Automatic textile winding device

A winding device and automatic technology, which is applied in the field of textile processing, can solve problems such as single structure, bobbin falling off, increasing economic cost, etc., and achieve the effect of improving installation stability, facilitating installation and disassembly, and improving the overall process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

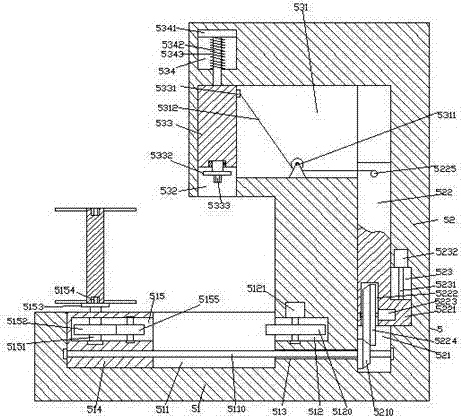

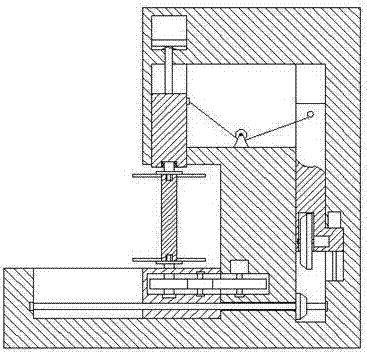

[0024] Such as Figure 1-Figure 5 As shown, an automatic textile winding device of the present invention includes a winding body 5 composed of a first body 51 and a second body 52 fixed on the right side of the first body 51. The first body 51 A first sliding groove 511 is arranged in the top end surface of the right side, and a first sinking groove 512 is arranged in the left end surface of the second body 52 in the first sliding groove 511, and the first sinking groove 512 is rotationally fitted and connected. There is a first toothed wheel 5120, the top of the first toothed wheel 5120 is connected with the first motor 5121, and the second body 52 on the right side of the first sinker 512 is provided with a second vertically extending Sliding groove 521, a third sliding groove 523 is provided in the inner wall on the right side of the second sliding groove 521, and a first threaded rod 5231 extending longitudinally is arranged in the third sliding groove 523, and the first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com