Direct torque control method and device of brushless continuous current dynamo

A technology of direct torque control and brushed DC motor, applied in the direction of single motor speed/torque control, electronic commutator, etc., can solve the problems of large torque ripple and high complexity of torque calculation, and reduce the control cycle , Realize torque ripple suppression and improve the effect of torque hysteresis regulator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

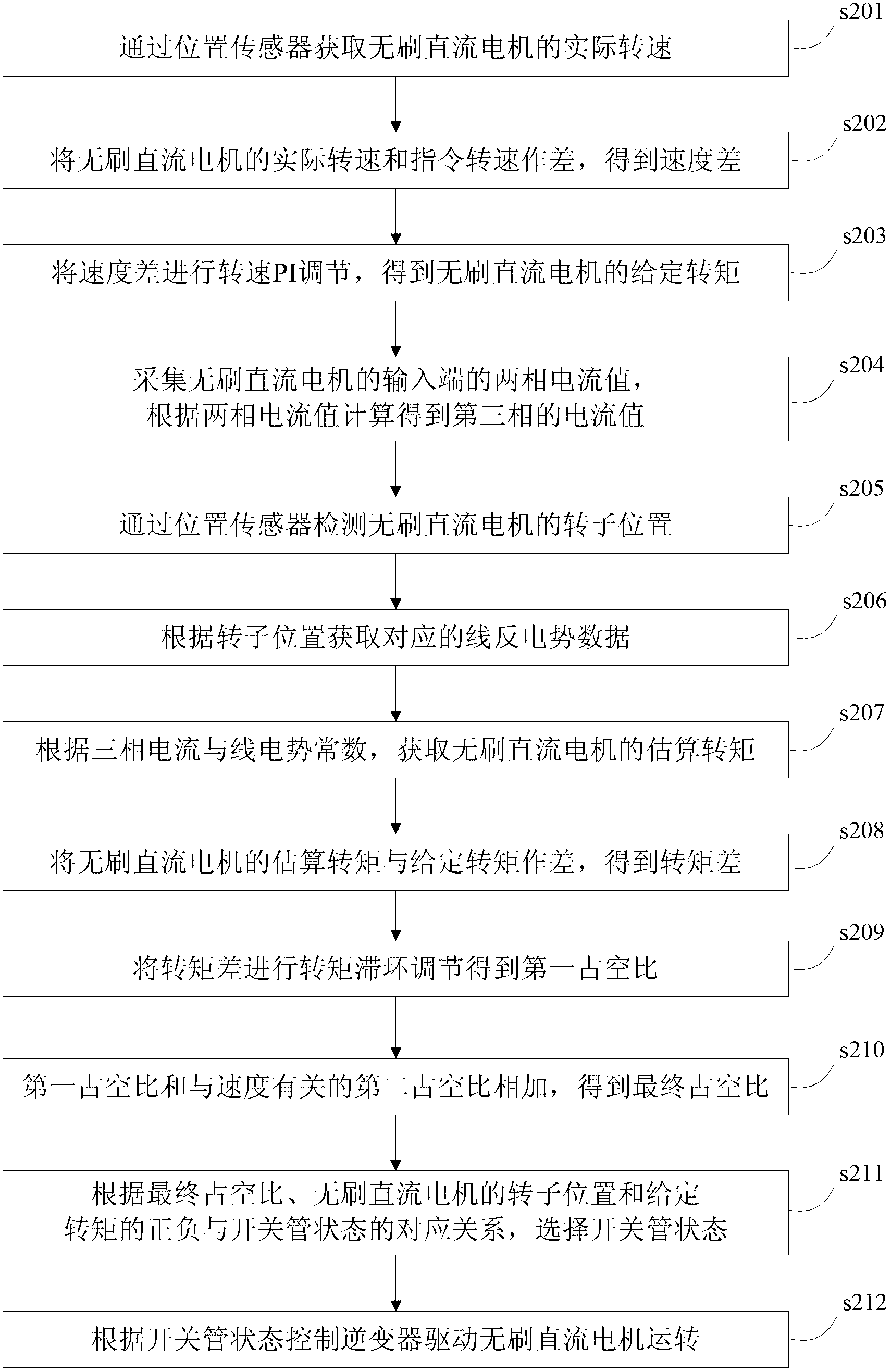

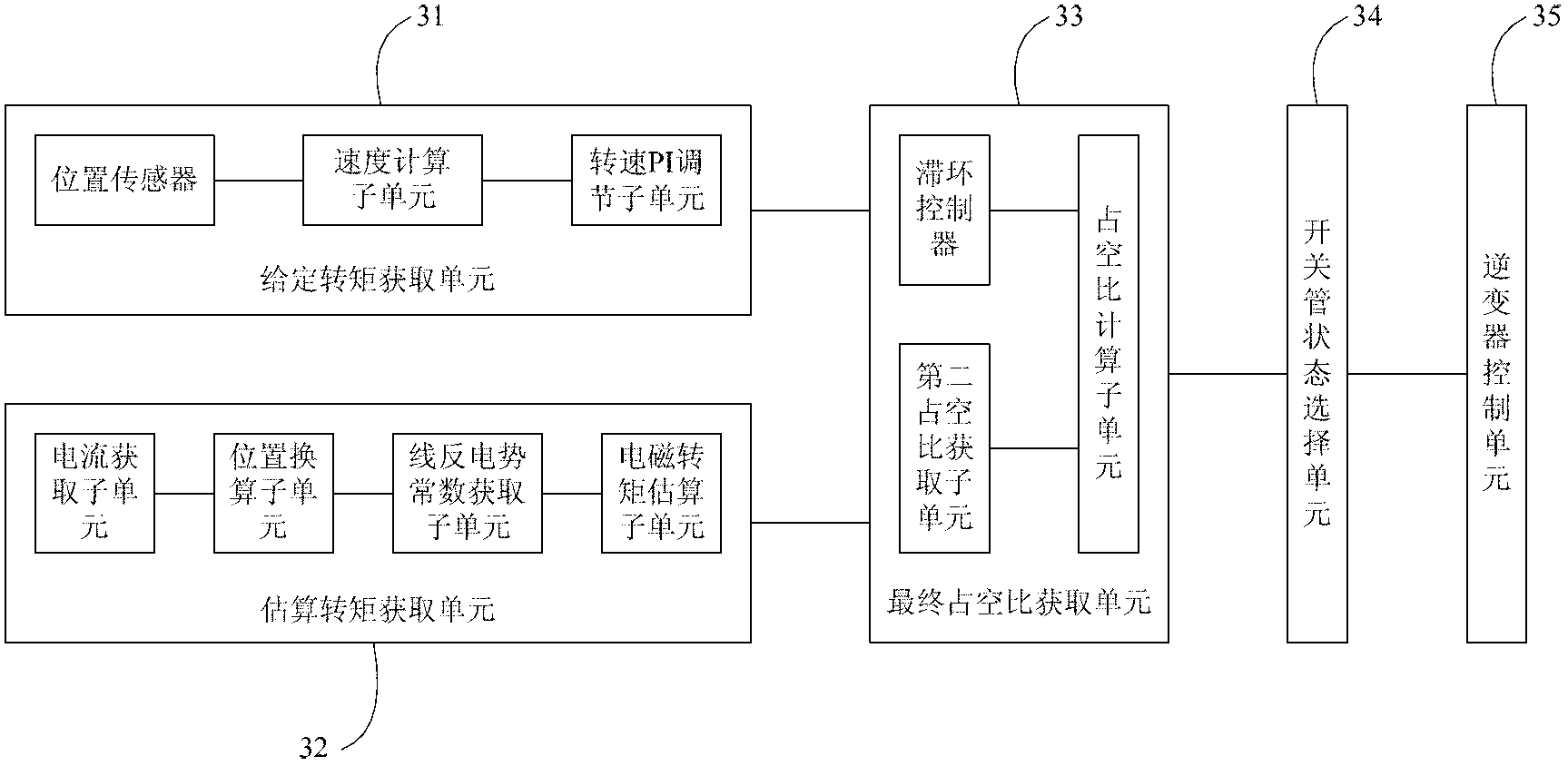

[0065] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

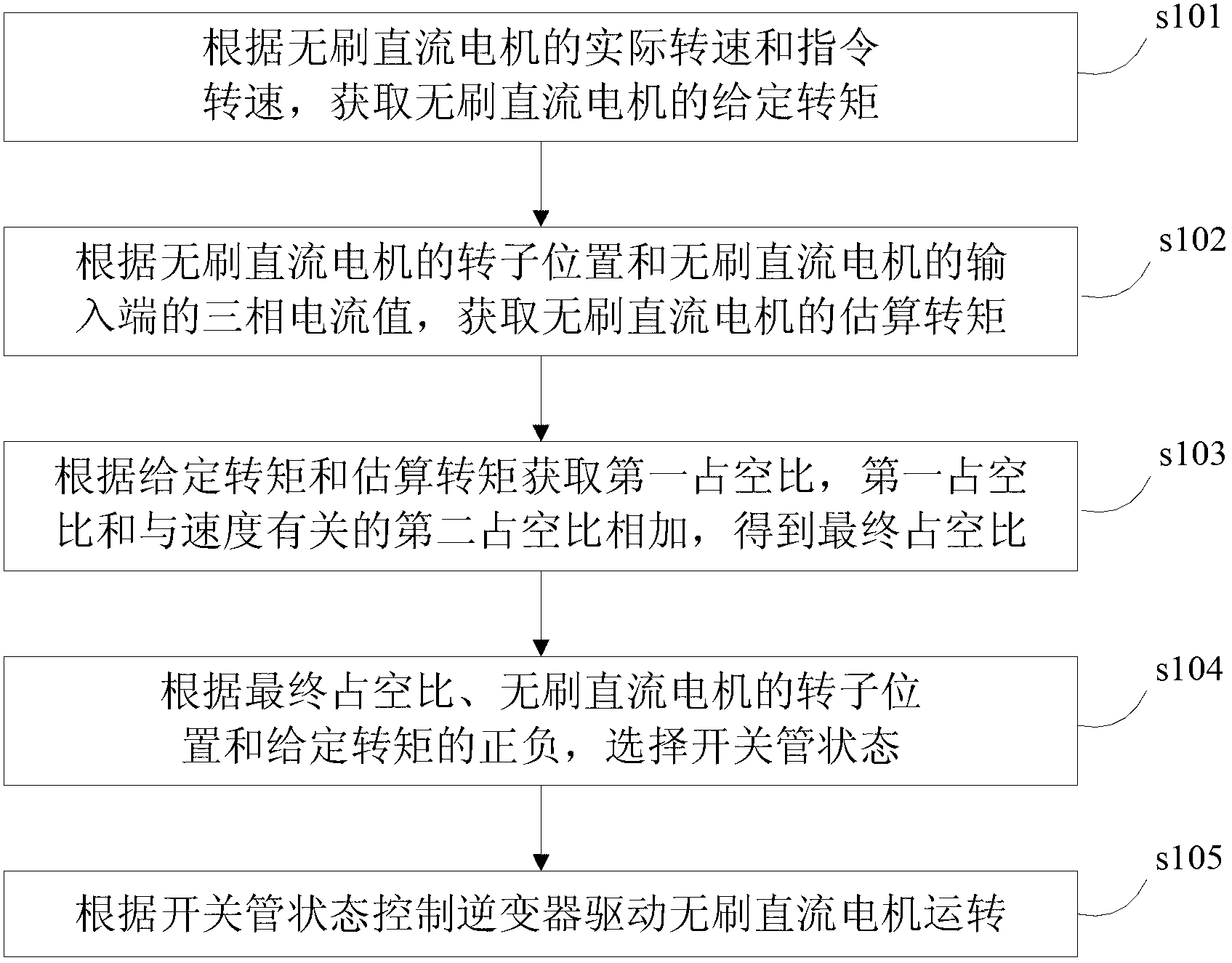

[0066] A direct torque control method of a brushless DC motor according to an embodiment of the present invention is as follows: figure 1 shown, including the following steps:

[0067] Step s101, according to the actual rotational speed and command rotational speed of the brushless direct current motor, obtain the given torque of the brushless direct current motor.

[0068] Step s102, according to the rotor position of the brushless direct current motor and the three-phase current value of the input end of the brushless direct current motor, the estimated torque of the brushless direct current motor is obtained.

[0069] Step s103, obtaining a first duty ratio according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com