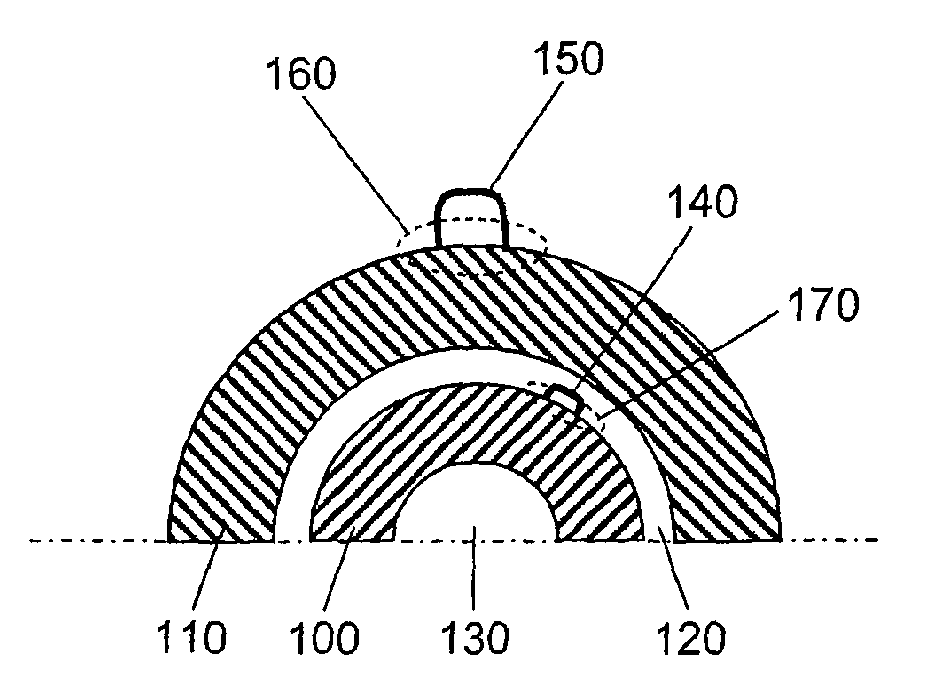

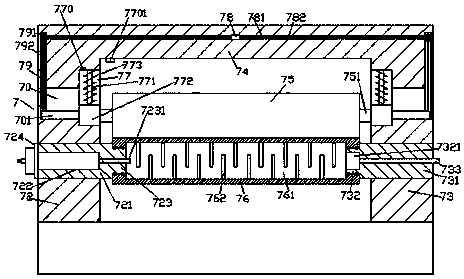

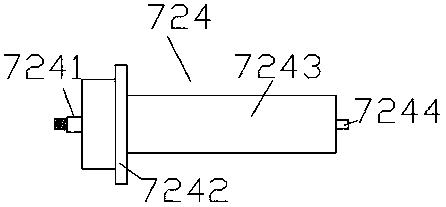

CUSP magnetic field generator coil and processing method thereof

ActiveCN103887034AThe manufacturing process is arranged reasonablyHigh yield in industrialized productionPolycrystalline material growthCoils manufactureEpoxyManufacturing technology

The invention relates to nonmetal crystal manufacturing equipment, and aims to provide a CUSP magnetic field generator coil and a processing method thereof. The CUSP magnetic field generator coil comprises a cylindrical coil assembly wound by copper tubes, a water inlet and outlet end, epoxy resin, insulating plates, electrodes and connectors are arranged on one side of the coil assembly, the insulating plates are arranged between the copper tubes, and the epoxy resin covers the integral coil assembly in a casting manner; the connectors and the electrodes are arranged at the water inlet and outlet end of the coil assembly. The CUSP magnetic field generator coil has the advantages that the coil manufacturing technology is reasonable in arrangement, and industrialized production yield is high; the coil is wound by the optimized copper tubes and integrally cast by the epoxy resin and is good in thermal stability; by parallel winding coil units via multiple copper tubes, waterway distance of a single copper tube is shortened, and temperature rise of the coil is low; the winding requirement of the coil that any radial turns and axial turns are the multiple of four can be met, and more flexible options are provided for optimized design of the coil.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL +1

