Winding process of stator interphase coil

A stator coil and winding technology, which is applied in the field of motor stator production technology, can solve the problems that the quality of the coil at the end of the stator cannot meet the requirements, affect the coil shaping at the end of the stator, and the length of the bridge line of the phase coil, so as to reduce the length, Improve cleanliness and improve the effect of end flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

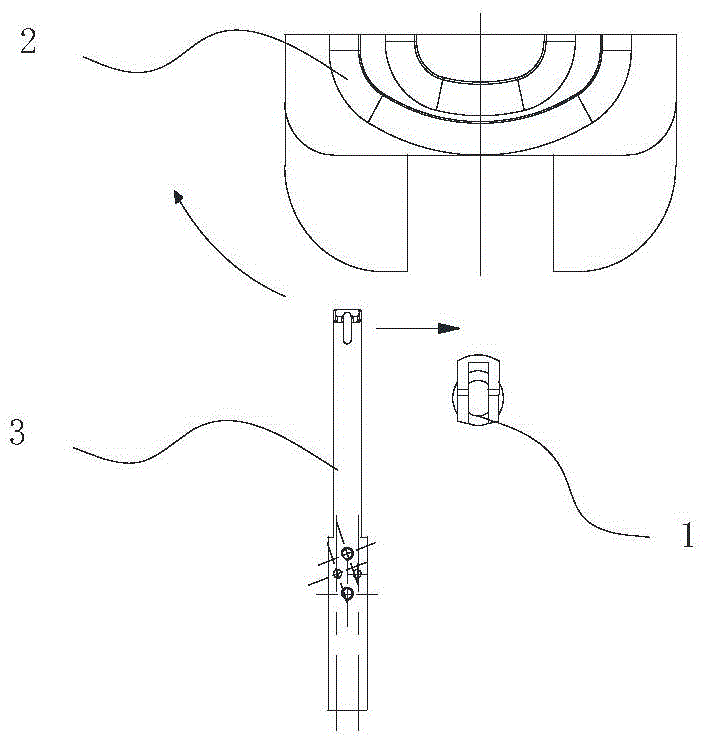

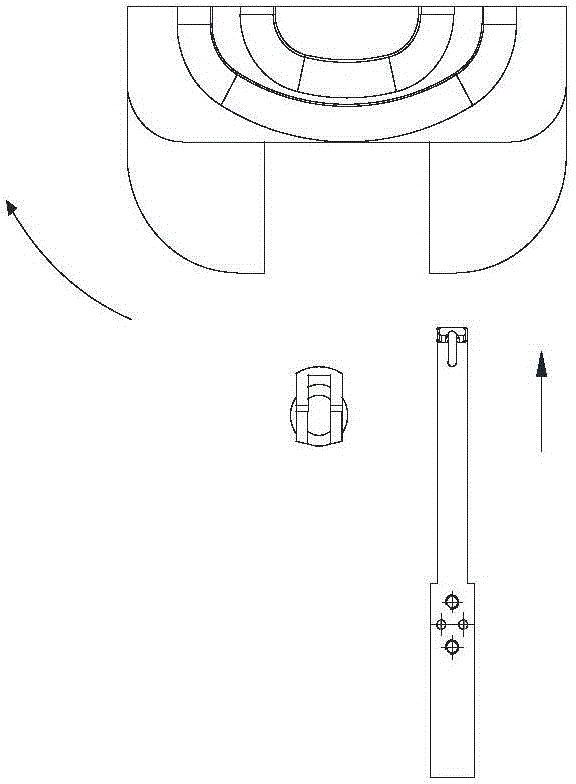

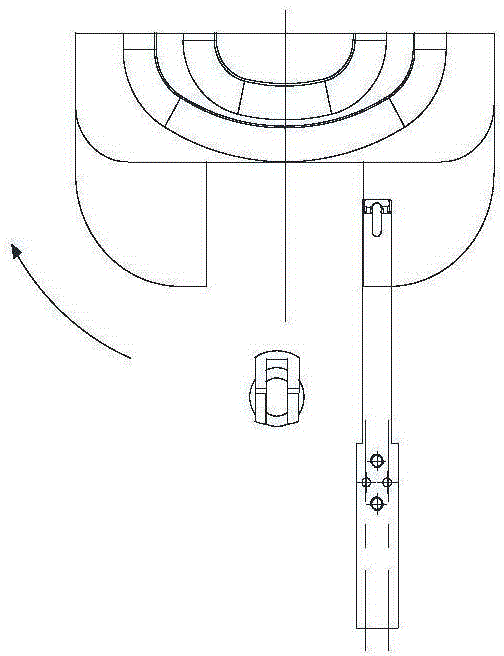

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] In the production process of the stator, in the prior art, the stator coil with the set phase number is pre-winded on the hanging cup by the winding machine, and then the stator coil is embedded in the stator by the wire embedding machine, and each During the winding process of the coils between phases, there must be bridge lines connecting the coils of each phase between each phase.

[0027] Such as Figure 1 to Figure 3 In the above-mentioned winding process in the prior art, the enameled wire is directly clamped after the feeding and shearing mechanism moves laterally, and the feeding and shearing mechanism moves forward to feed the wire after clamping, which inevitably causes a gap between the winding mold and the feeding and shearing mechanism. The folded part or slack part of the enameled wire causes the length of the bridge wire to be too long and the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com