Concentric hoisting method for T-shaped reinforcement cage with diaphragm walls

A hoisting method and technology for steel cages, which are applied in sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of large economic investment, difficulty in entering steel cages into grooves, and collapse of groove walls, so as to ensure project quality and good economic benefits. , to avoid the effect of sediment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

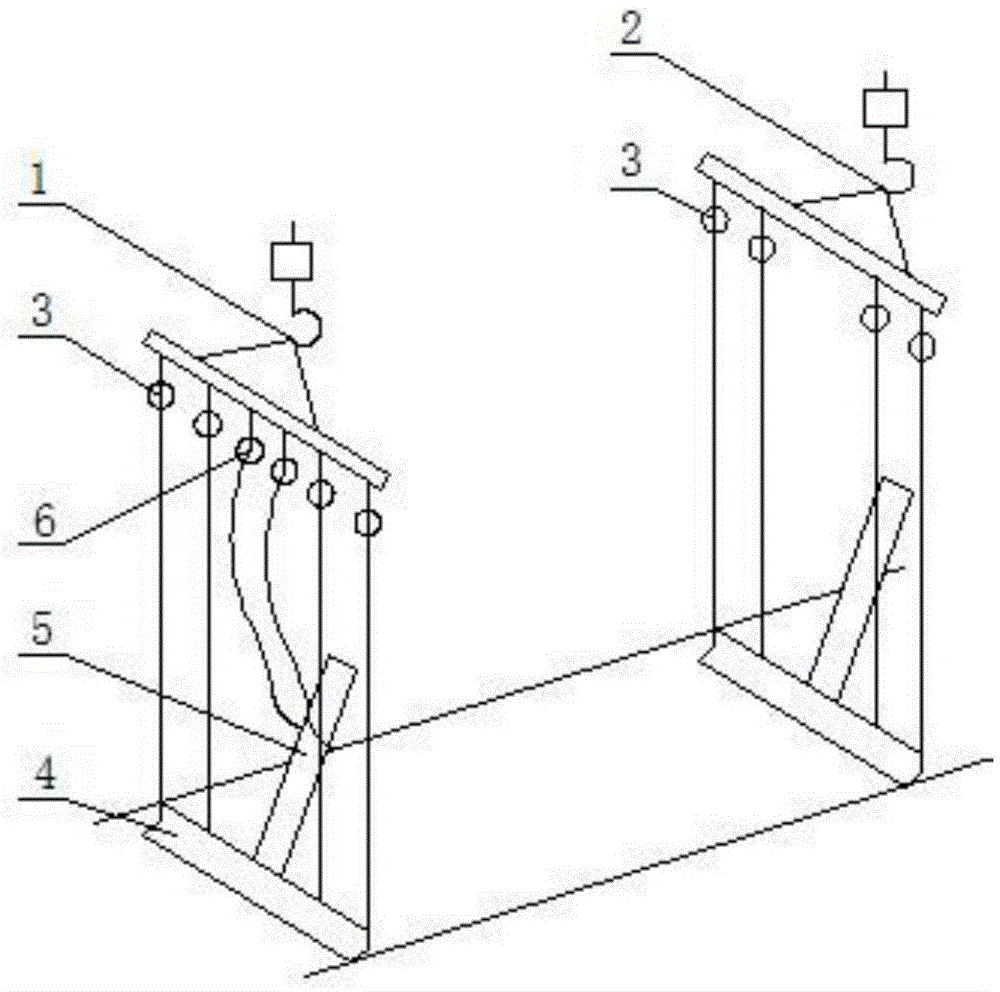

[0019] Such as figure 1 As shown, a concentric hoisting method of a T-shaped ground-connected wall reinforcement cage includes a main sling 1 and an auxiliary sling 2, the two sides of the main sling 1 are 2-6 lifting buckles 3, and the center of the main sling 1 is 2 control buckles 6, the auxiliary sling 2 is the lifting buckle 3, the lifting buckle 3 of the main sling 1 is the sling tied on the wing wall 4, and the control buckle 6 is the sling tied on the abdominal wall 5.

Embodiment 2

[0021] Such as figure 1 As shown, a concentric hoisting method of a T-shaped ground-connected wall reinforcement cage includes a main sling 1 and an auxiliary sling 2. There are 4 lifting buckles 3 on both sides of the main sling 1, and 2 lifting buckles 3 on the left and right sides. The center of the main sling 1 is two control buckles 6, the auxiliary sling 2 is the lifting buckle 3, the lifting buckle 3 of the main sling 1 is the sling tied to the wing wall 4, and the control buckle 6 is tied to the wing wall 4. For the sling on the abdominal wall 5, the lifting buckle 3 is stressed at the same time, and the control buckle 6 is not stressed, and continues to turn over until the control buckle 6 is stressed, and the reinforcement cage is in a vertical state at this moment.

[0022] With the above technical scheme, only two control buckles are added to the main sling 1, the economic investment is small, and the operation is simple and easy. Therefore, the sediment at the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com