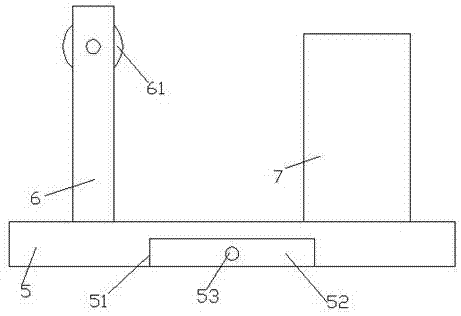

Wire wrapping device for spinning

The invention discloses a wire wrapping device for spinning. The wire wrapping device comprises a machine body and guide transmission wheels which are arranged at the right side of the machine body and are symmetrically arranged up and down, wherein a lug boss part is arranged on the bottom of the end surface at the right side of the machine body; a wire wrapping mechanism is arranged above the lug boss part; the wire wrapping mechanism comprises a bottom plate which extends left and right, a connecting block which is fixedly arranged at the rear side of the right side of the bottom plate, a straight plate which is fixedly arranged at the rear side end of the connecting block and extends upwards, and a wire wrapping base arranged above the bottom plate; the bottom of the wire wrapping base is fixedly equipped with a first rotary shaft; the bottom of the first rotary shaft penetrates through the bottom plate and is rotatably connected with the bottom plate in a matched mode; the bottom of the first rotary shaft is fixedly equipped with an outer spline shaft which extends downwards; a single spline shaft is fixedly arranged on the top of the wire wrapping base; a first transmission cavity is arranged in the lug boss part; and an inner spline rotary shaft which extends towards upper and lower sides is rotatably matched and connected in the top wall in the first transmission cavity. The wire wrapping device is simple in structure, realizes automatically controlling upper and lower movable wire wrapping work, improves wire wrapping uniformity, realizes quickly dismounting a bobbin and improves wire wrapping stability.

Owner:惠州市骏鹏织造有限公司

Automatic type textile winding device

InactiveCN107934679AEasy to install and removeImprove overall winding processFilament handlingWinding machineEngineering

The invention discloses an automatic type textile winding device. The device comprises a winding machine body composed of a first machine body and a second machine body fixed on the right side of thefirst machine body; a first sliding groove is formed in the top end surface of the right side of the first machine body, a first sinking groove is formed in the left end surface of the portion, in thefirst sliding groove, of the second machine body, the first sinking groove is rotationally connected with a first tooth-shaped wheel in a matched mode, and the top of the first tooth-shaped wheel isconnected with a first motor in a matched mode; a second sliding groove which extends longitudinally is formed in the portion, on the right side of the first sinking groove, of the second machine body, and a third sliding groove is formed in the inner wall of the right side of the second sliding groove; a first threaded rod which extends longitudinally is arranged in the third sliding groove, andthe top of the first threaded rod is connected with a second motor in a matched mode; and a penetrating hole which extends to the left side and the right side are formed in the portion, below the first sinking groove, of the second machine body. According to the device, the structure is simple, the operation is convenient, a winding drum can be automatically installed and locked so that the winding drum can be prevented from falling off, then the installation stability can be improved, a sliding structure can automatically extend in and out so that quick dismounting and mounting can be facilitated, and the replacement speed of the winding drum can be increased.

Owner:CIXI KUANGYAN YINGYING BAMBOO PROD FACTORY GENERAL PARTNERSHIP

Convenient textile winding mechanism

InactiveCN107673121AImprove running stabilityIncrease winding speedFilament handlingBobbinEngineering

The invention discloses a convenient textile winding mechanism, which comprises a winding frame body composed of a first frame body and a second frame body. A cavity extending left and right is arranged in the first frame body, and the inner cavity on the right side of the cavity The front wall is provided with a first sliding groove, the first sliding groove is provided with a rear side extending into the cavity and slidingly fitted to connect the sliding block, a hinge is arranged on the left end surface of the sliding block in the cavity, and a hinge is hinged in the hinge. The hinged push rod extending to the left is provided with a hinged sleeve at the left end of the hinged push rod, and a U-shaped hinged rod is arranged inside the hinged sleeve. The rear side end of the type hinged rod is connected with the winding motor, the outer surface of the winding motor is embedded in the inner wall of the rear side of the cavity and is fixedly connected, and the second sliding groove extending forward and backward is provided in the left end surface of the second frame body. The second sliding groove is provided with a moving block; the invention has a simple structure, can realize fast installation and disassembly, improves the replacement speed of the wire barrel, and can evenly wind the wire.

