Movable working device, in particular mobile crane

A mobile crane, working machine technology, applied in the field of cantilever and counterweight systems, mobile cranes, can solve problems such as tilt hazards, and achieve the effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

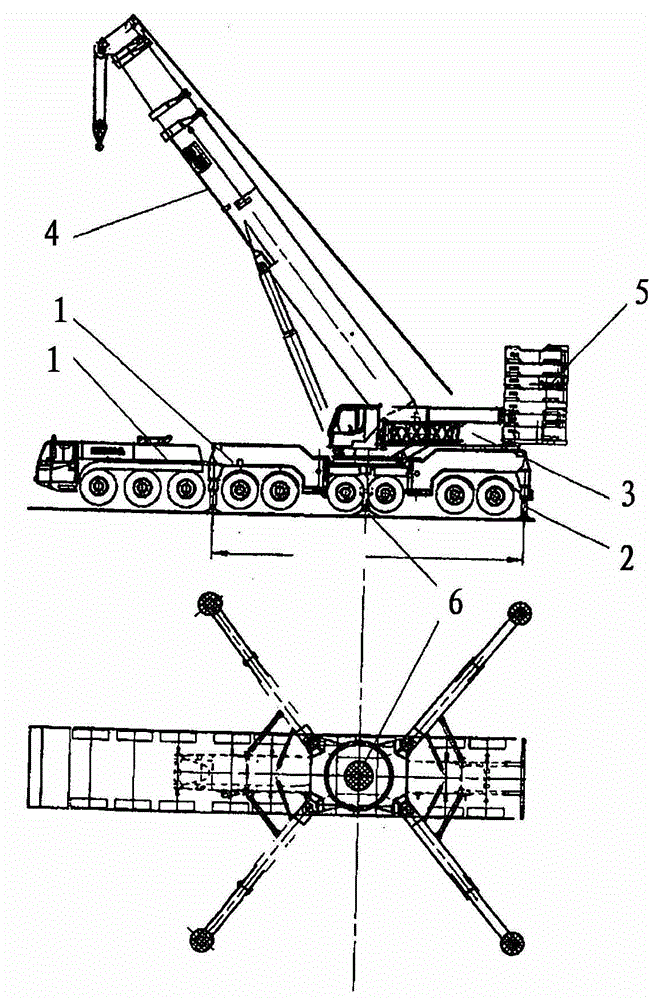

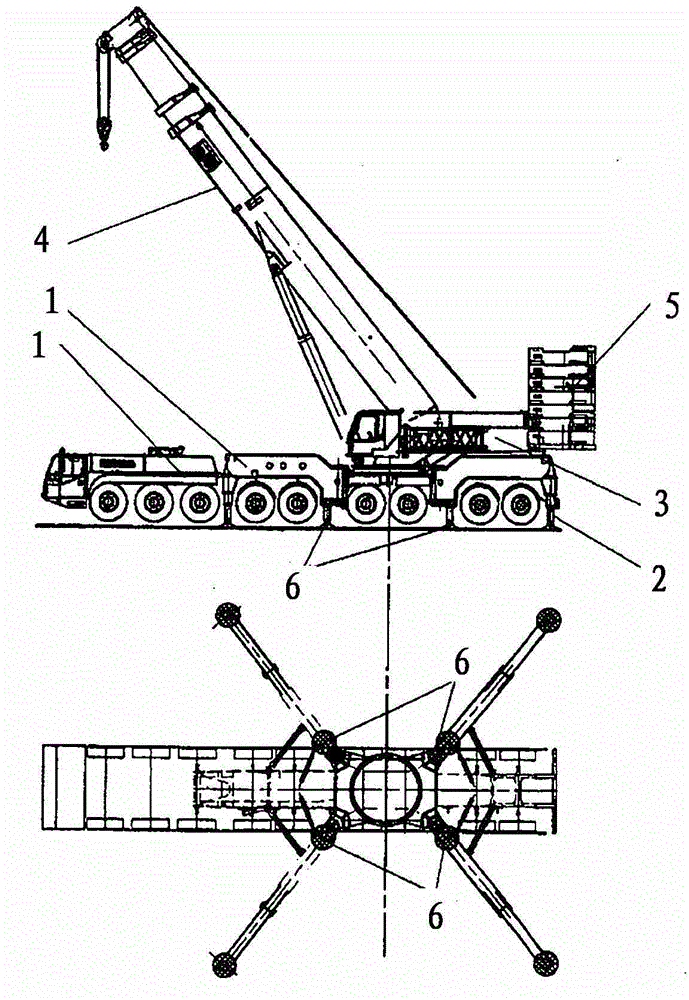

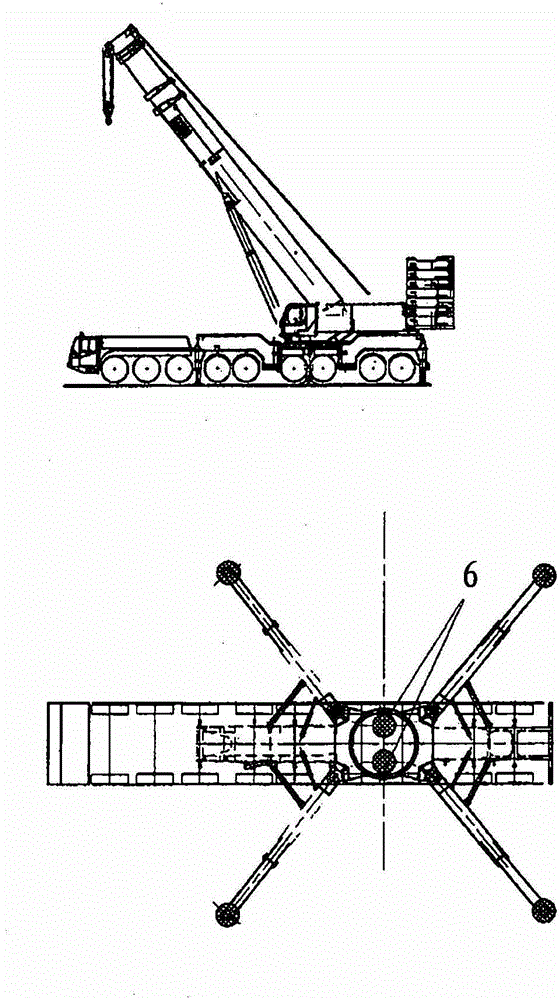

[0033] Example 1 ( figure 1 ) in such a way that a further support cylinder 6 with a support force acquisition device 10 is arranged as a central support centrally below the swivel bearing, said support cylinder being hydraulically adjusted corresponding to the desired support force and Thus receiving a vertical load.

[0034] Here, according to the invention, the operator can use the operating unit 7, 8 ( Figure 4 ) predetermines the desired state of preparation and the activation and boundary conditions of the central support or constraints for standard supports.

[0035] This information is transmitted to the crane control unit / CPU 9 and used to check and display the desired load capacity or to generate a possible new load capacity depending on the limited supporting force. Then, by confirming the displayed application conditions, this type of operation is activated and a corresponding supporting action is exerted hydraulically on the central support via the hydraulic pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com