Integrated segmented forming micro-inductor manufacturing process

A process technology and micro-inductor technology, which is applied in the field of integrated segmented forming micro-inductor process technology, can solve the problems of low current resistance of non-wound inductors, unfavorable mass production, small saturation current, etc., and achieves strong current resistance capability, Reduced risk of short circuit, high saturation current effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present utility model more clearly.

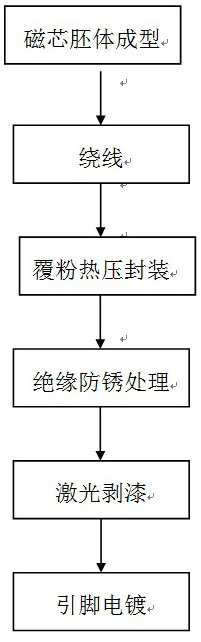

[0028] Such as figure 1 , an integrated segmented micro-inductance manufacturing process, comprising the following steps:

[0029] (1) Magnetic core embryo forming

[0030] The magnetic powder is pressed into an "I" or "T" type magnetic core preform body through a cold pressing die, the powder particles of the magnetic powder used are 100~200 mesh, and the bulk density is 2.0~2.5g / cm 3 . The magnetic core preform prepared by cold pressing is baked at 210°C for 3 to 9 minutes or at 120°C for 30 to 60 minutes to obtain a magnetic core blank with a certain strength including a magnetic column and a base body, and the density of the magnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com