Double upright pole for flat-surface grinding machine

A surface grinder and double-column technology, which is applied in the direction of grinding machines, machine tools suitable for grinding workpiece planes, grinding/polishing equipment, etc., can solve problems such as poor stress state of a single column, reduced grinding accuracy, and influence on column rigidity , to achieve the effects of balanced stress state, improved grinding precision and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

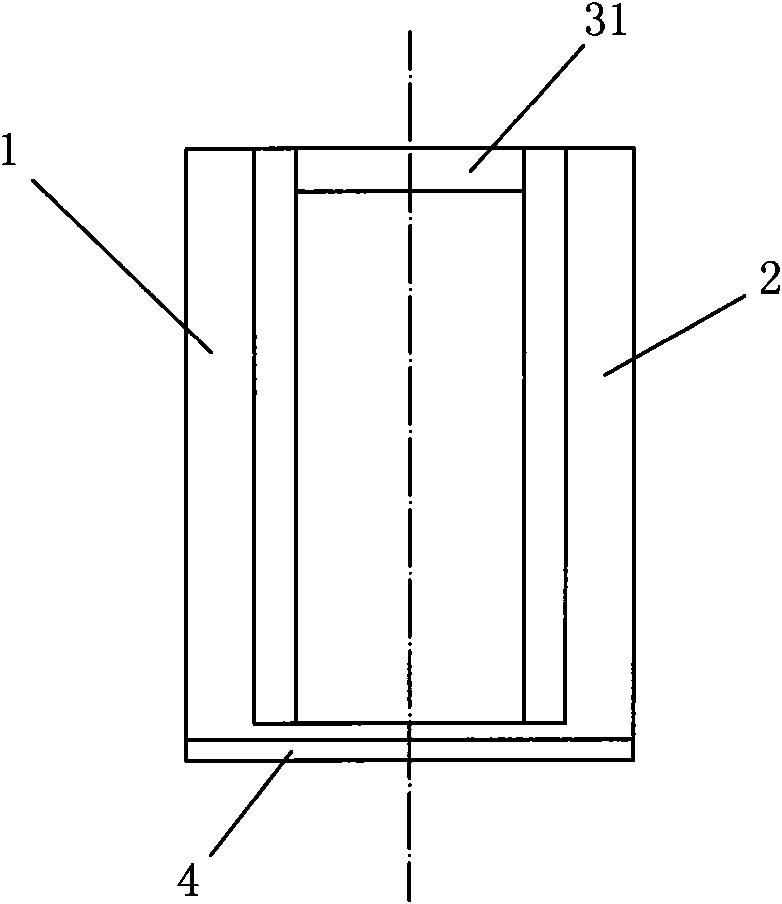

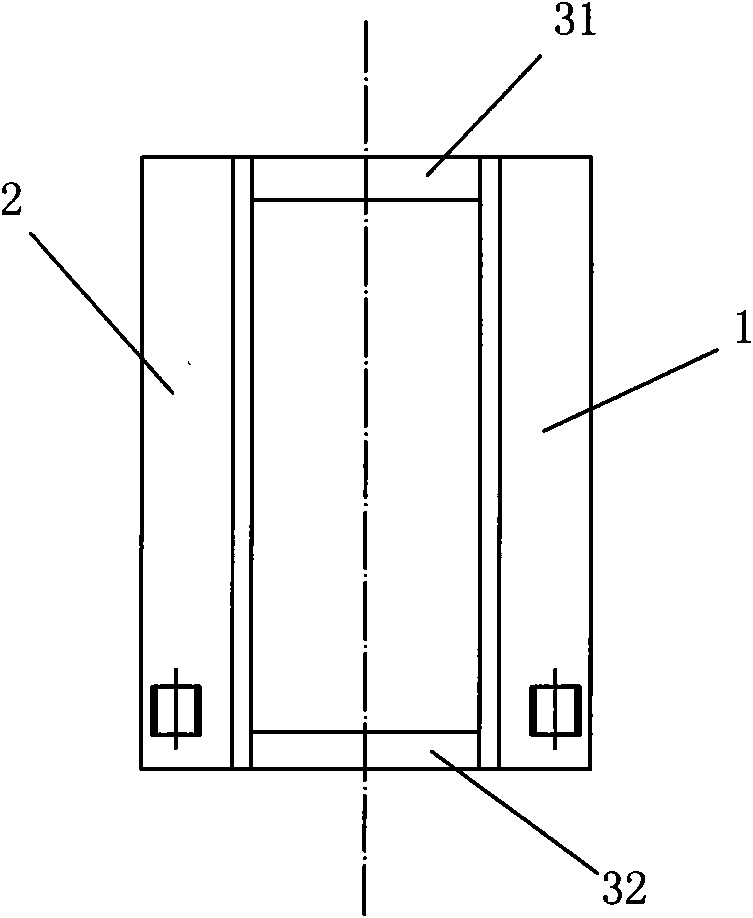

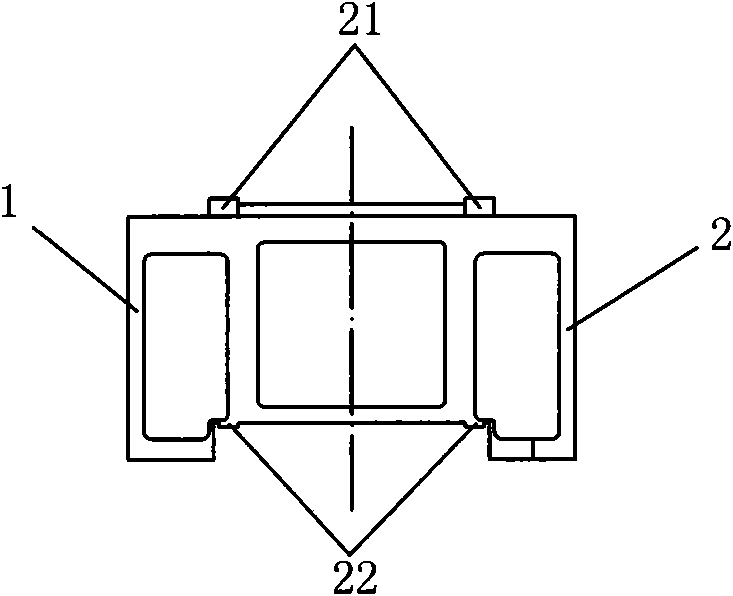

[0015] see Figure 1~3 , the present invention is provided with 2 identical hollow columns 1 and 2, column bottom plate 4, 2 sets of guide rails 21 and 22, upper end transverse reinforcing rib 31 and lower end transverse reinforcing rib 32. Two columns 1 and 2 are identical in structure and parallel, 2 Root columns 1 and 2 are fixed on the column bottom plate 4. Two sets of guide rails 21 and 22 are arranged on the front and back sides of the two columns 1 and 2 respectively, and the two sets of guide rails 21 and 22 are parallel to each other and arranged along the vertical direction of the two columns 1 and 2 . The upper transverse reinforcing rib 31 and the lower transverse reinforcing rib 32 are both arranged between the two columns 1 and 2, the upper transverse reinforcing rib 31 connects the upper ends of the two columns 1 and 2, and the lower transverse reinforcing rib 32 connects the two columns 1 and 2. The lower end of 2 is connected.

[0016] see Figure 4 , when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com