Owner:CIXI QICHENG MACHINERY TECH CO LTD

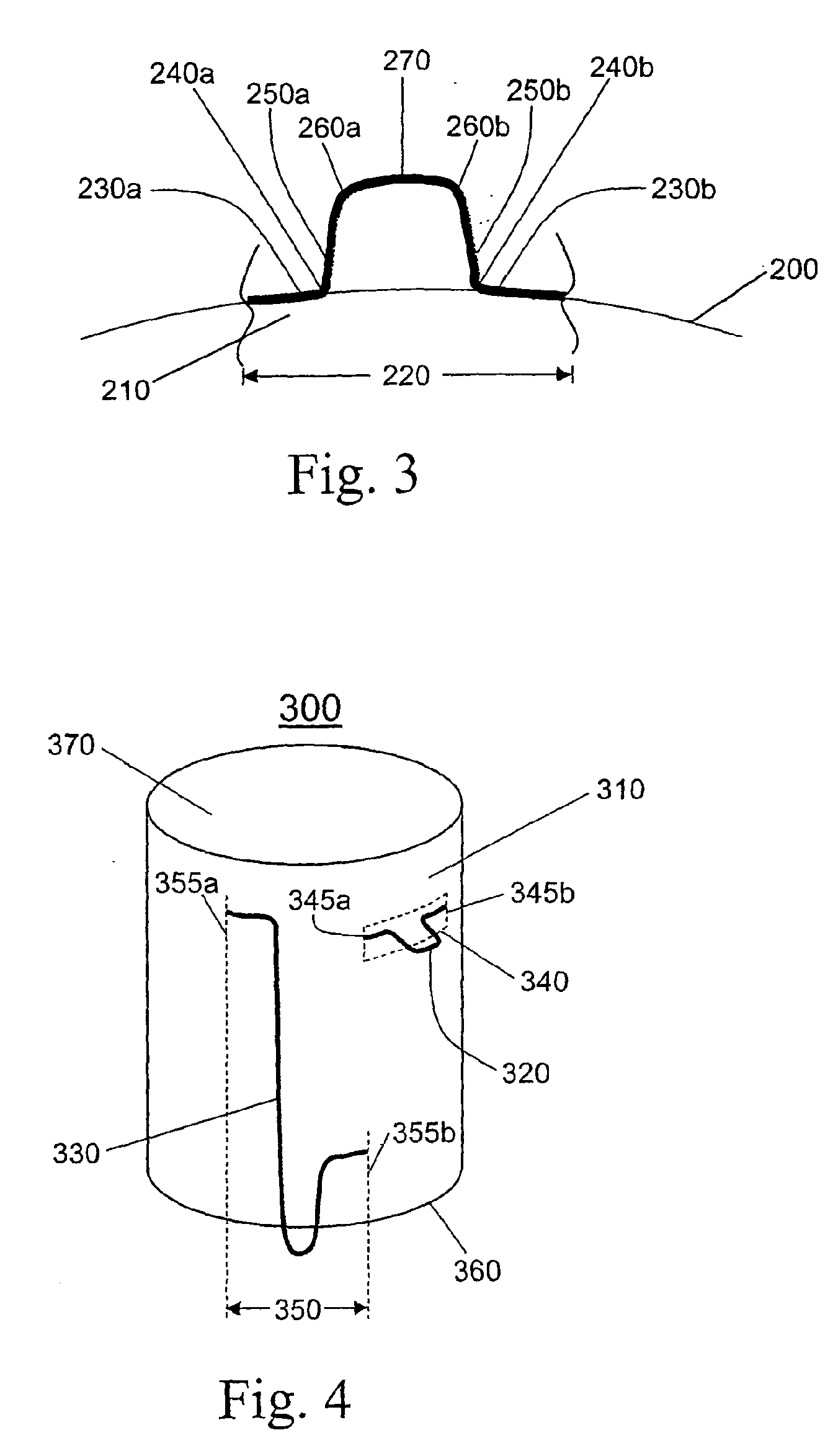

Electric component with winding and tapping

InactiveUS20100134232A1Better mechanismImprove winding processContact member assembly/disassemblyTransformers/inductances coils/windings/connectionsElectrical conductorTransformer

A power transformer includes at least one winding formed from at least one conductor extending along a circumferential direction, wherein the at least one winding has a tap in a contact section formed by a profile of the at least one conductor in at least one direction inclined relative to the circumferential direction; and at least one supporting element configured to support the conductor in the contact section.

