Motor drive apparatus having oscillation-reducing control function for output torque

A motor-driven, vibration-reducing technology, applied in engine-driven traction, AC motor control, motors, etc., can solve problems such as vehicle vibration and driver discomfort, and achieve the effect of preventing step parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

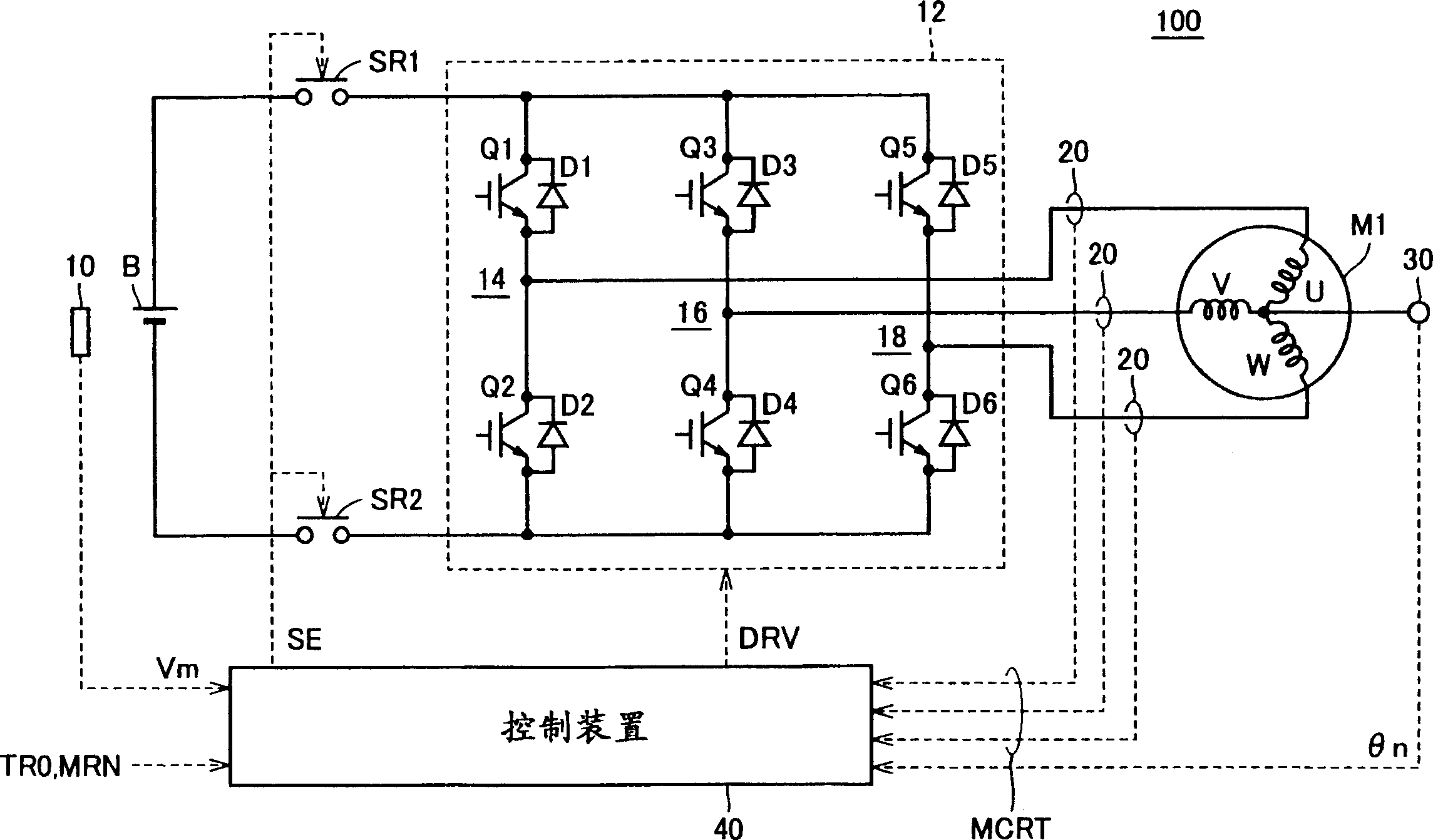

[0068] figure 1 is a schematic block diagram of the motor drive device according to the first embodiment of the present invention.

[0069] refer to figure 1 , the motor drive device 100 includes a DC power supply B, a voltage sensor 10 , an inverter 12 , a current sensor 20 , a resolver (resolver) 30 and a control device 40 .

[0070] The AC motor M1 is a drive motor for generating torque to drive drive wheels of a hybrid vehicle or an electric vehicle. The AC motor M1 also functions as a generator driven by the engine and as an electric motor for the engine, and thus has, for example, the ability to start the engine.

