Magnetic resistant electric motor with double stator switch

A switched reluctance motor, double stator technology, applied in electrical components, electromechanical devices, magnetic circuit shape/style/structure, etc., can solve the problems of large torque ripple, small number of teeth, application limitations, etc., to achieve low torque ripple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

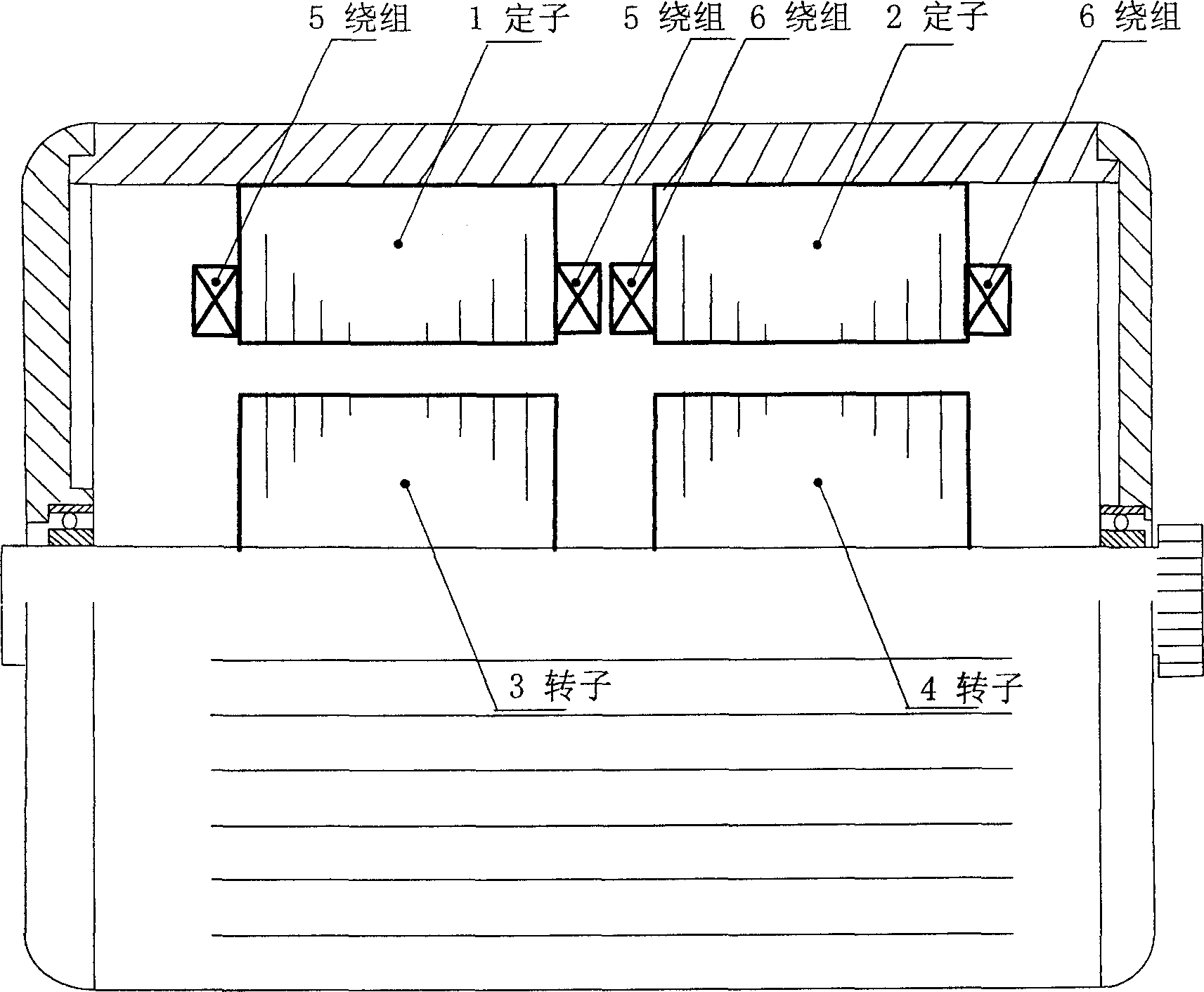

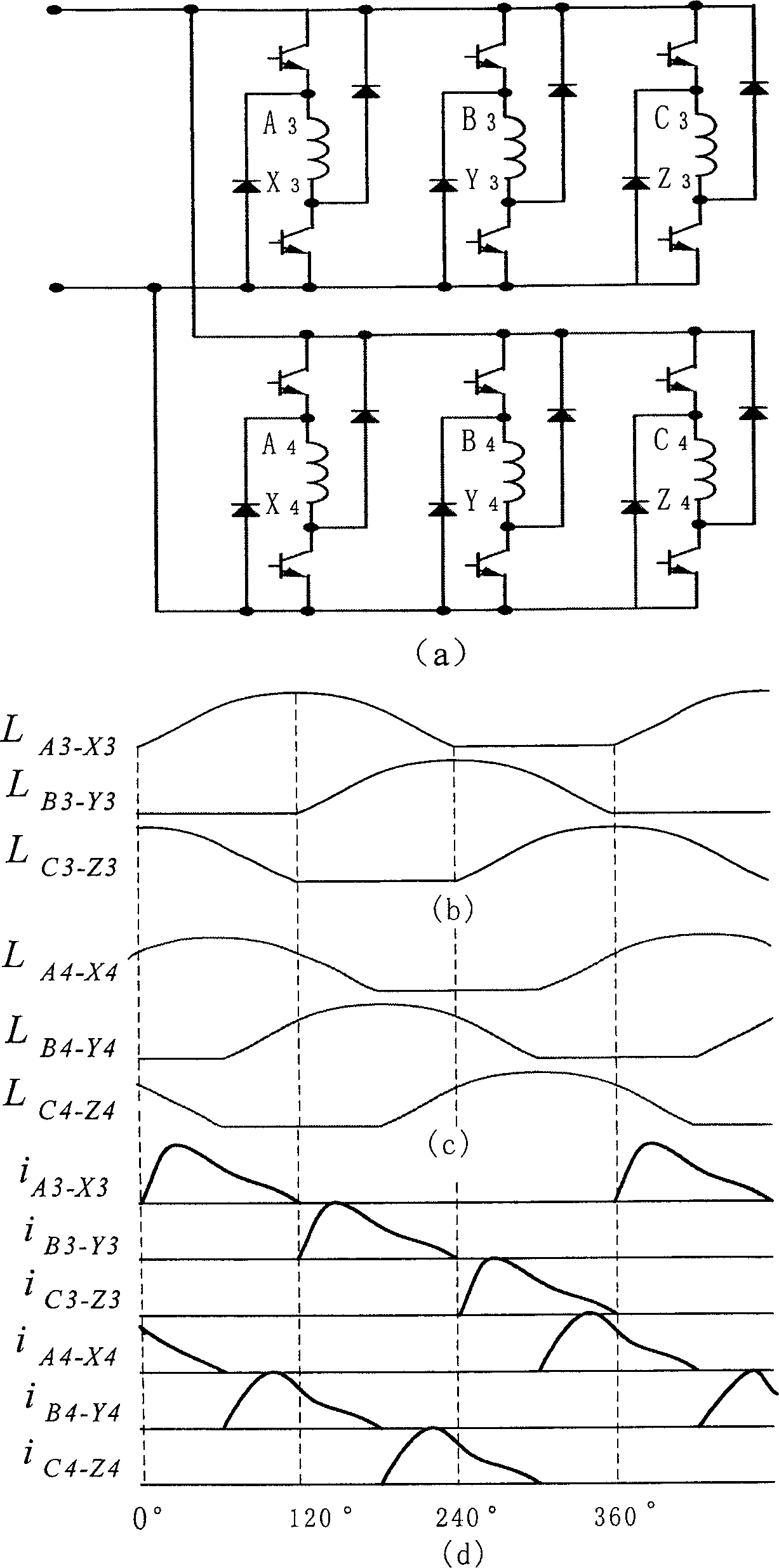

[0022] Since the working principles of the double-stator switched reluctance motors with different phases are similar, the structure of the present invention and the principle of reducing torque ripple will be described below by taking the three-phase 6 / 4 structure double-stator switched reluctance motor as an example.