Owner:ABB TECH AG

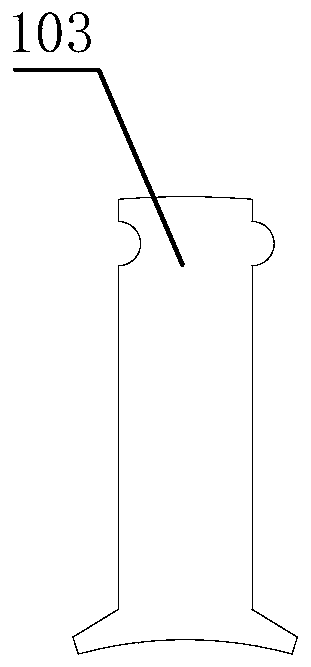

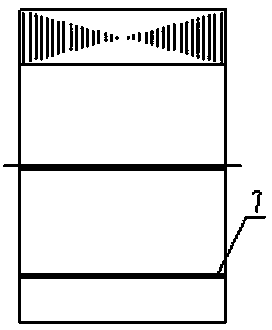

Secondary framework of 100KVA high-voltage pulse transformer

PendingCN111627680ASimple processingSimple winding processTransformers/inductances coils/windings/connectionsPhysicsVoltage pulse

Owner:XIANGYANG JIUDING HAOTIAN ENVIRONMENTAL PROTECTION EQUIP

Spinning wire winding device

InactiveCN108002134AWork fasterRealize the installation workFilament handlingAutomatic controlBobbin

The invention discloses a spinning wire winding device. The spinning wire winding device comprises a machine body, and guide wheels arranged on the right side of the machine body and symmetrically arranged in an up-and-down mode; a boss part is arranged at the bottom of the right side end surface of the machine body; a wire winding mechanism is arranged above the boss part; the wire winding mechanism comprises a baseplate extending left and right, a connecting block fixed on the back side of the right side of the baseplate, a straight plate fixed at the back side end of the connecting block and upwards extending, and a wire winding base arranged above the baseplate; a first rotating shaft is fixedly arranged at the bottom of the wire winding base; the bottom of the first rotating shaft penetrates through the baseplate for rotary cooperating connection; an outer spline shaft downwards extending is fixedly arranged at the bottom of the first rotating shaft; a single key shaft is fixedlyarranged at the top of the wire winding base; a first transmission cavity is formed in the boss part; and an inner spline rotating shaft extending to the upper and lower sides is in rotary cooperatingconnection into the inner top wall of the first transmission cavity. The spinning wire winding device is simple in structure, realizes automatic control of up-down movable wire winding work, improvesthe wire winding uniformity, realizes quick disassembly of bobbins, and improves the wire winding stability.

Owner:扬州市青山环保科技有限公司

Anti-knotting spinning wire winding device

InactiveCN108002125AWork fasterRealize the installation workFilament handlingBobbinAutomatic control

The invention discloses an anti-knotting spinning wire winding device. The anti-knotting spinning wire winding device comprises a machine body, and guide wheels arranged on the right side of the machine body and symmetrically arranged up and down; a boss part is arranged at the bottom of the right side end surface of the machine body; a wire winding mechanism is arranged above the boss part; the wire winding mechanism comprises a baseplate extending left and right, a connecting block fixed on the back side of the right side of the baseplate, a straight plate fixed at the back side end of the connecting block and upwards extending, and a wire winding base arranged above the baseplate; a first rotating shaft is fixedly arranged at the bottom of the wire winding base; the bottom of the firstrotating shaft penetrates through the baseplate for rotary cooperating connection; an outer spline shaft downwards extending is fixedly arranged at the bottom of the first rotating shaft; a single keyshaft is fixedly arranged at the top of the wire winding base; a first transmission cavity is formed in the boss part; and an inner spline rotating shaft extending to the upper and lower sides is inrotary cooperating connection into the inner top wall of the first transmission cavity. The anti-knotting spinning wire winding device is simple in structure, realizes automatic control of up-down movable wire winding work, improves the wire winding uniformity, realizes quick disassembly of bobbins, and improves the wire winding stability.

Owner:CIXI QICHENG MACHINERY TECH CO LTD

A medical disinfection device

ActiveCN107261160BImprove thermal conductivityFast heat conductionLavatory sanitoryHeatConductor CoilMechanical engineering

