Structure for modular motor stator and end part overlapping fractional slot windings of modular motor stator

A motor stator and winding structure technology, applied in the shape/style/structure of winding conductors, electric components, magnetic circuit shape/style/structure, etc., can solve the unfavorable large motor production, transportation and maintenance, non-working harmonic content Many, unable to modularize the motor and other problems, to achieve the effect of strong fault tolerance, small mutual inductance between phases, and small cogging torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The working mechanism and advantages of the present invention will be described in more detail below through a specific embodiment and related drawings.

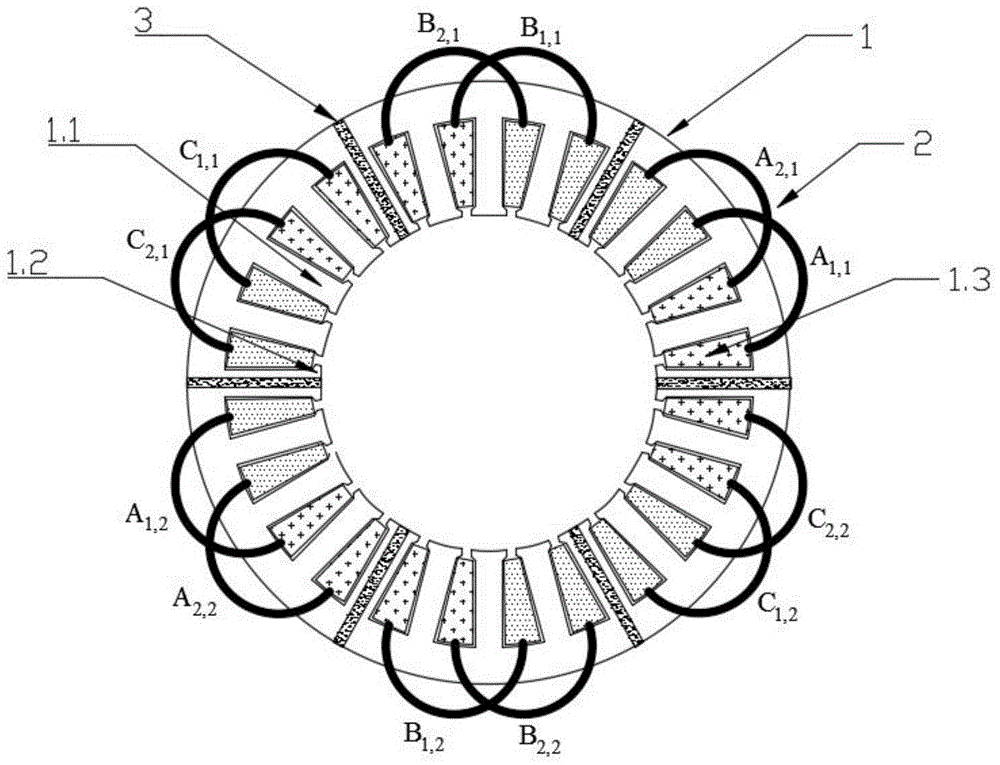

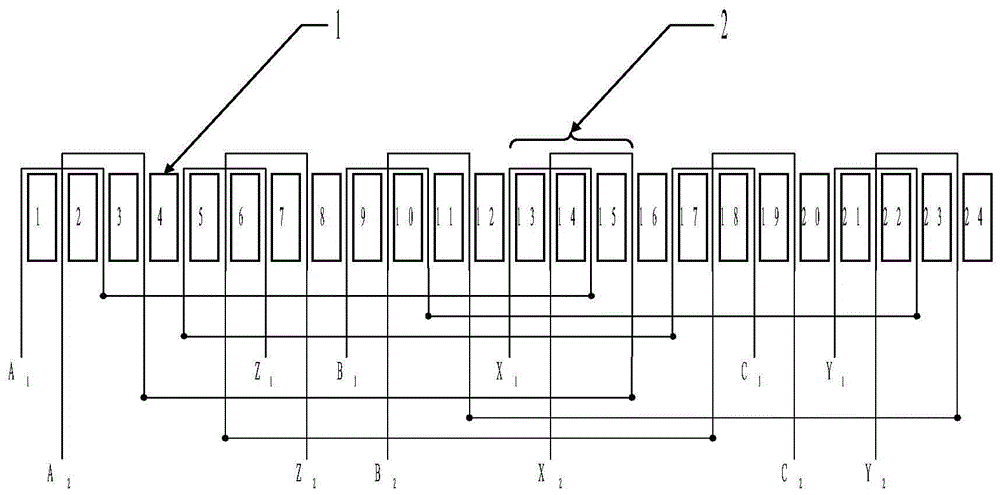

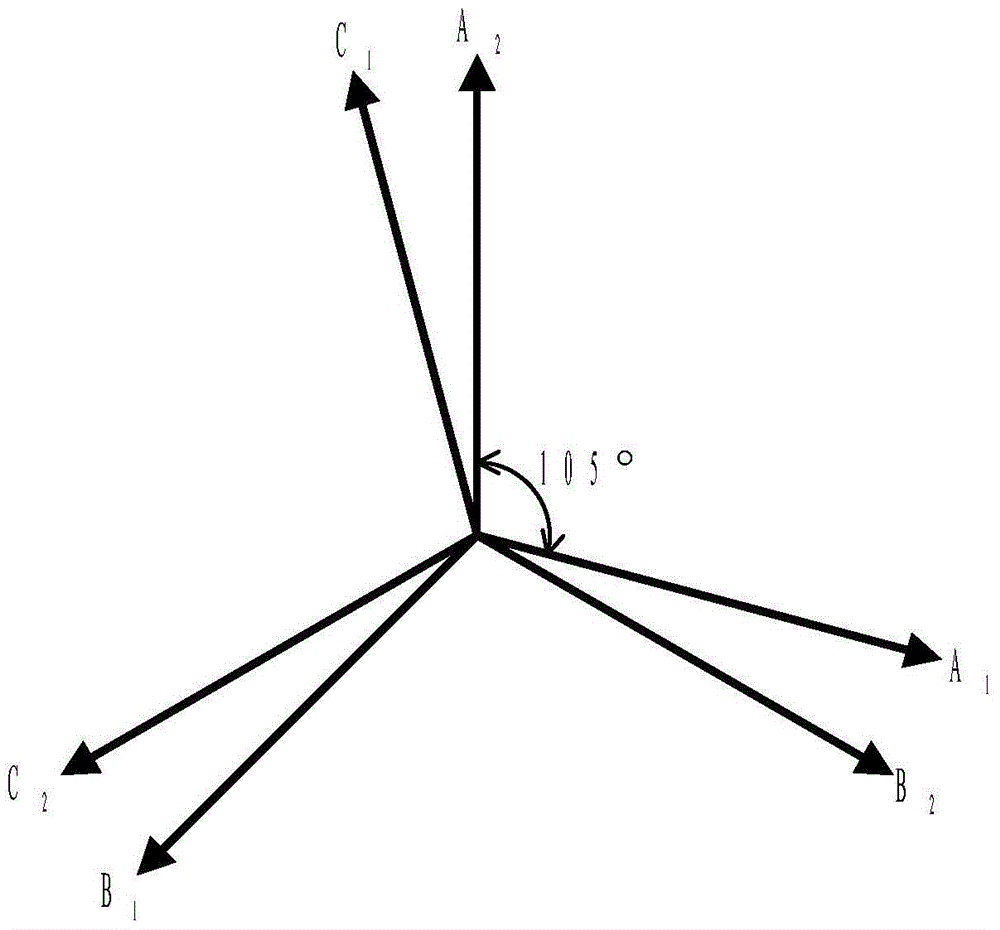

[0022] Such as figure 1 Shown is a schematic diagram of a 24-slot 7-pair permanent magnet synchronous motor stator and its end windings using a modular motor stator and its end overlapping fractional slot winding structure. The stator 1 includes armature teeth 1.1 , fault-tolerant teeth 1.2 , stator slots 1.3 and a non-magnetic isolation layer 3 . Stator 1 is wound with end-overlapping fractional slot winding 2, which is composed of two sets of three-phase symmetrical AC windings as a whole. Each stator slot 1.3 contains only one coil edge, and the entire winding 2 has 12 coils in total. The distribution of overlapping parts on the circumference of the stator is discontinuous, and the stator can be cut into several modules along the junction of the overlapping areas of two adjacent end windings. The motor has 6 stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com