Low-cholesterol and low-acid value beef tallow and preparation method thereof

A low-cholesterol, low-acid value technology, applied in the direction of fat oil/fat refining, fatty acid esterification, fat oil/fat production, etc., can solve the problems of high cholesterol and acid value, loss of flavor, etc. , The effect of nutrient loss is not easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of low-cholesterol and low-acid value tallow provided by the preferred embodiment of the present invention, the specific method of its preparation is as follows:

[0035] (1) Use beef fat that has passed the inspection as raw material, wash and dry it with water that meets food safety, and perform quick freezing at a temperature of -21°C to -19°C, and use a grinder to chop the beef fat to obtain Beef fat cubes.

[0036] (2) Gradient temperature cooking: Boil the beef fat block obtained by crushing at an initial temperature of 100°C, raise the temperature every 15 minutes, increase the temperature to 10°C each time, and finally heat up to 200°C and boil for 30 minutes. Liquid separation to obtain boiled wool butter.

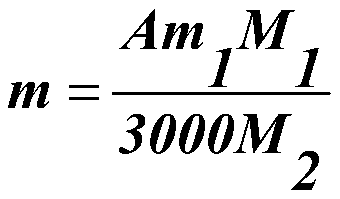

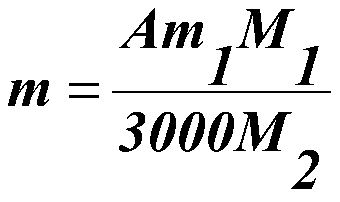

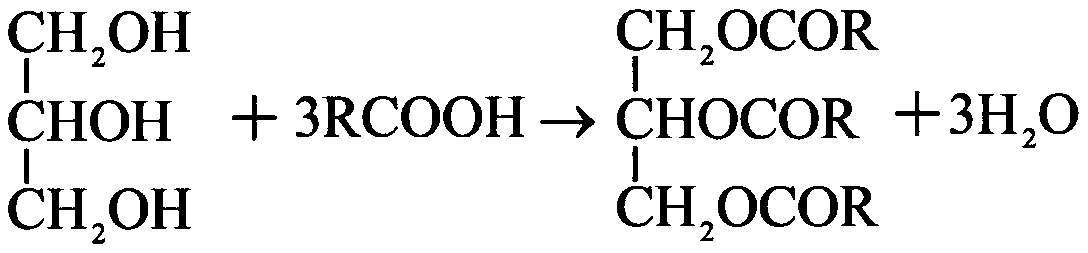

[0037] (3) Lower cholesterol: lower the temperature of the crude butter oil obtained in the above step (2) to 50°C to 60°C, add immobilized cholesterol oxidase, the amount of cholesterol oxidase added is 3% of the mass of butter, and the enzymatic h...

Embodiment 2

[0045] A kind of low-cholesterol and low-acid value tallow provided by the preferred embodiment of the present invention, the specific method of its preparation is as follows:

[0046] (1) Use beef fat that has passed the inspection as raw material, wash and dry it with water that meets food safety, and perform quick freezing at a temperature of -21°C to -19°C, and use a pulverizer to cut and pulverize the beef fat to obtain Beef fat cubes.

[0047] (2) Gradient temperature cooking: Boil the beef fat block obtained by crushing at an initial temperature of 100°C, raise the temperature every 15 minutes, increase the temperature to 10°C each time, and finally heat up to 200°C and boil for 30 minutes. Liquid separation to obtain boiled wool butter.

[0048] (3) Lower cholesterol: lower the temperature of the crude butter oil obtained in the above step (2) to 50°C to 60°C, add immobilized cholesterol oxidase, the amount of cholesterol oxidase added is 2% of the mass of butter, and t...

Embodiment 3

[0056] A kind of low-cholesterol and low-acid value tallow provided by the preferred embodiment of the present invention, the specific method of its preparation is as follows:

[0057] (1) Use beef fat that has passed the inspection as raw material, wash and dry it with water that meets food safety, and perform quick freezing at a temperature of -21°C to -19°C, and use a pulverizer to cut and pulverize the beef fat to obtain Beef fat cubes.

[0058] (2) Gradient temperature cooking: Boil the beef fat block obtained by crushing at an initial temperature of 100°C, raise the temperature every 15 minutes, increase the temperature to 10°C each time, and finally heat up to 200°C and boil for 30 minutes. Liquid separation to obtain boiled wool butter.

[0059] (3) Lower cholesterol: reduce the temperature of the crude butter oil obtained in the above step (2) to 50°C to 60°C, add immobilized cholesterol oxidase, the amount of cholesterol oxidase added is 4% of the mass of butter, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com