Owner:连云港康力特药业有限公司

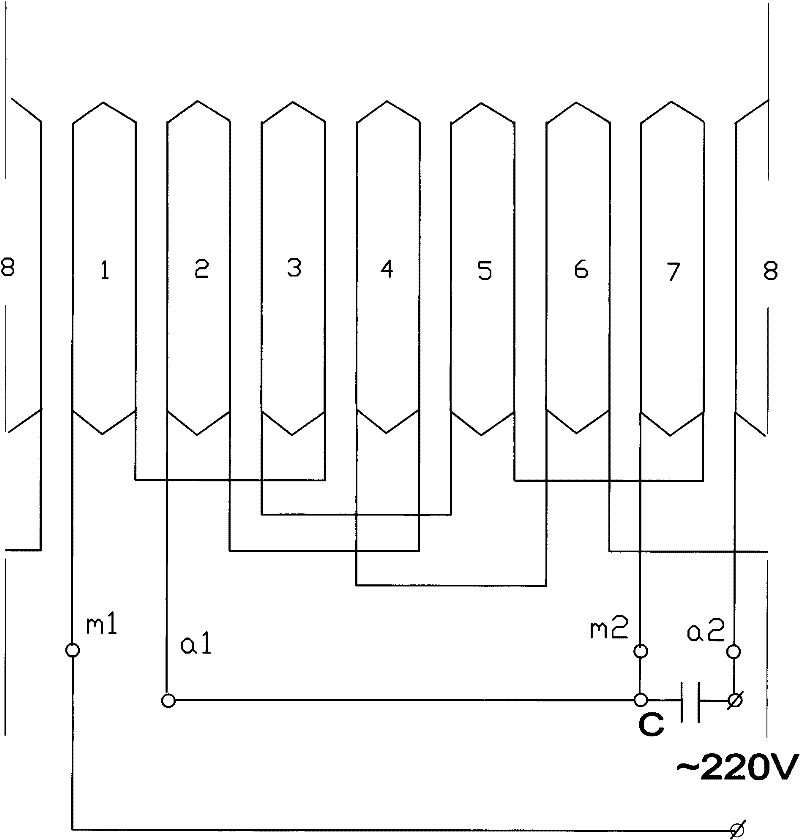

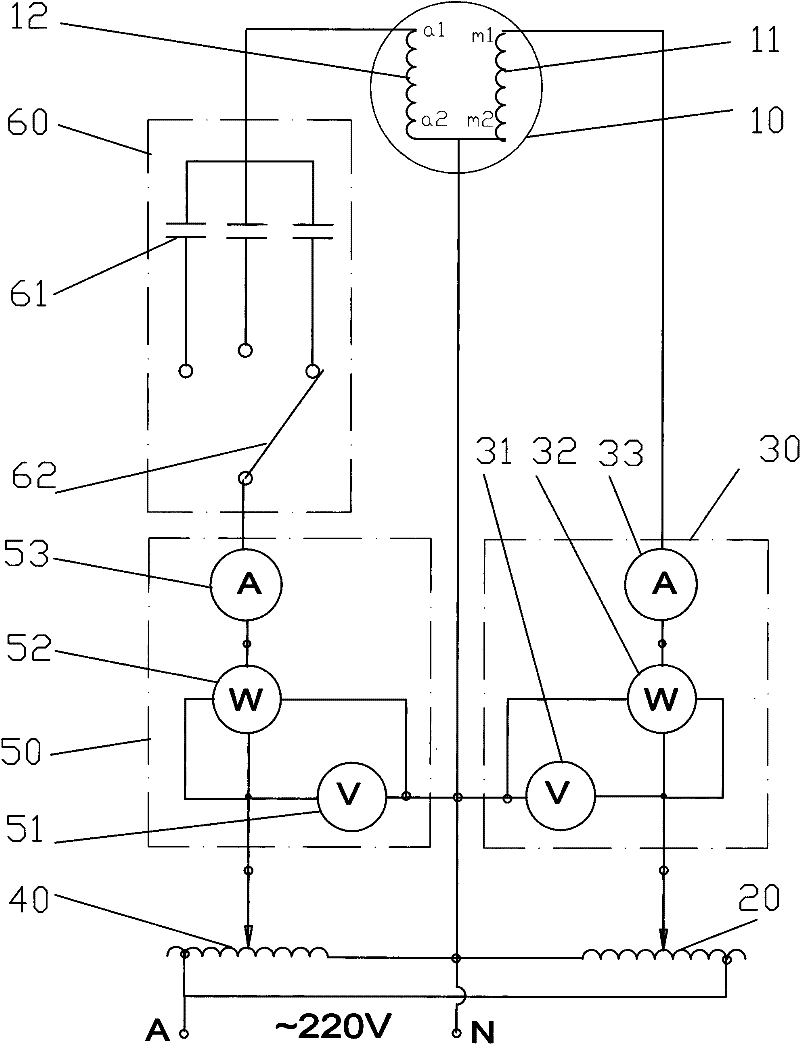

Low-power single-phase condenser motor and method for adjusting capacitance and turn number thereof

InactiveCN102332798AImprove performanceImprove winding processAsynchronous induction motorsWindings conductor shape/form/constructionCapacitanceOperating point