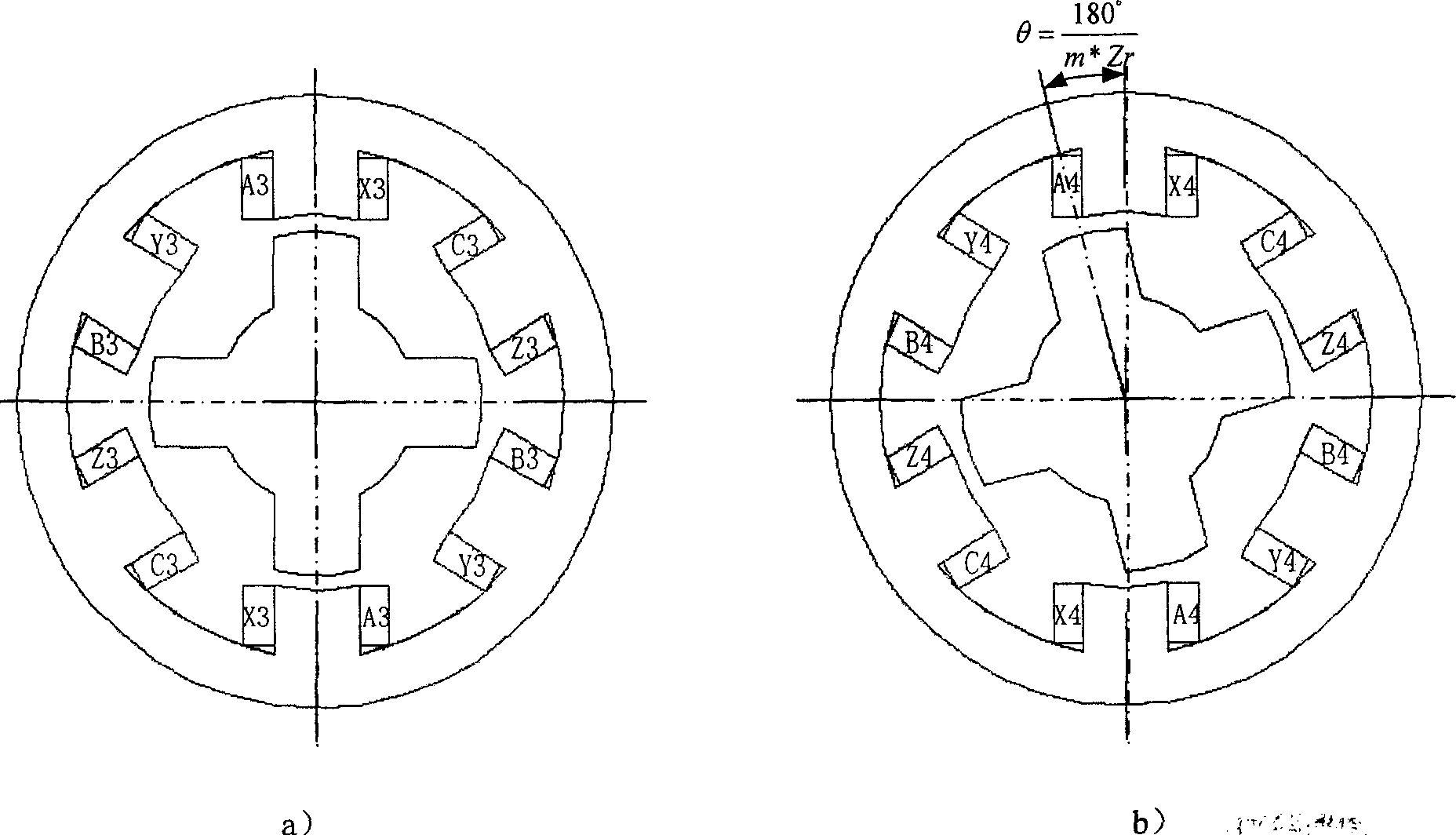

[0023] The stator and rotor iron cores of the double-stator switched reluctance motor of the present invention are composed of two sections, and the lengths of the two iron cores are the same. As shown in Figure 1 and Figure 2, it is a structural schematic diagram of a three-phase 6 / 4 structure double-stator switched reluctance motor . The stators 1, 2 and the rotors 3, 4 are all made of laminated silicon steel sheets, and have a salient pole slot structure. The three-phase motor has a 6N / 4N (N is a positive integer 1, 2, 3, 4...) structure, that is, the number of stator teeth is 6N, and the number of rotor teeth is 4N. For example, if N=1, it is a three-phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com