[0071] Inverter 12 is composed of U-phase arm 14 , V-phase arm 16 and W-phase arm 18 . U-phase arm 14 , V-phase arm 16 , and W-phase arm 18 are provided in parallel (in parallel) between the power supply line and the ground line.

[0072] U-phase arm 14 is composed of NPN transistors Q1, Q2 connected in series. V-phase arm 16 is composed of NPN transist...

no. 2 example

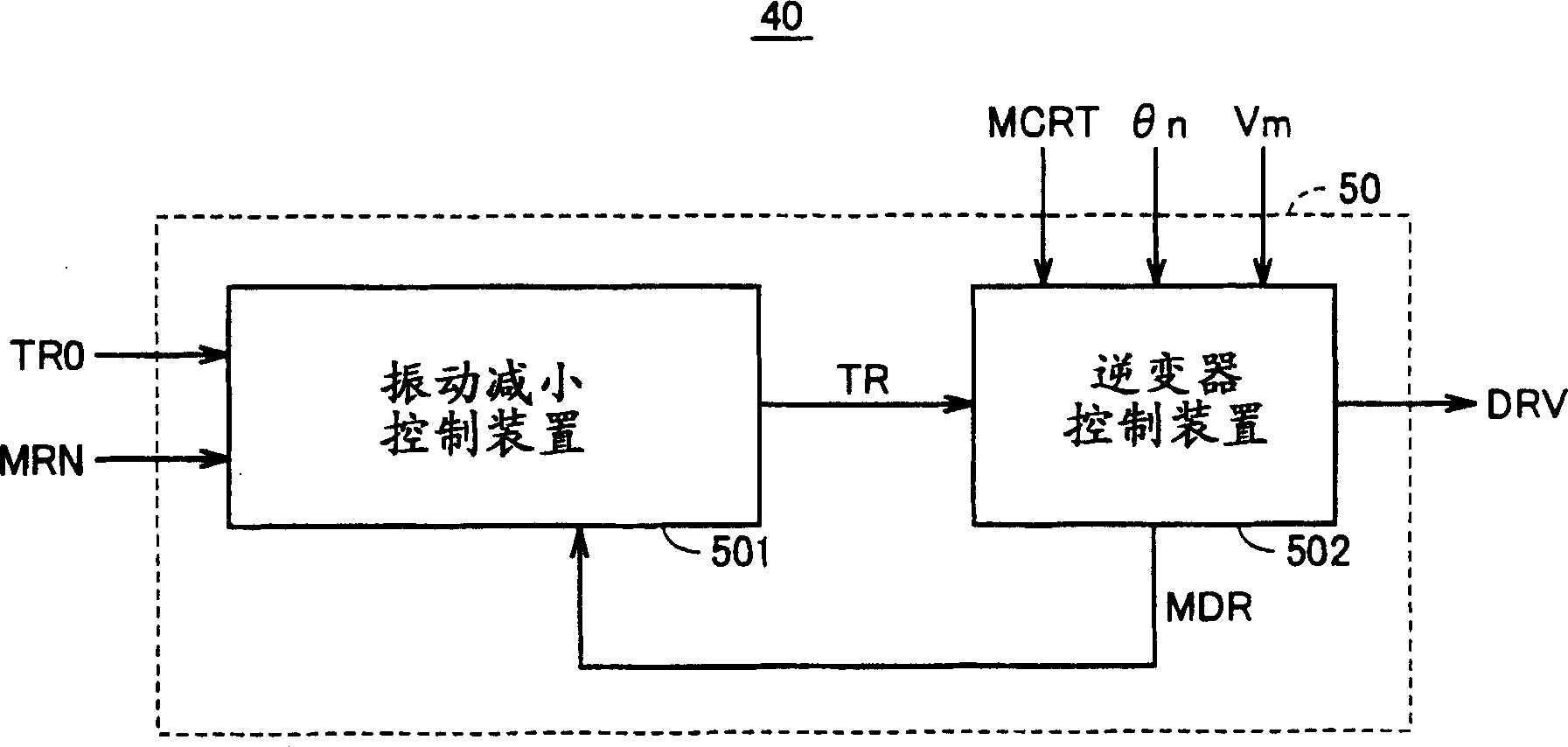

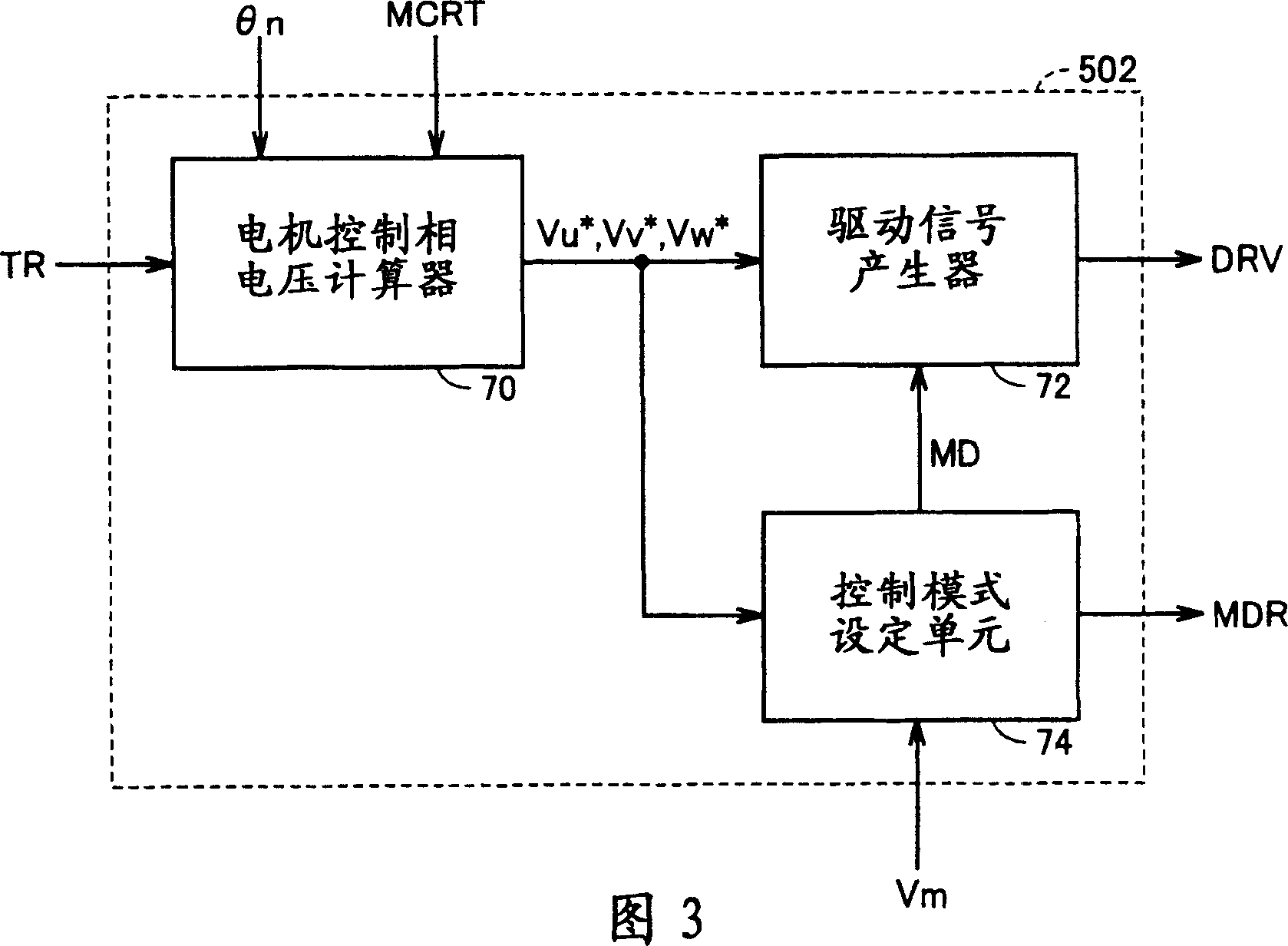

[0156] As described above in connection with the first embodiment, the vibration reduction control device 501 of the present invention generates the vibration reduction torque Δtr based on the reverse phase component of the rotation number variation component ΔMRN of the motor rotation number MRN. The inverter control device 502 adds the externally supplied torque command value TR0 to the vibration reducing torque Δtr, and the sum is used as a final torque command value TR for driving the AC motor M1. Thereby, the vibration of the output torque of AC motor M1 can be reduced, and comfortable driving can be realized. In particular, the vibration reduction control is effective in any situation that induces vibration of the vehicle such as a sudden change in the torque command value TR0 of the AC motor M1.

[0157] However, when the vehicle is in a normal running state or stopped and in a no-load state, any slight change in the output torque will cause any behavior of the vehicle,...

no. 3 example

[0184] In the second embodiment described above, the method of employing the vibration reduction control in the case where the variation amount of the drive torque applied to the drive wheels is large has been described.

[0185] as combined Figure 13A-1 As described in 3C, the amount of change in the drive torque output from motor generator MG2 varies depending on the state of the vehicle.

[0186] Therefore, when the vibration reducing control is performed, the magnitude of the vibration reducing torque can be changed according to the change amount of the driving torque to enhance the effect of the vibration reducing control.

[0187] Specifically, when the change amount of the driving torque is large, the vibration reduction torque correction unit 62 of the vibration reduction control device 501 corrects by multiplying the vibration reduction torque Δtr0 by a large correction coefficient Km. For example, when the engine is started, a large torque is applied to motor gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com