The invention relates to a low-power single-phase condenser motor, which comprises a stator core, a main phase winding, a sub-phase winding and a condenser, wherein the space electrical angle difference between the main phase winding and the sub-phase winding which are arranged on the stator core is 90 degrees; and the sub-phase winding is connected with the condenser in parallel and then is connected with the main phase winding in series to be connected to a power supply. A method for adjusting capacitance and turn number of the motor comprises the following steps: 1) wire embedding is carried out on the stator core, a rotor is used for manufacturing a two-phase winding motor prototype, the space electrical angle difference of two-phase windings which are arranged on the stator core is 90 degrees, the motor is operated symmetrically at a rated operating point, the effective turn number of the one-phase winding is Wm, the voltage of the connected power supply is Um, and the conductance g and the electrical susceptance b of the phase loop at the time are measured; and 2) the effective turn number Wm' of the main phase winding, the effective turn number Wa' of the sub-phase winding, and the capacitance C' are regulated to be as following formulas: Wm'=Wm*UN / (Um(1+(g / b)<2>)<0.5>); Wa'=Wm* (g / b)*UN / (Um(1+(g / b)<2>)<0.5>); C'=(b+b<3> / g<2>) / (2Pi*f*UN<2> / Um<2>(1+(g / b)<2>))); and in the formulas, the UN refers to the rated voltage of the motor, and the f refers to the rated frequency of the motor. Compared with the traditional technology, in the design, the winding process is improved, the computational workload is reduced, and better performance is achieved.

Owner:叶露微

Thread rolling machine for glass fiber production

InactiveCN109230833AAvoid breakingImprove the protective effectDomestic cooling apparatusLighting and heating apparatusGlass fiberDrive shaft

The invention relates to the technical field of glass production, and discloses a thread rolling machine for glass fiber production. The machine comprises a base placed on the earth surface and two support plates symmetrically installed on the front face of the base, a transmission shaft, a screw rod and a limiting rod are sleeved between the two support plates from bottom to top in sequence, thetransmission shaft and the screw rod are rotationally connected between the screw rod and the support plate through bearings, the screw rod and the support plates are fixedly connected, a driving device is arranged on one side of the front face of the base, and the middle section, located between the two support plates, of the transmission shaft is sleeved with a thread rolling roller. According to the thread rolling machine for glass fiber production, by arranging a port component, glass fiber filaments can be protected conveniently at one section getting in and out of a winding frame, the problem that the glass fiber filaments rub against edges of an inlet and an outlet of the winding frame to be broken is effectively avoided, the whole winding process is more reliable, and the winding technology of the glass fiber filaments is improved.

Owner:湖南湘潇玻璃纤维有限公司

Novel spinning wire winding device

InactiveCN108002127AWork fasterRealize the installation workFilament handlingBobbinAutomatic control

The invention discloses a novel spinning wire winding device. The novel spinning wire winding device comprises a machine body, and guide wheels arranged on the right side of the machine body and symmetrically arranged up and down; a boss part is arranged at the bottom of the right side end surface of the machine body; a wire winding mechanism is arranged above the boss part; the wire winding mechanism comprises a baseplate extending left and right, a connecting block fixed on the back side of the right side of the baseplate, a straight plate fixed at the back side end of the connecting block and upwards extending, and a wire winding base arranged above the baseplate; a first rotating shaft is fixedly arranged at the bottom of the wire winding base; the bottom of the first rotating shaft penetrates through the baseplate for rotary cooperating connection; an outer spline shaft downwards extending is fixedly arranged at the bottom of the first rotating shaft; a single key shaft is fixedlyarranged at the top of the wire winding base; a first transmission cavity is formed in the boss part; and an inner spline rotating shaft extending to the upper and lower sides is in rotary cooperating connection into the inner top wall of the first transmission cavity. The novel spinning wire winding device is simple in structure, realizes automatic control of up-down movable wire winding work, improves the wire winding uniformity, realizes quick disassembly of bobbins, and improves the wire winding stability.

