Low-power single-phase condenser motor and method for adjusting capacitance and turn number thereof

A motor, low-power technology, applied in asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of multiple winding turns, complex electromagnetic calculation, and easy disconnection of single-phase capacitor motors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

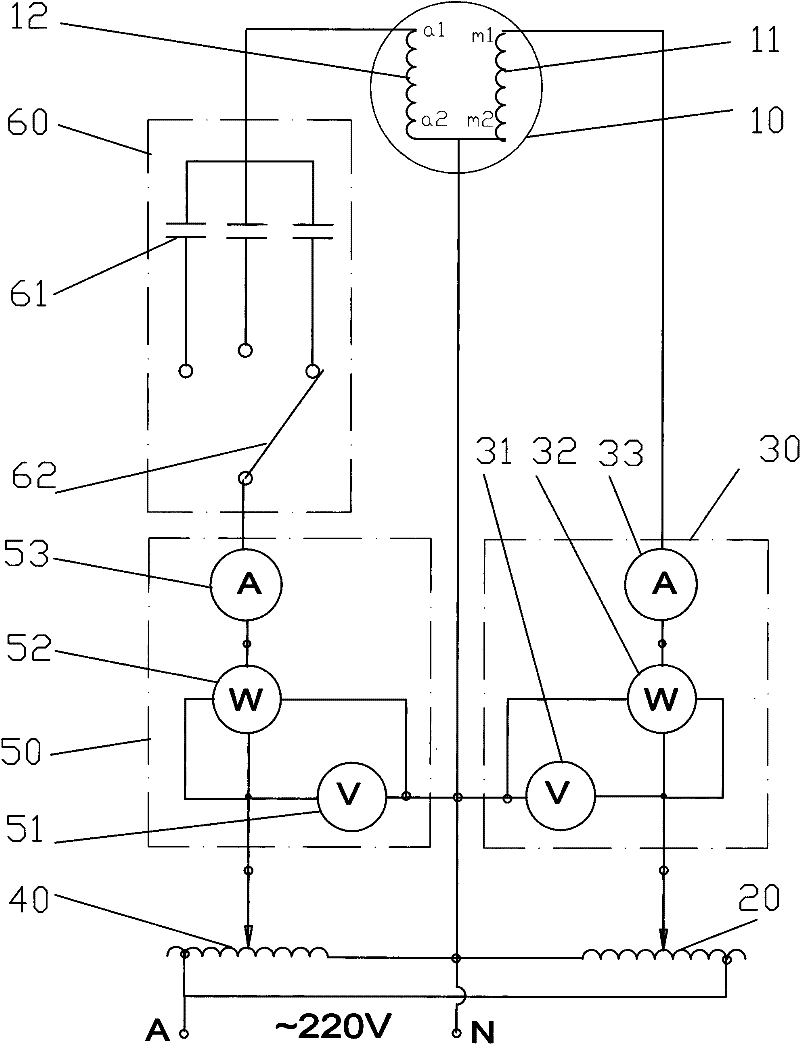

[0022] The low-power single-phase capacitor motor in the embodiment of the present invention is improved on the basis of the common single-phase capacitor-operated asynchronous motor in the prior art.

