Permanent magnet type synchronous motor

A technology of synchronous motors and permanent magnets, which is applied in the direction of synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit stationary parts, etc., and can solve problems such as the decrease of stator core magnetic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

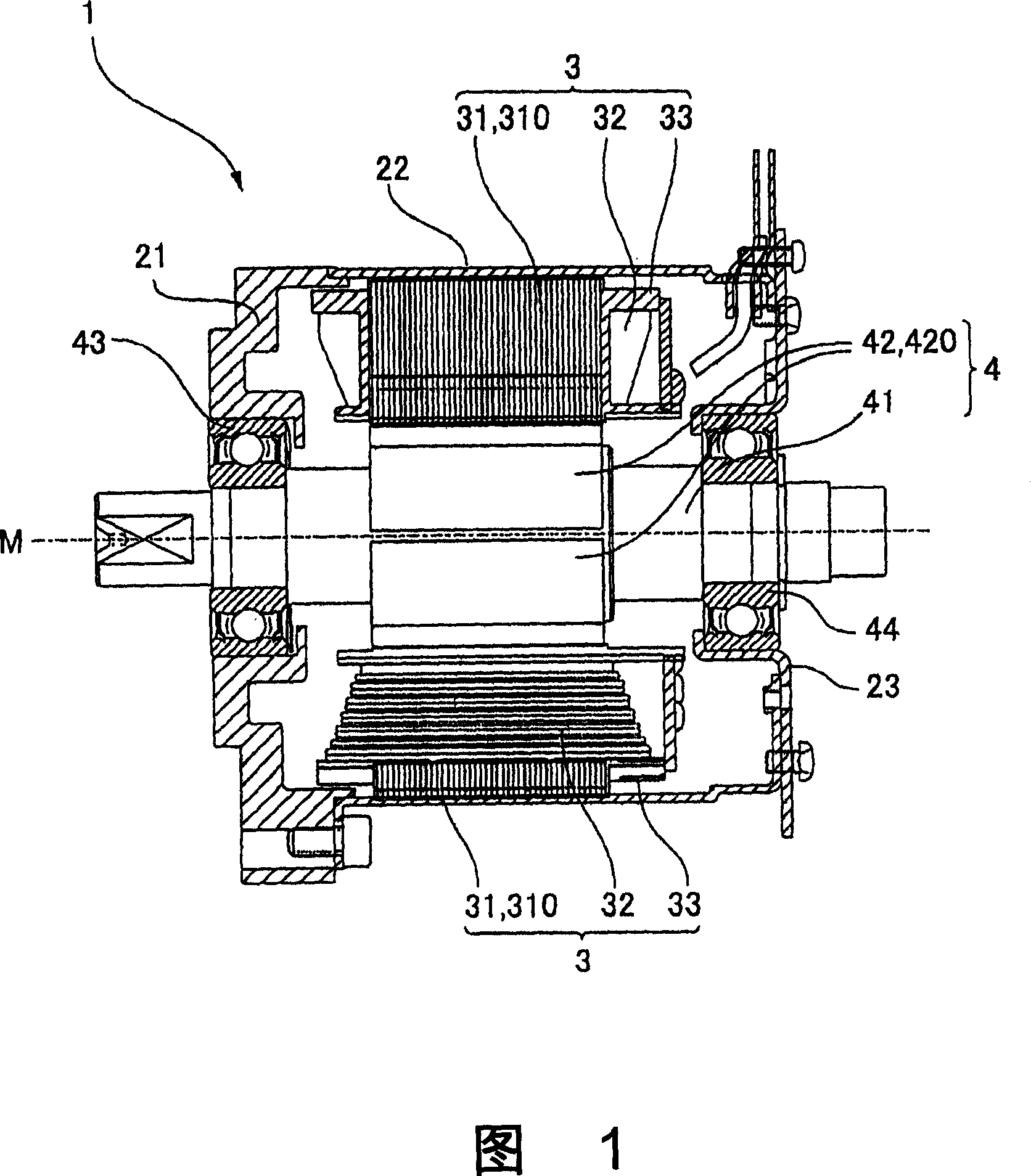

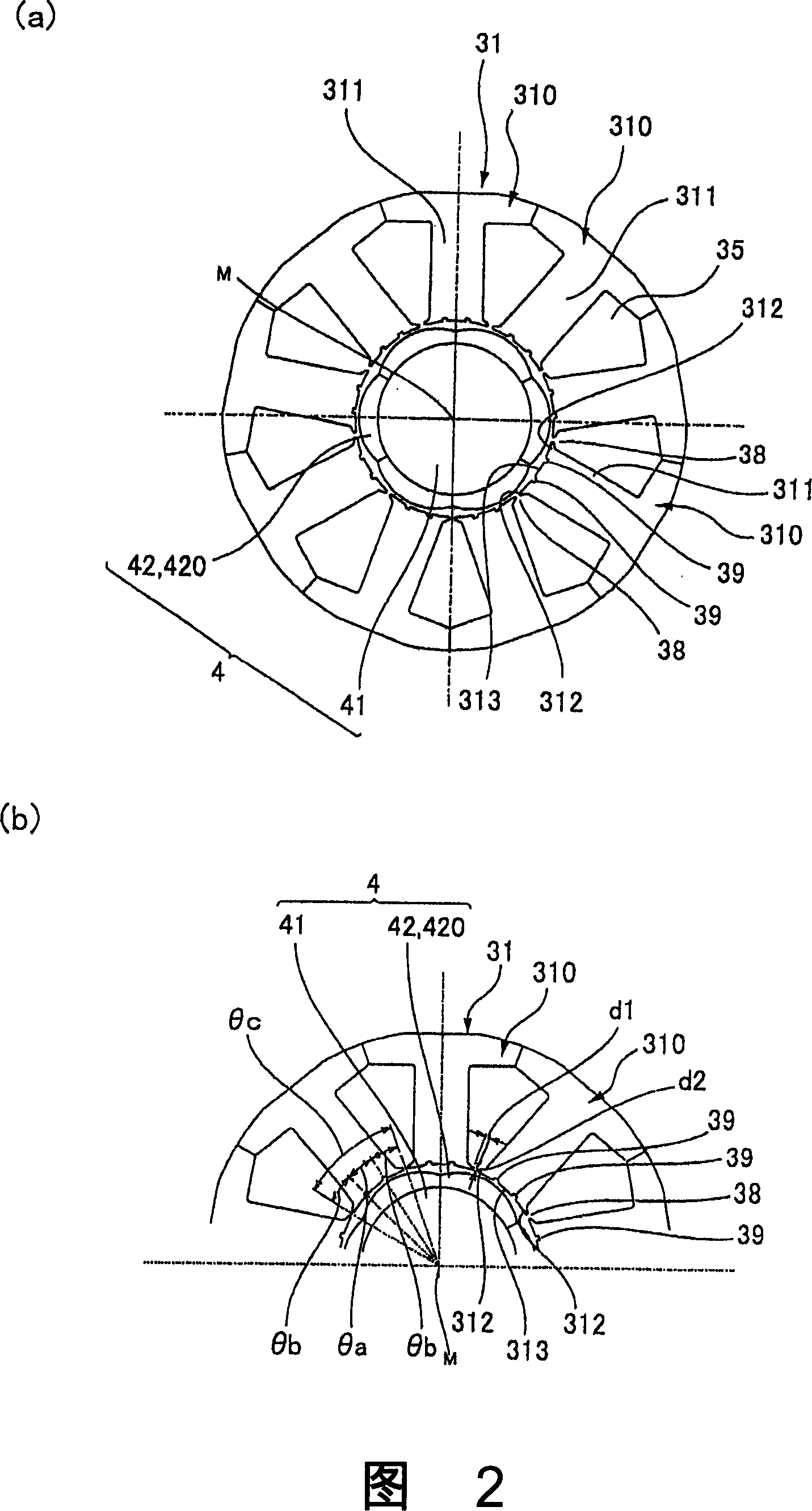

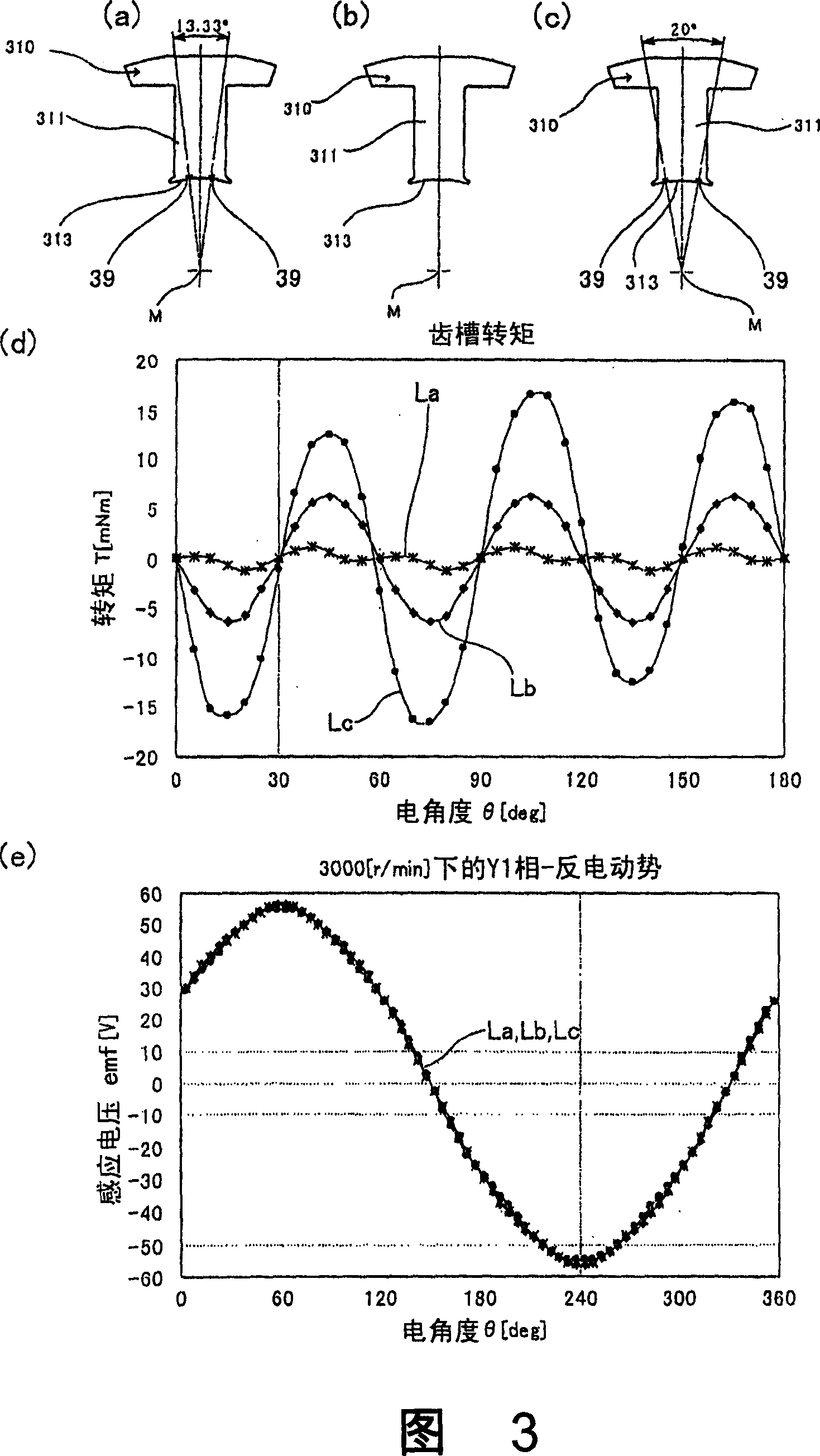

[0033] FIG. 1 is a cross-sectional view showing the configuration of a motor to which the present invention is applied. 2(a) and (b) are a cross-sectional view showing the configuration of a stator core to which the present invention is applied, and an explanatory diagram showing the configuration of an auxiliary slot, respectively.

[0034] (overall composition)

[0035] As shown in FIG. 1 , the motor 1 of this embodiment includes a cylindrical motor case 22 , a stator 3 arranged inside the motor case 22 , and a rotor 4 arranged inside the stator 3 . Both ends of the motor case 22 in the direction of the motor center axis M are open, and the bearing holding member 21 is attached to the motor case 22 so as to cover one of the openings, and the bearing holding member 23 is attached to cover the other opening. on the motor housing 22 . Therefore, the bearing holding member 21 and the bearing holding member 23 are used as housing members. The rotor 4 has a permanent magnet 42 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com