Owner:CIXI QICHENG MACHINERY TECH CO LTD

Textile winding device

InactiveCN107934680ARealize automatic transmission controlSpeed up the processFilament handlingWinding machineConductor Coil

The invention discloses a textile winding device. The device comprises a winding machine body composed of a first machine body and a second machine body fixed on the right side of the first machine body; a first sliding groove is formed in the top end surface of the right side of the first machine body, a first sinking groove is formed in the left end surface of the portion, in the first sliding groove, of the second machine body, the first sinking groove is rotationally connected with a first tooth-shaped wheel in a matched mode, and the top of the first tooth-shaped wheel is connected with afirst motor in a matched mode; a second sliding groove which extends longitudinally is formed in the portion, on the right side of the first sinking groove, of the second machine body, and a third sliding groove is formed in the inner wall of the right side of the second sliding groove; a first threaded rod which extends longitudinally is arranged in the third sliding groove, and the top of the first threaded rod is connected with a second motor in a matched mode; and a penetrating hole which extends to the left side and the right side are formed in the portion, below the first sinking groove, of the second machine body. According to the device, the structure is simple, the operation is convenient, a winding drum can be automatically installed and locked so that the winding drum can be prevented from falling off, then the installation stability can be improved, a sliding structure can automatically extend in and out so that quick dismounting and mounting can be facilitated, and the replacement speed of the winding drum can be increased.

Owner:CIXI KUANGYAN YINGYING BAMBOO PROD FACTORY GENERAL PARTNERSHIP

Dust collector

ActiveCN107268254ARealize automatic controlQuick installationMechanical cleaningPressure cleaningAutomatic controlEngineering

The present invention discloses a dust collector. The dust collector comprises a base, winding devices respectively fixed at left and right sides of the top face of the base and a leading-in dust collector. Each winding device is formed by a first vertical frame and a second vertical frame which are opposite to each other front and back and fixedly arranged at the top face of the base, the opposite sides of the first vertical frame and the second vertical frame are provided with first sliding slots in an equivalence mode, each first sliding slot is internally provided with a first sliding block, a winding motor is fixedly arranged at the internal portion of the back side of the first vertical frame at the lower portion of the first sliding slot in the first vertical frame, the right side of the winding motor is matchingly connected with a first rotation and winding shaft, the second vertical frame opposite to the winding motor is internally provided with a sliding slot with a mode of run-through arrangement front and back, the inner bottom face of the sliding slot is provided with a guidance connection slot, and a second sliding block is in sliding matching connection with the internal portions of the sliding slot. The dust collector is simple in structure, the mounting and dismounting speed of a winding core is improved, the whole winding process is improved, the automatic control quantification winding work is realized, and the quality of fabrics is improved.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

a water conservancy device

The invention discloses a water conservancy device. The water conservancy device comprises a well rope winding rack; the well rope winding rack comprises a first rack and a second rack and is fixedly mounted beside a well; a hollow cavity extending leftwards and rightwards is formed in the first rack; a first sliding groove is formed in the right side of the hollow cavity; a sliding block connected in a sliding fit manner is arranged in the first sliding groove; a flexible connecting part is arranged on the left side surface of the sliding block in the hollow cavity; a push rod extending to the left side is flexibly connected in the flexible connecting part; a fixed sleeve is arranged at the tail of the left side of the push rod; a semi-circular rod piece is arranged in the fixed sleeve; the front side of the semi-circular rod piece is connected with the inner wall of the front side of the hollow cavity in a rotary fit manner; the back side of the semi-circular rod piece is connected with a well rope winding motor in a fit manner; the well rope winding motor is arranged in the inner wall of the back side of the hollow cavity and is fixedly connected with the inner wall; a second sliding groove extending forwards and backwards is formed in the left side surface of the second rack; and a second sliding block is arranged in the second sliding groove. The water conservancy device is simple in structure and can be mounted and dismounted quickly, the bobbin change speed can be increased, and the well rope winding work can be even.

Owner:WENLING QIHAO ELECTRONICS CO LTD

Series excitation motor and its stator core, stator and stator manufacturing method

ActiveCN105024464BIncrease productivityReduce sizeWindings insulation shape/form/constructionMagnetic circuit stationary partsElectric machineControl theory

The invention is suitable for the field of motors and provides a series motor stator iron core, a series motor stator, a manufacturing method of the series motor stator, and a series motor, wherein two iron core parts are spliced along the circumferential direction along the series motor stator iron core, each iron core part comprises a sub stator yoke and a stator tooth arranged on the sub stator yoke in a projected manner. The sub stator yoke comprises a first arc-shaped yoke part, a straight yoke part whose one end is connected with one end of the first arc-shaped yoke part, and a second arc-shaped yoke part whose one end is connected with the other end of the straight yoke part. The stator tooth is arranged on the first arc-shaped yoke part in a projected manner. The first arc-shaped yoke part and the second arc-shaped yoke part of one iron core part are respectively connected with the second arc-shaped yoke part and the first arc-shaped yoke part of the other iron core part. According to the invention, the winding efficiency of a stator winding is improved; sizes of end parts, projected from two ends of the stator iron core along the axial direction of the stator iron core, of the stator winding are reduced; the coil perimeter of the stator winding is reduced, the utilization rate of the stator winding is improved, and the cost of the series motor is lowered.

