Paying-off tensioning equipment for vertical winding of transformer coil

A technology of transformer coils and tensioning equipment, which is applied in the direction of inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc. It can solve problems affecting electrical performance, difficulty in tensioning coils, and torsion damage to wires, etc., to improve winding Manufacturability, simple device structure, avoiding the effect of poor manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

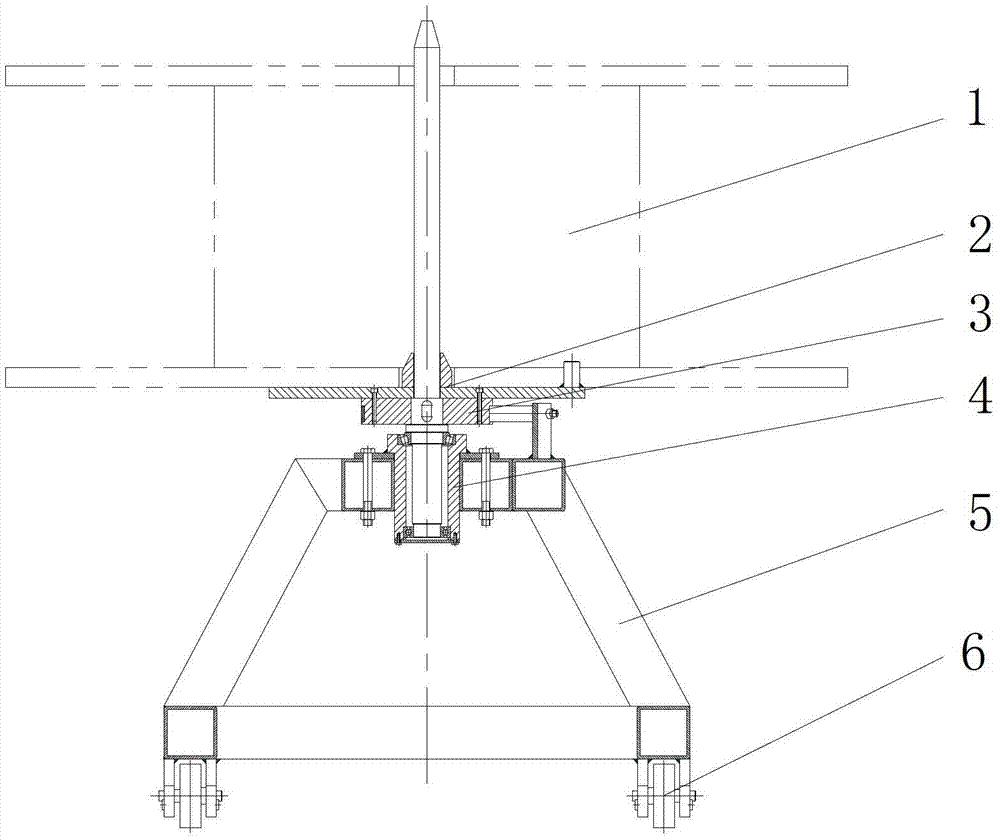

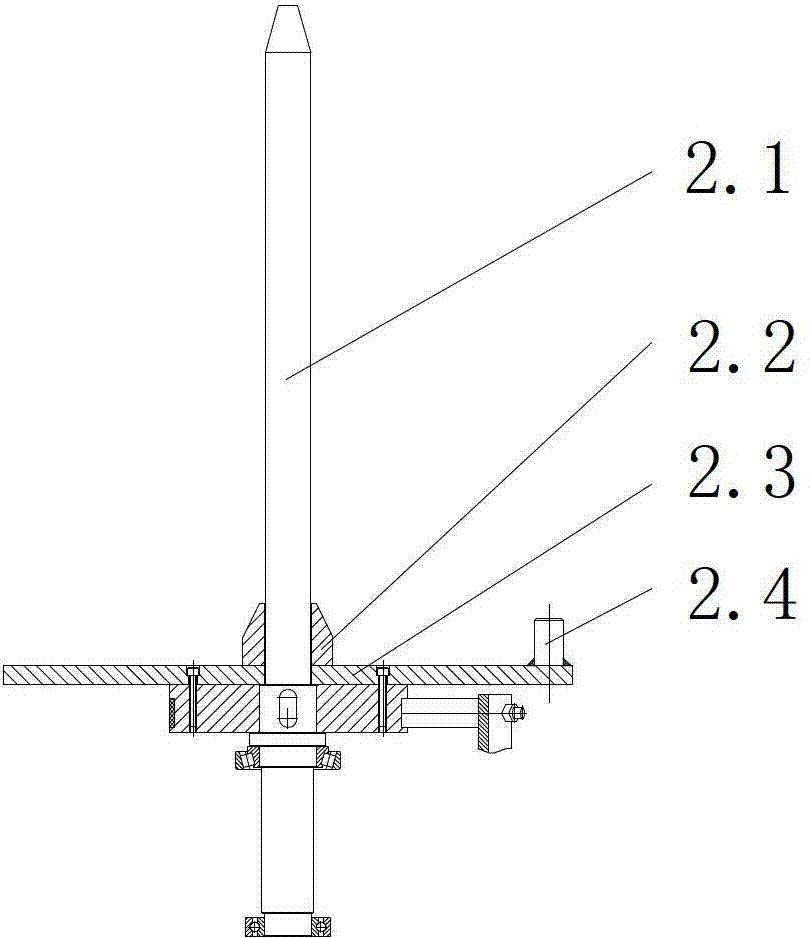

[0025] A pay-off and tensioning device for vertical winding of transformer coils, such as figure 1 As shown, including reel fixing device, tensioning device, bearing housing device, frame and wheel device,

