Flip transparent reelable flexible film LED display screen and production process thereof

An LED display and production process technology, applied in the field of flexible screens, can solve the problems of large-scale display, long life, and increased production costs, and achieve the effects of good display consistency, improved production efficiency, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

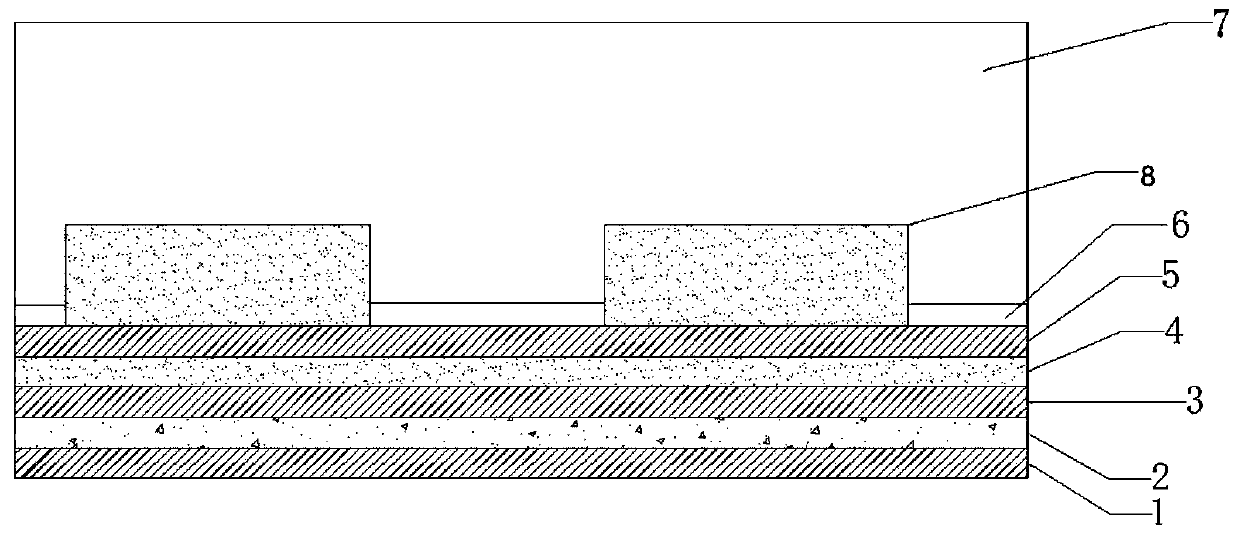

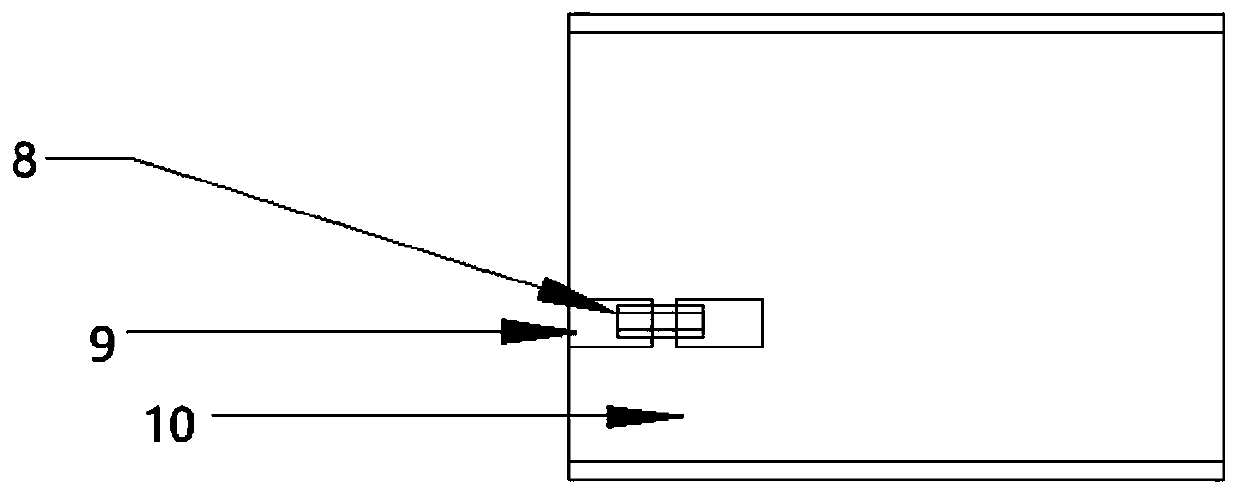

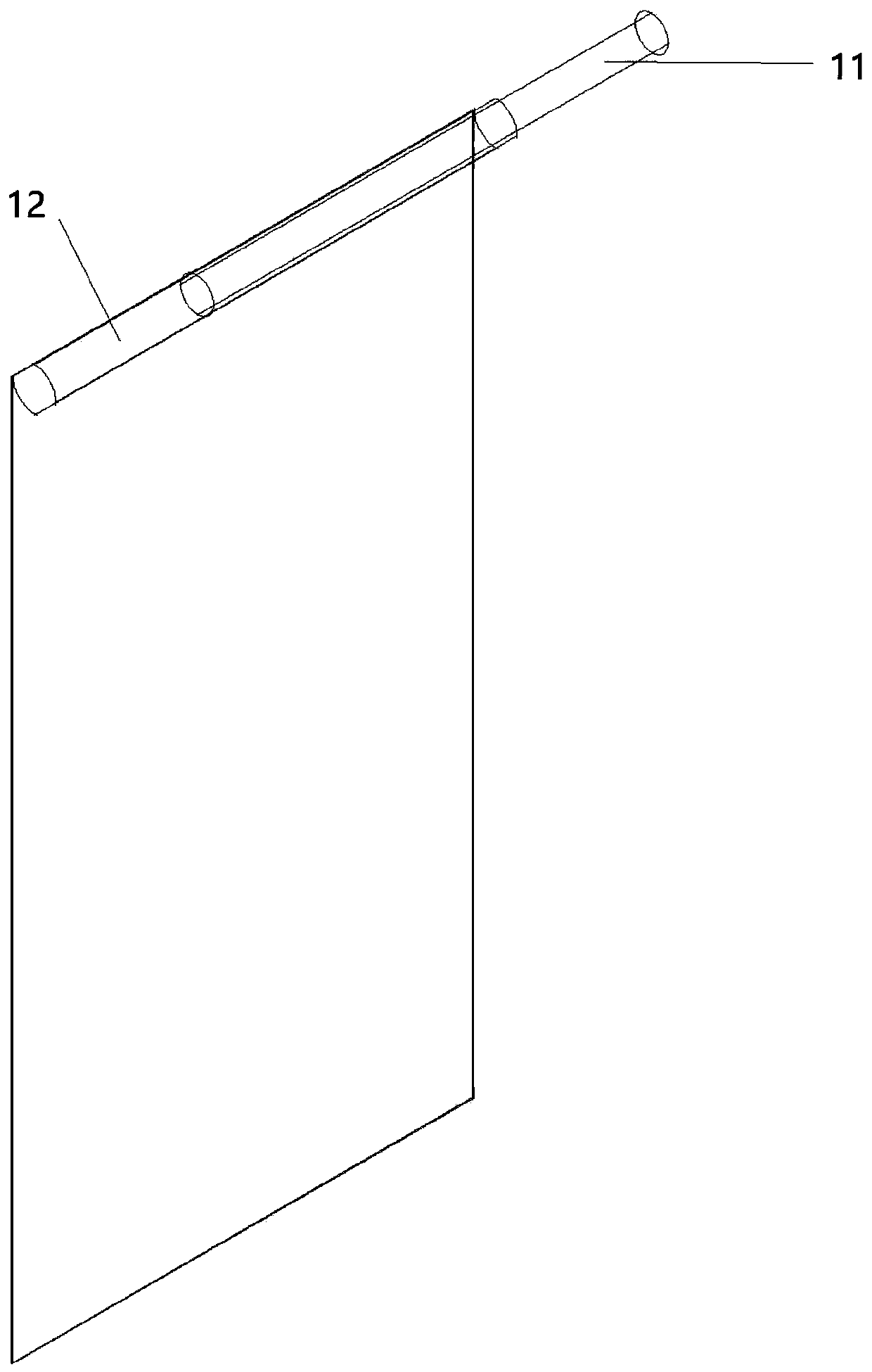

[0031] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0032] The present invention uses a transparent flexible high-temperature-resistant film as the base material, and sets two circuit layers at different levels as the conductive medium to replace the conventional printed circuit board, and connects the first circuit layer and the second circuit layer through perforation. Together, realize the Unicom of the line; then use the pad to connect the flip-chip LED chip, solder the LED chip on the FPC flexible circuit board, and install multiple LED chips to form a display screen. Since the shape of the transparent flexible film can be changed and bent, even Folding, in terms of transportation and display, can reach the level that the current LED display cannot achieve, and at the same time use the pads to realize the splicing of multiple LED displays, and realize the infin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com