Stator surface mounted doubly salient pole permanent magnet motor

A stator surface, permanent magnet motor technology, applied to synchronous motors with rotating armatures and static magnets, synchronous machine parts, magnetic circuit static parts, etc., can solve short circuits, serious magnetic leakage, and reduce unit magnetism Utilization and other issues, to achieve the effect of high efficiency, reduced copper consumption, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

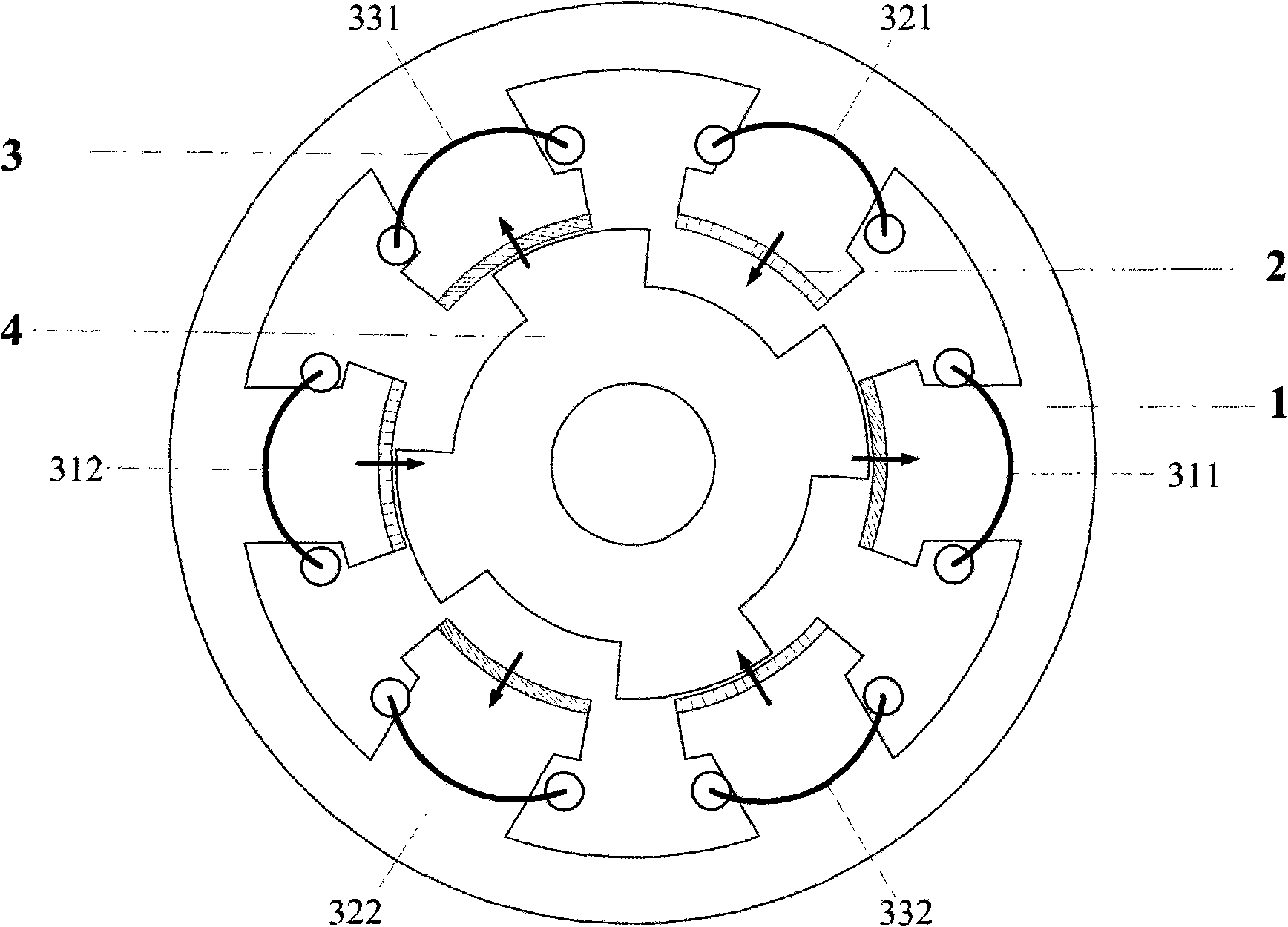

[0016] The stator surface-mounted double salient permanent magnet motor of the present invention includes two parts, the stator and the rotor. According to different application occasions, two forms of inner rotor or outer rotor can be adopted. Both the stator and the rotor are double salient pole structures, and the stator slots Number N s and the number of rotor salient poles P r There are many kinds of coordination, and the number of motor phases m can be single-phase, two-phase, three-phase and multi-phase; there are concentrated windings and permanent magnets on the stator; among them, the concentrated winding of any phase is composed of (N s / m) coils, and the m-phase coils are successively sleeved on the stator teeth. Each stator slot is a double-layer winding, that is, there are coil sides belonging to two different phases; the coils belonging to the same phase (N s / m) winding coils can be connected in series / parallel / series-parallel as required; each stator tooth i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com