Multilayer film punching device

A punching device and multi-layer film technology, applied in the field of processing machinery, can solve the problems of slow manual punching, high product price, time-consuming and labor-intensive, etc., and achieve convenient installation and maintenance, improve processing quality, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

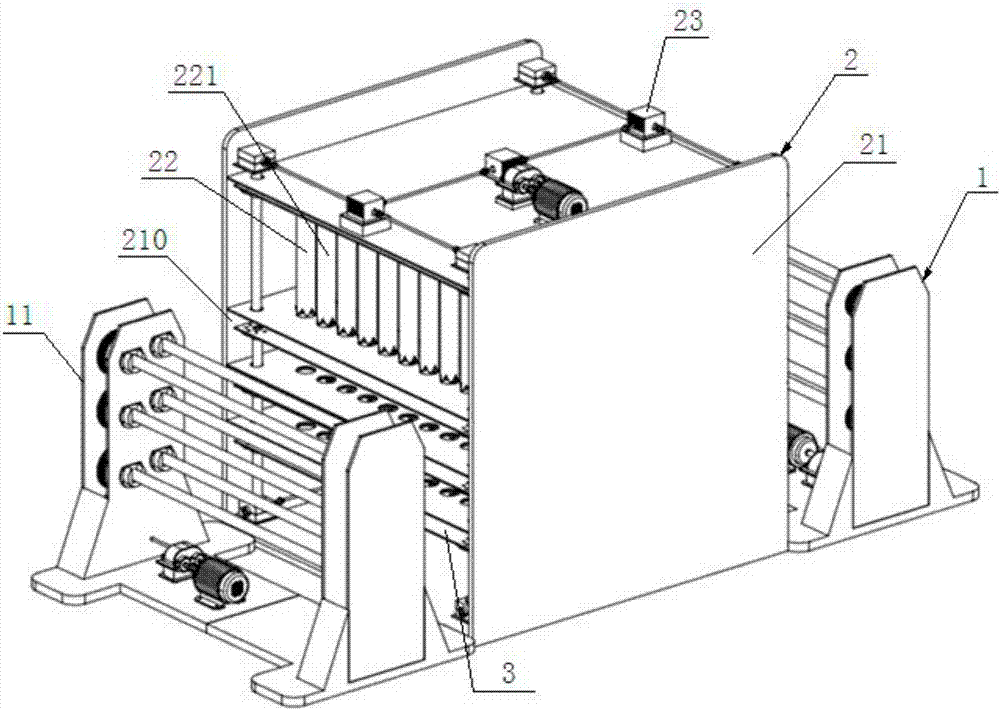

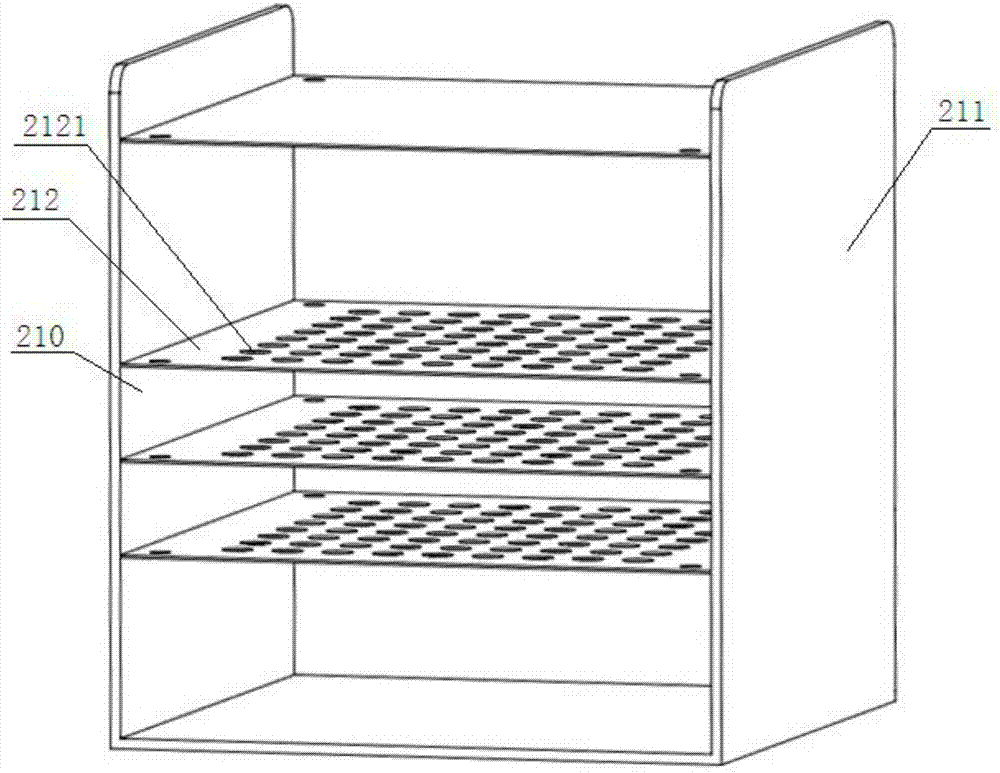

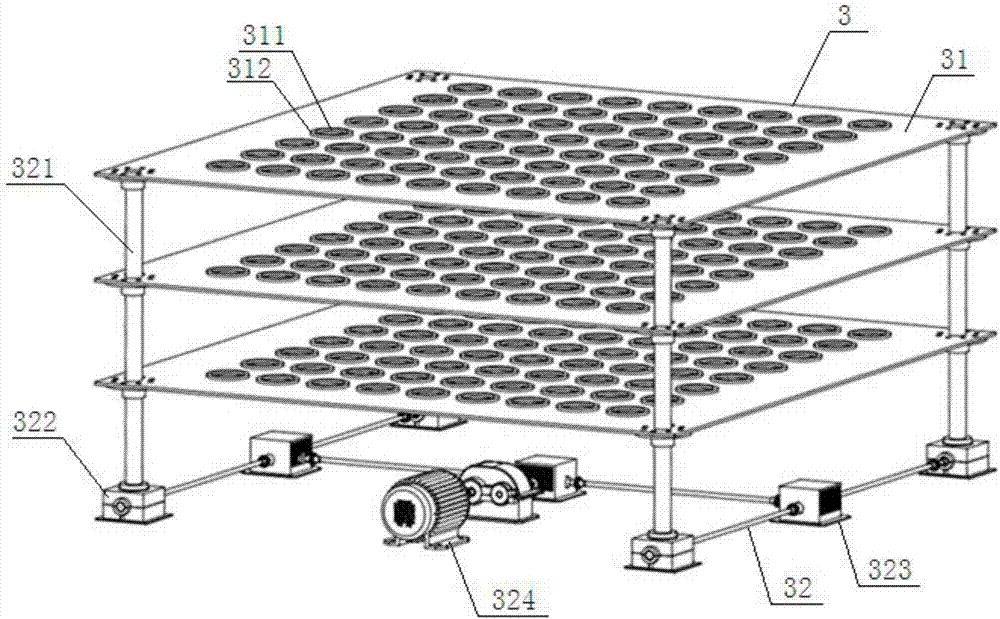

[0027] According to the attached Figure 1 to Figure 10 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

[0028] see Figure 1 ~ Figure 3 , the present invention provides a kind of multi-layer film punching device, comprises a conveying assembly 1, a punching assembly 2 and a controller (not shown); The punching assembly 2 includes a frame 21, a knife rest mechanism 22 and A knife rest transmission mechanism 23; the frame 21 forms a plurality of film passages 210 along the horizontal direction, and the film passages 210 are stacked and arranged at intervals along the vertical direction; the frame 21 forms a plurality of knife channels communicated with the film passage 210 along the vertical direction; The knife rest mechanism 22 can be fixed on the frame 21 reciprocatingly along the vertical direction through the knife rest transmission mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com