Owner:FOSHAN WEILING WASHER MOTOR MFG

Novel medical disinfection equipment

InactiveCN108066782AImprove thermal conductivityFast heat conductionHeatBiochemical engineeringMedical treatment

The invention discloses novel medical disinfection equipment. The novel medical disinfection equipment comprises a supporting seat, and a heat disinfection device and a winding device which are fixedly arranged at the front and rear sides of the top surface of the supporting seat, wherein the heat disinfection device is composed of a first support column and a second support column which are arranged oppositely; a connecting support column is fixedly arranged between top surfaces of the first support column and the second support column; the first support column is internally fixedly providedwith a first jointing part; the second support column is internally fixedly provided with a second jointing part; a first protruding part and a second protruding part are arranged at opposite sides ofthe first jointing part and the second jointing part respectively; a first barrel shaft is arranged between the first jointing part and the second jointing part; an inner cavity is arranged in the first barrel shaft; a plurality of iron sheets, which are arranged up and down in a staggered manner, are arranged in the inner cavity. The novel medical disinfection equipment disclosed by the invention is simple in structure; rapid installation can be realized in a winding process and the sanitation degree of bed sheets is improved; automatic tensioning can be realized through a spring coil; meanwhile, the disinfection effect is improved.

Owner:宁波市鄞州明联物联科技有限公司

a two-pole generator

ActiveCN105186723BGuaranteed StrengthGood value for moneyMagnetic circuit rotating partsMagnetic circuit stationary partsPunchingEngineering

The present invention discloses a two-pole generator. The structural features of the two-pole generator are that: a rotor punching is a two-pole special-shaped groove overall punching, an excircle of the rotor punching is an eccentric structure, and being different from a conventional square groove, the rotor punching adopts an inclined groove structure; two square grooves and two semi-circular grooves are arranged at the tooth parts, the square grooves are used to reduce the weight and increase the heat radiation area of a rotor iron core, and the semi-circular grooves are used to weld when being used as the rotor iron core, thereby forming weld joints; the rotor iron core forms an entirety via the damping bars and the weld joints, a stator punching is an overall punching, an excircle of the stator punching is equipped with seven semi-circular grooves and a mark groove, and the number of the semi-circular grooves also can be changed according to the actual demands; a stator iron core structure not having the buckle slabs and the clamping rings is adopted to weld in the seven semi-circular grooves and the mark groove of the excircle of the stator punching to form eight weld joints, so that a stator iron core can form a reliable entirety; the stator windings are square windings, and the end parts of the windings are square. The advantages of the present invention are that: the generator is small in size, light in weight and high in cost performance, is convenient to process, and is espeialy suitable for the medium and small size two-pole generator.

Owner:KUNGFU SCI TECH CO LTD

a dust collector

ActiveCN107227600BQuick installationQuick releaseMechanical cleaningPressure cleaningAutomatic controlConductor Coil

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

A textile winding mechanism

ActiveCN107215710BUniform winding workAvoid affecting the processing processFilament handlingMechanical engineeringTextile

The invention discloses a convenient and rapid type textile winding mechanism which comprises a winding frame body composed of a first frame main body and a second frame main body. The first frame main body is internally provided with a cavity arranged in a left-right extension mode; a first sliding groove is formed in the inner front wall of the right side of the cavity; a sliding block is arranged in the first sliding groove, wherein the rear side of the sliding block extends into the cavity, and the sliding block is slidably connected with the first sliding groove in a matched mode; a hinging piece is arranged on the end face of the left side of the sliding block in the cavity; a hinging pushing rod extending towards the left side is hinged into the hinging piece; a hinging sleeve is arranged at the tail end of the left side of the hinging pushing rod; a U-shaped hinging rod is sleeved with the hinging sleeve; the front side end of the U-shaped hinging rod is rotatably connected with the inner wall of the front side of the cavity in a matched mode; the rear side end of the U-shaped hinging rod is connected with a winding motor in a matched mode; the outer surface of the winding motor is embedded in the inner wall of the rear side of the cavity and is fixedly connected with the inner wall of the rear side of the cavity; a second sliding groove arranged in a front-rear extension mode is formed in the end face of the left side of the second frame main body; and a moving block is arranged in the second frame main body. The structure is simple, quick mounting and dismounting can be realized, the replacing speed of a thread cylinder is increased, and winding work can be evened.

Owner:河北澜浩羊绒制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com