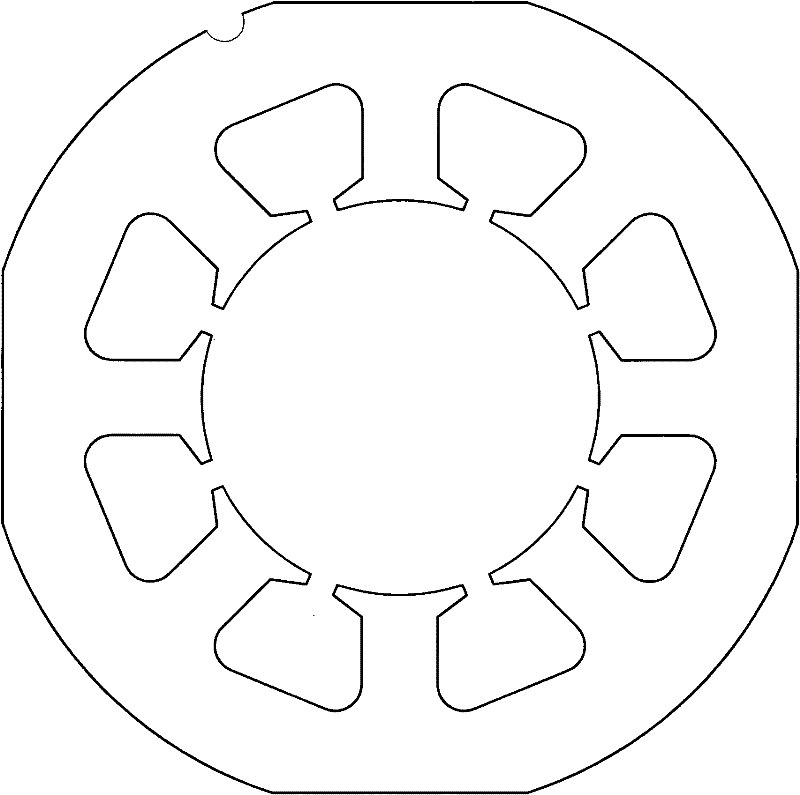

[0023] The motor is an inner rotor motor, including a stator and a squirrel cage rotor. Stator core punching sheet such as figure 1 It is square and rounded, with 8 slots with uniform opening and flat bottom (it can also be heterosexual slots, closed slots and round bottom slots), 4 of the 8 teeth are located on the symmetry axis of the 4 straight line segments, and the other 4 teeth are located on the 4 corner arcs The axis of symmetry of the segment, each tooth is wound around a coil element 6 with an insulating frame.

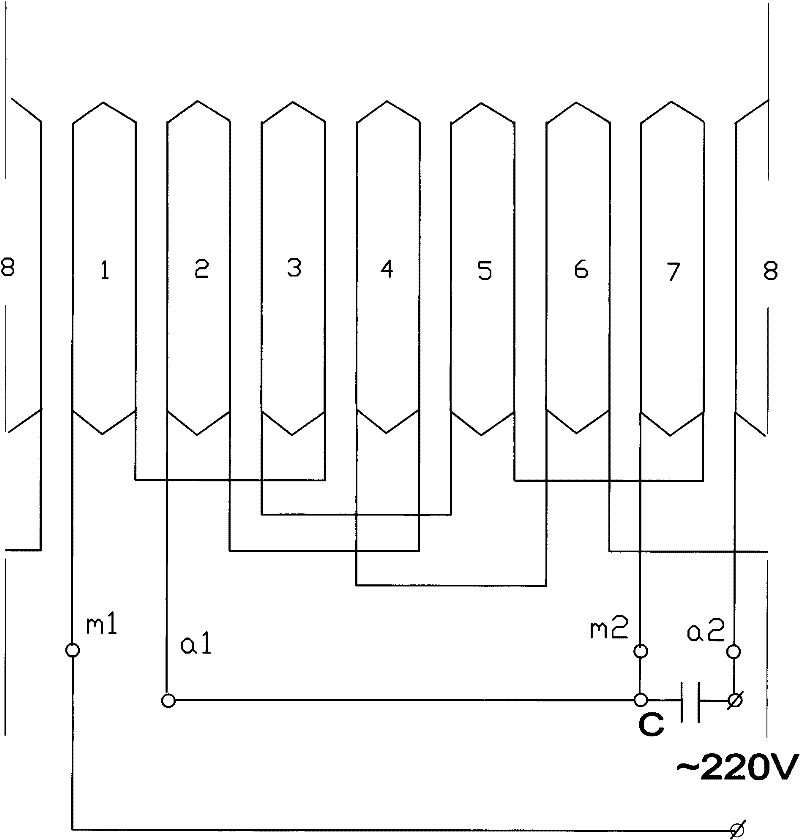

[0024] Winding construction and wiring such as figure 2 . The main phase winding connected to terminals m1 and m2 is formed by the symmetry axis located on the straight line section of iron core 5 punching piece 4 (see figure 1 ) serial numbers are 1, 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com