Wind power plant generation device

A technology for wind power generation devices and generators, which is applied in the direction of wind power engines, wind power motor combinations, transmission devices, etc., which can solve the problems of complex motor structure and difficult processing and manufacturing, and achieve the effects of good power quality, simplified structure, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

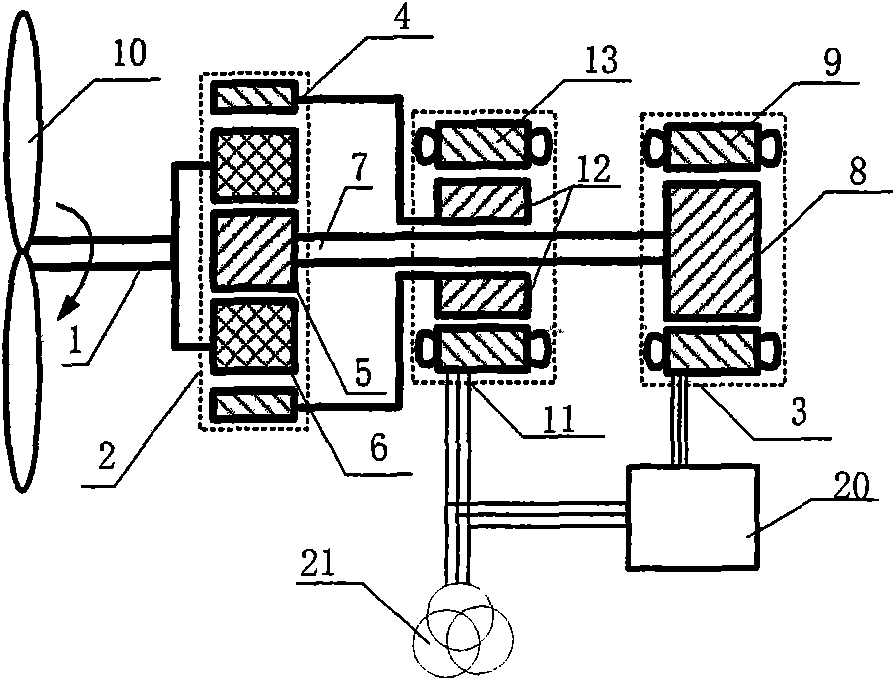

[0028] The invention includes two parts: an active stepless speed regulating device and a wind power generating device.

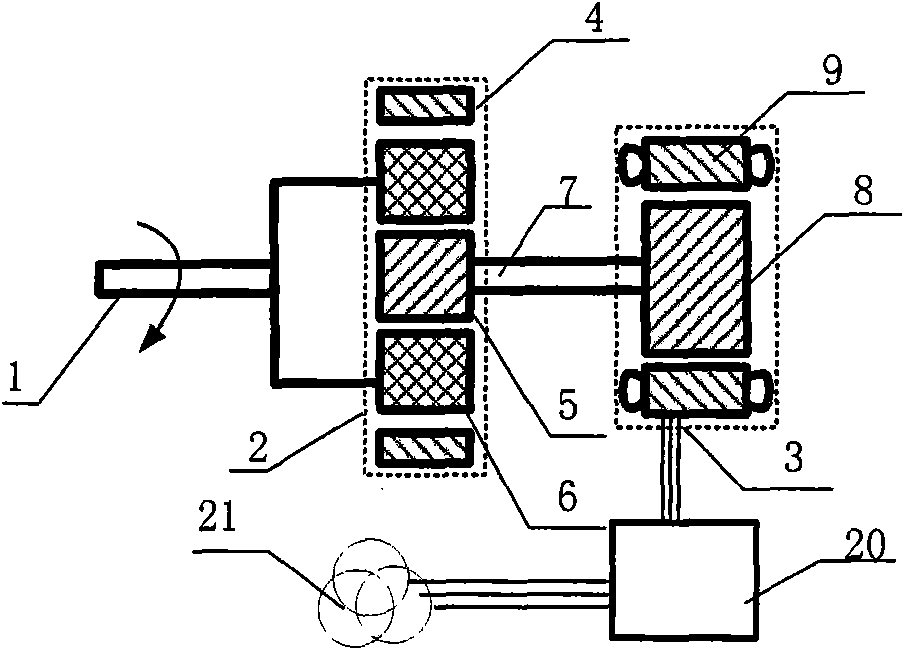

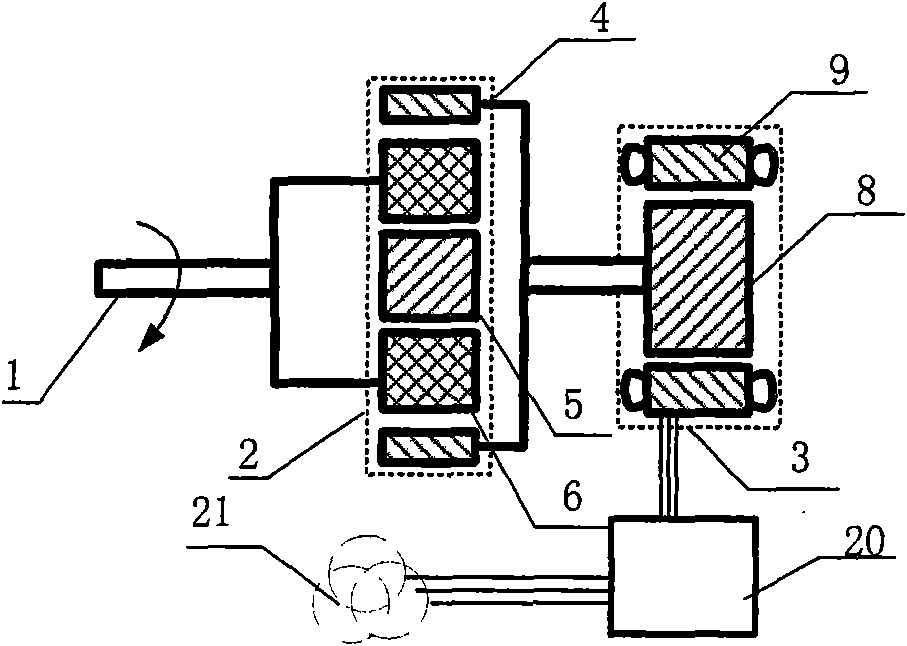

[0029] The speed regulating device of the present invention is as figure 1 and figure 2As shown, it includes a motor 3 , a planetary gear 2 and a power converter 20 . Planetary gear 2 is made up of outer ring gear 4 , planet carrier 6 and sun gear 5 . The power converter 20 supplies power to the speed-regulating motor 3 , the mechanical output shaft 1 is connected to the planet carrier 6 of the planetary gear 2 , and the rotor 8 of the speed-regulating motor 3 is connected to the sun gear 5 of the planetary gear 2 through the mechanical output shaft 7 . Planetary gear 2 has the following relationship:

[0030] ω s =(1+ρ)×ω c -ω r / ρ

[0031] ω c =ρ×ω s / (1+ρ)+ω r / (1+ρ)

[0032] ω r =(1+ρ)×ω c -ρ×ω s

[0033] T s =ρ×T c / (1+ρ)=ρ×T r (1)

[0034] T r =T c / (1+ρ)

[0035] ρ = number of teeth of sun gear / number of teet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com