CUSP magnetic field generator coil and processing method thereof

A magnetic field generating device and coil technology, which is applied in coils, coil manufacturing, chemical instruments and methods, etc., can solve the problems of affecting the service life of CUSP magnetic field devices, difficult processing, easy deformation, etc., and achieve shortening of waterway distance and manufacturing process arrangement Reasonable, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following examples can make those skilled in the technical field understand the present invention more comprehensively, but do not limit the present invention in any way.

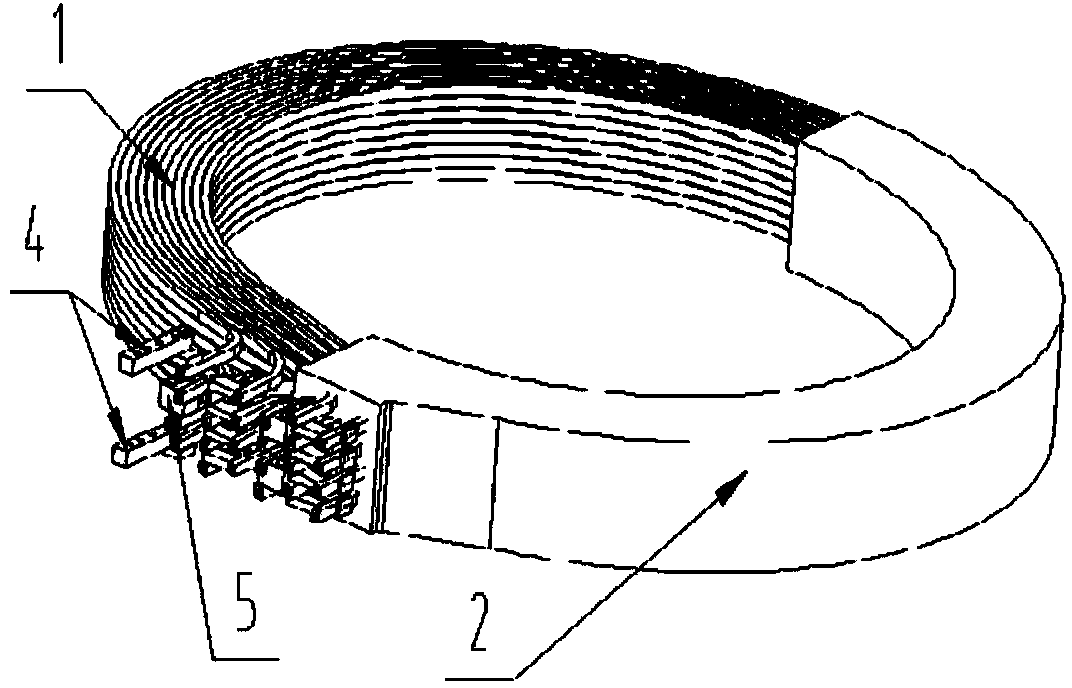

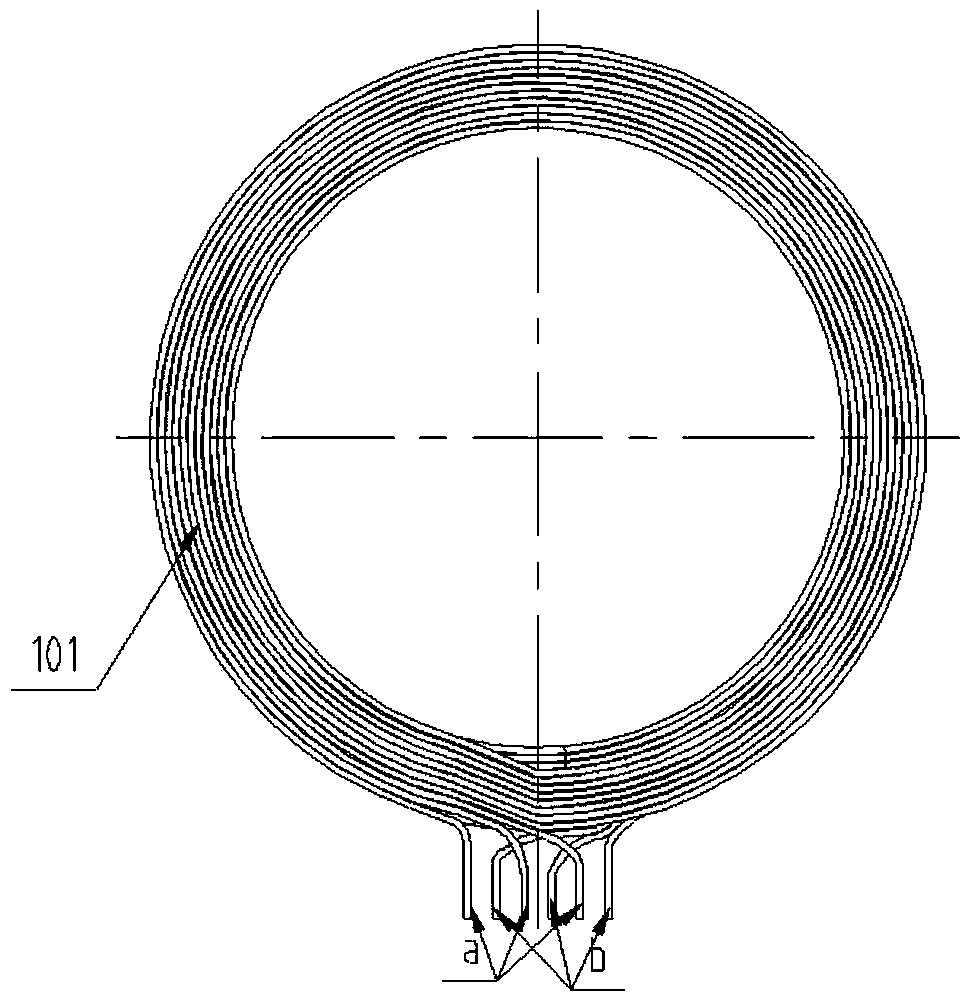

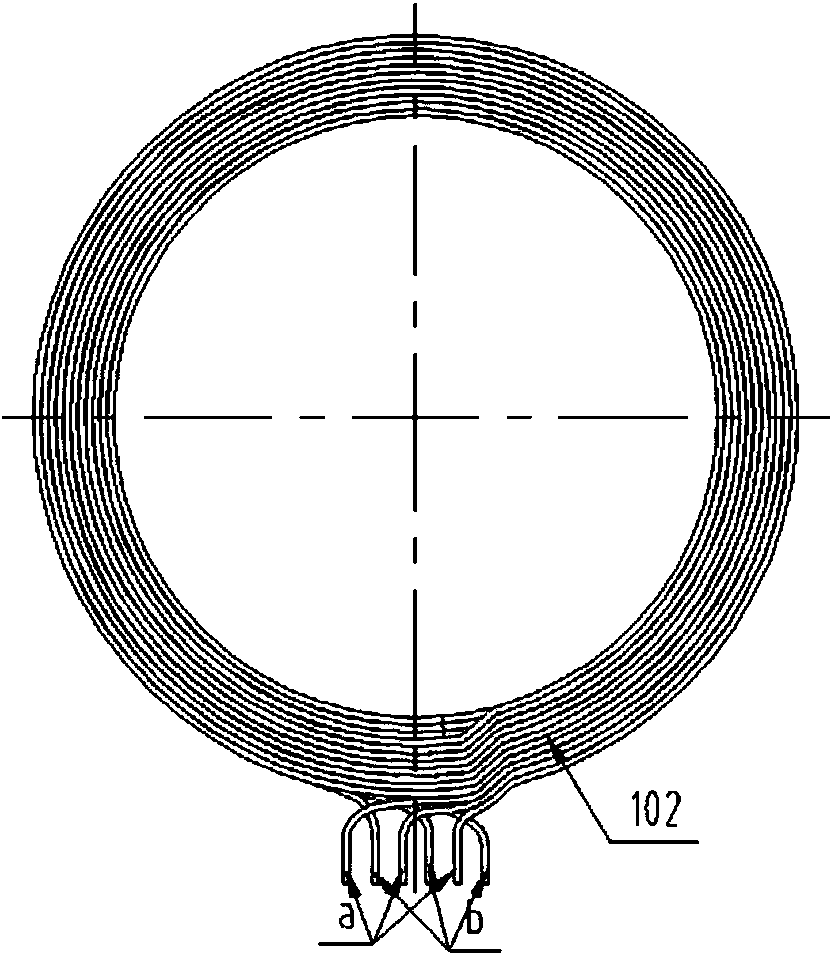

[0046] figure 1 Shown in is a schematic diagram of a coil with 8 axial turns and 10 radial turns. For the convenience of understanding, only half of the epoxy resin 2 is shown. figure 2 and image 3 are schematic diagrams of coil unit I101 and coil unit II102 respectively, Figure 4 A schematic diagram of the cross-section of the coil.

[0047]The present invention provides a coil of a CUSP magnetic field generating device, comprising a cylindrical coil group 1 wound by a copper tube 1011, one side of the coil group 1 is provided with a water inlet and outlet, an epoxy resin 2, an insulating plate 3, an electrode 4, The connection block 5; the insulating plate 3 is arranged between the copper pipes 1011, and the epoxy resin 2 is cast to cover the entire coil group 1; the connection block 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com