Motor stator device

A motor stator and stator technology, applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problems of not conforming to the user, not easy to automate, and the coil is not so compact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

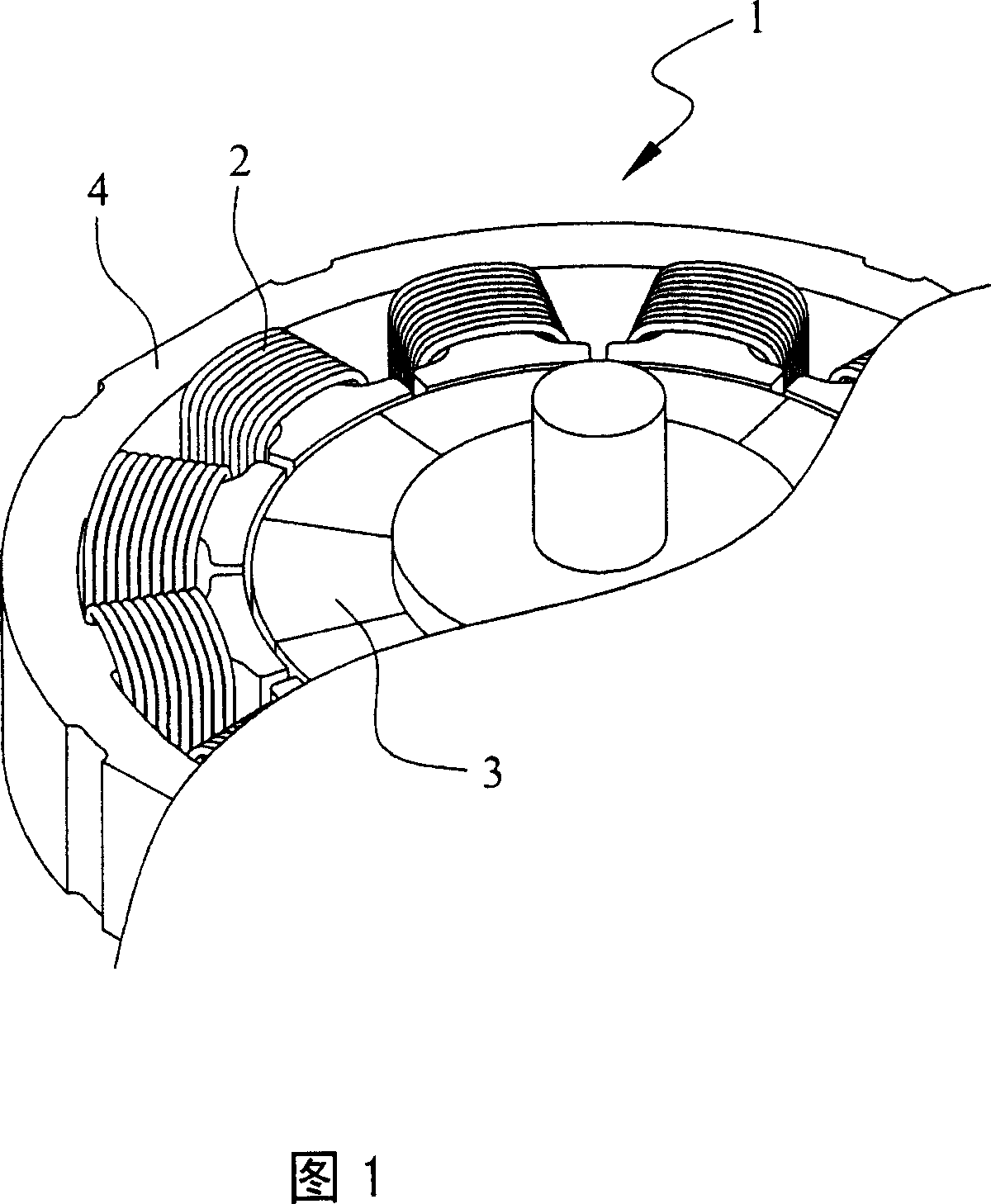

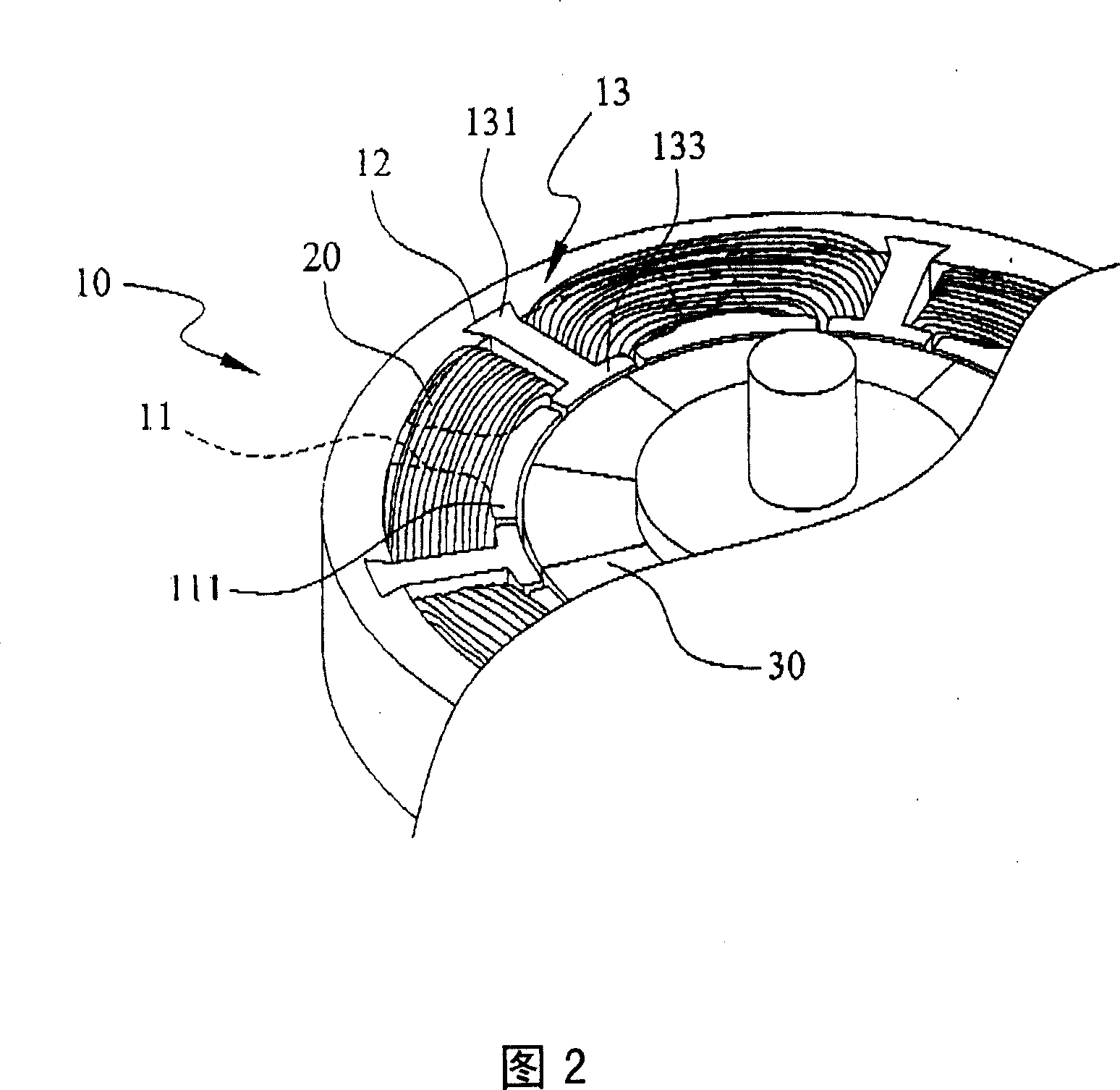

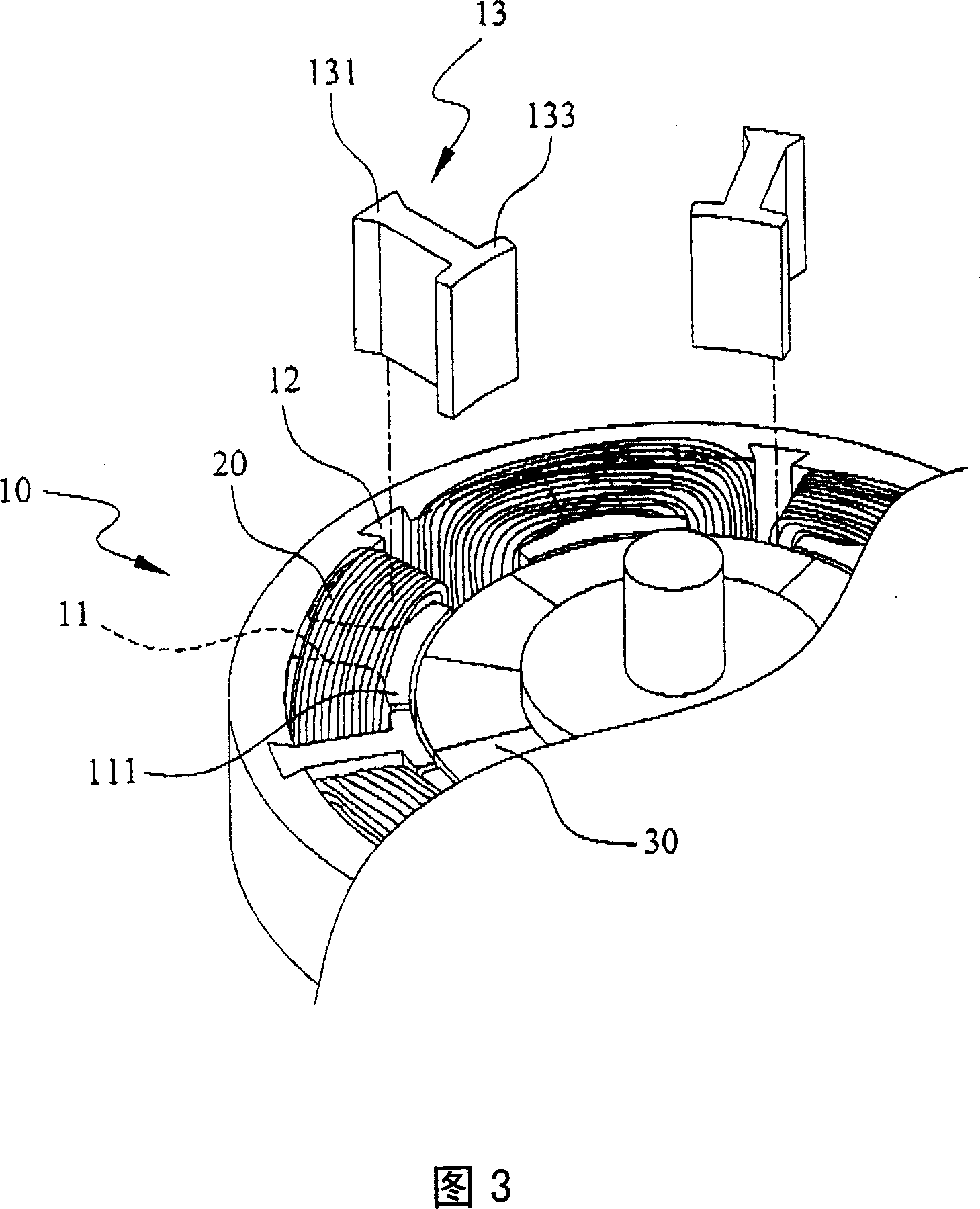

[0026] Please refer to Figures 2 to 4, the present invention is a motor stator device, the motor stator device includes:

[0027] A stator 10, the stator 10 is provided with a plurality of teeth 11, each tooth 11 is provided with an extension 111 at one end, and a positioning groove 12 is provided between two adjacent teeth 11 on the inner wall of the stator 10, each The positioning slot 12 is equipped with a tooth 13, and one end of the tooth 13 is provided with a coupling portion 131 for coupling to the positioning slot 12 on the inner wall of the stator 10, and the other end of the tooth 13 is provided with an extension portion 133, and The extension portion 133 of each tooth 13 is disposed corresponding to the extension portion 111 of each tooth portion 11 .

[0028] A plurality of coils 20 are provided, and each coil 20 is wound around each tooth portion 11 in the stator 10 .

[0029] A rotor 30 (the rotor is a magnet), and the rotor 30 is arranged inside the stator 10 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com