New type surface mounted permanent magnet synchronous motor with reduced cogging torque

A technology of permanent magnet synchronous motor and cogging torque, which is applied in the direction of magnetic circuits, electric components, electrical components, etc., can solve the problems of excessive no-load back EMF, partial saturation of the temperature field, and unsatisfactory improvement effects, etc., to achieve The effect of reducing dosage, increasing output power and reducing cogging torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

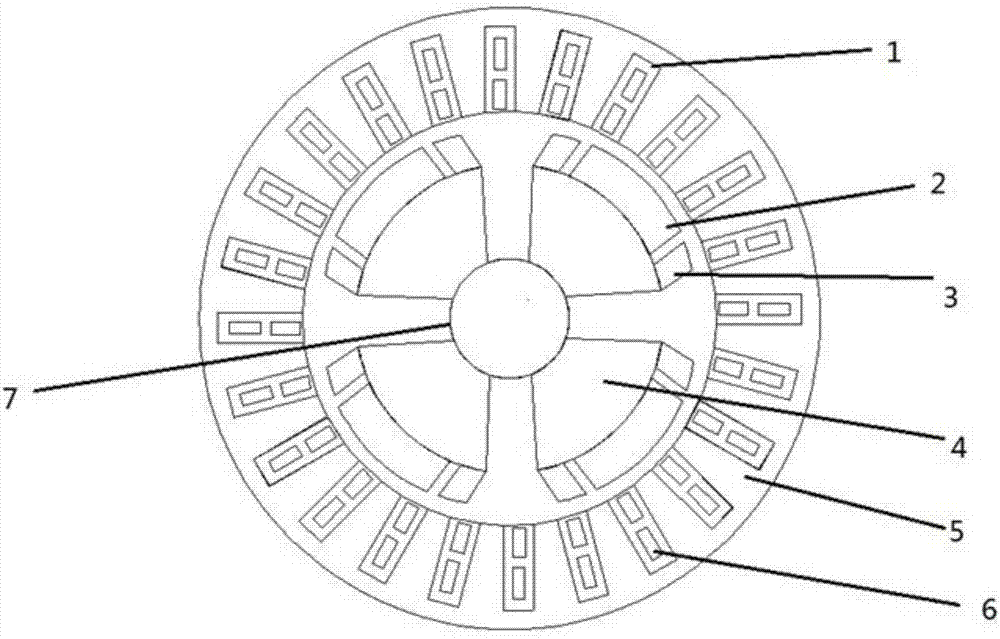

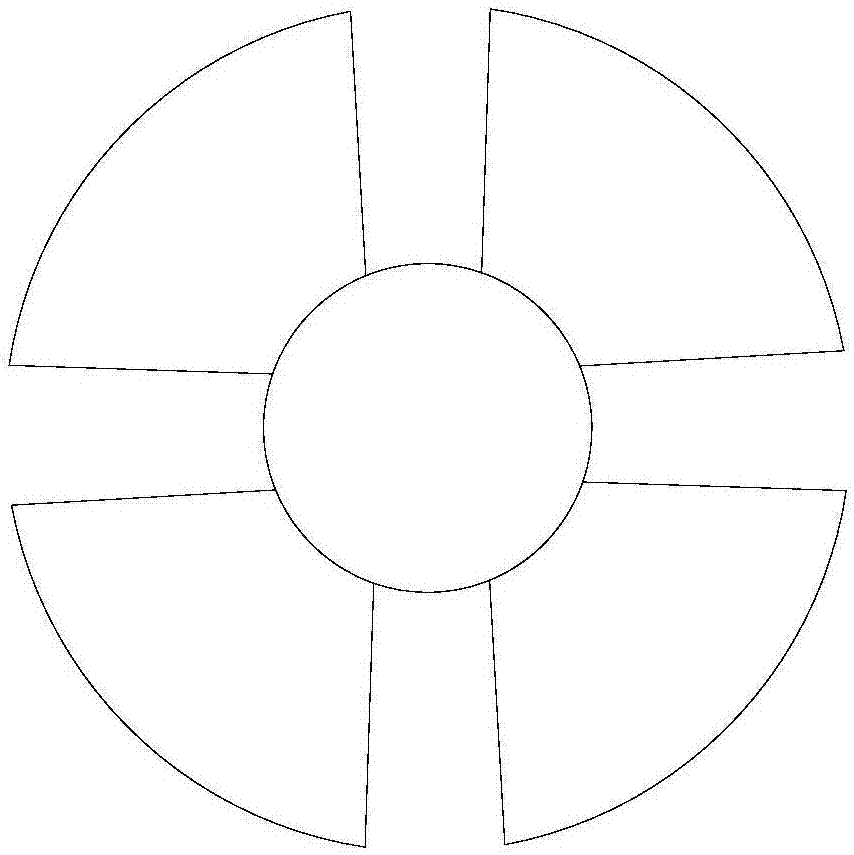

[0018] Such as figure 1 As shown, a new surface-mounted permanent magnet synchronous motor with reduced cogging torque includes a rotor 4 and a stator 5, the stator 5 is provided with a stator slot 1, and the stator slot 1 is provided with a rectangular armature winding 6 (armature winding 6 adopts rectangular windings, which can improve the slot full rate of the motor and is suitable for low-end industrial use); the structure of the rotor 4 is: four evenly distributed fan-shaped rotors 4 are welded on the rotor shaft 7 ( figure 2 ), the permanent magnets on the surface of the fan-shaped rotor 4 are divided into three pieces, and the two ends of the fan-shaped rotor 4 are mounted on the surface with the first permanent magnet 2 of equal size, and the middle surface is mounted on the second permanent magnet 3, and the second permanent magnet 3 is too large The rotor 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com