[0026] The wire reel fixing device is used for vertically placing the wire reel in the axial direction and fixing the transposition wire reel in the circumferential direction;

[0027] The tensioning device is fixedly connected with the wire reel fixing device by screws, and is used to control the tension degree of the tensioning device for unwinding;

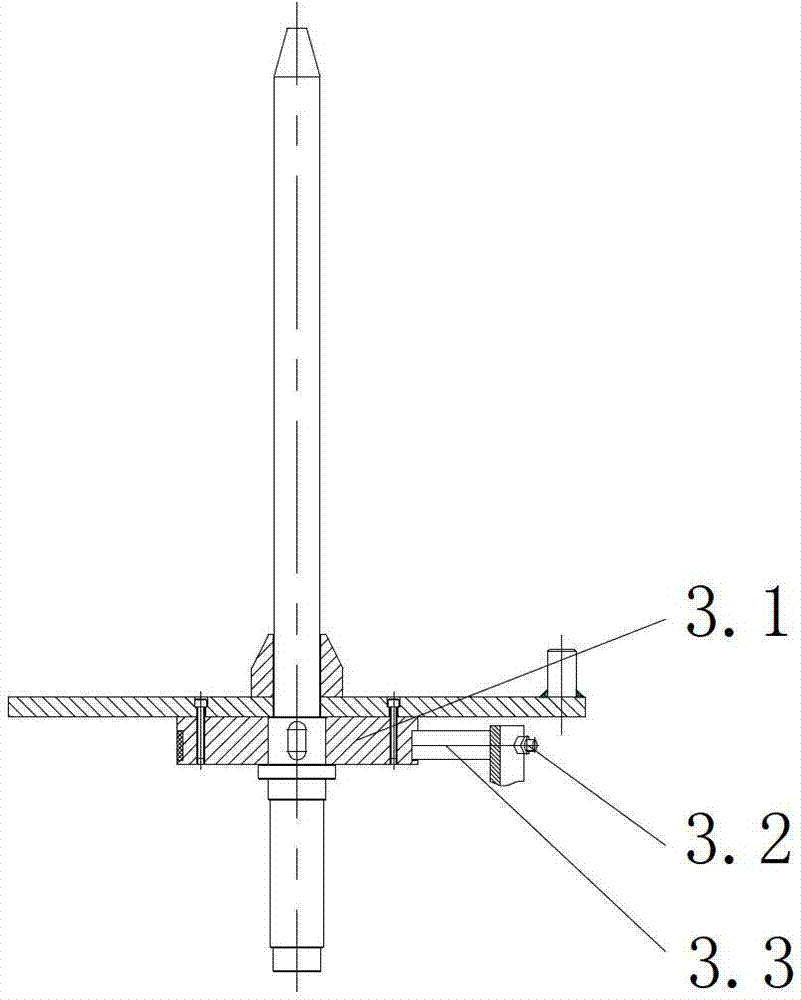

[0028] the bearing housing device, which constitutes the rotational connection between the reel fixing device and the frame, and bears the weight from the transposed wire reel, reel fixing device and tensioning device;

[0029] The frame is used to stabilize the center of gravity of the pay-off ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com