Preparation method of enzymolysis buckwheat flour

A technology of buckwheat flour and enzymatic hydrolysis, which is applied in the field of preparation of enzymatic buckwheat flour, can solve the problems of jelly and other problems, and achieve the effect of improving storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

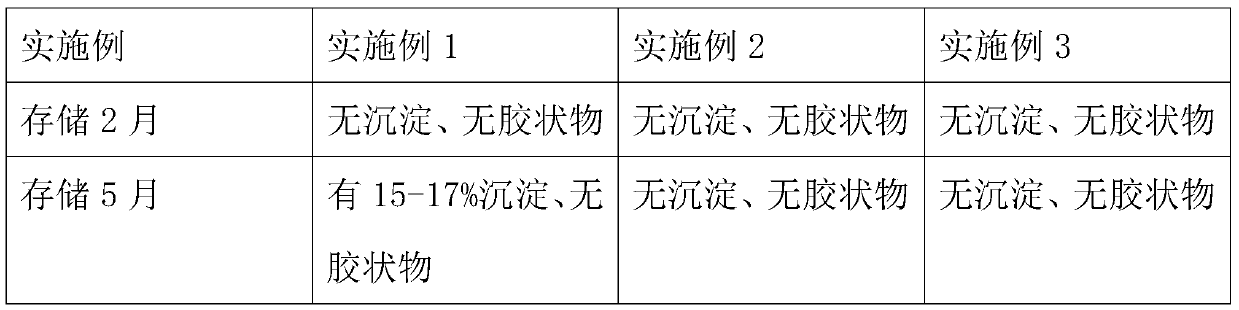

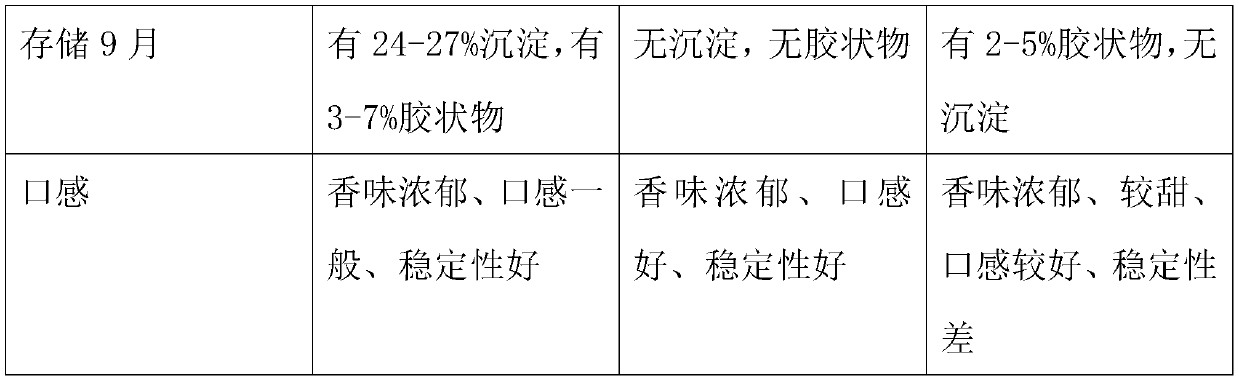

Embodiment 1

[0020] The preparation method is as follows:

[0021] Step 1: Prepare raw materials, 10 parts of buckwheat flour, 0.01 part of β-amylase, 0.01 part of lactic acid, 0.01 part of hydrochloric acid, 0.01 part of sodium hydroxide, 0.2 part of 3,5-dinitrosalicylic acid and 0.2 part of glucose;

[0022] Step 2: Mix the buckwheat flour with water and finely grind it into a slurry;

[0023] Step 3: cooking the slurry mixture;

[0024] Step 4: After stopping the heating, add β-amylase, lactic acid, hydrochloric acid and sodium hydroxide for stirring to obtain slurry-like enzymatic buckwheat flour;

[0025] Step 5: Put the slurry-like buckwheat flour into a dryer, add 3,5-dinitrosalicylic acid and glucose, stir and dry to obtain dry enzymatic buckwheat flour.

[0026] Wherein, the ratio of buckwheat flour to water in step 2 is 1:8.

[0027] Wherein, the cooking temperature in step 3 is between 90-110°C.

[0028] Wherein, the temperature when adding β-amylase, lactic acid, hydrochlor...

Embodiment 2

[0031] The preparation method is as follows:

[0032] Step 1: Prepare raw materials, 20 parts of buckwheat flour, 0.02 part of β-amylase, 0.02 part of lactic acid, 0.02 part of hydrochloric acid, 0.02 part of sodium hydroxide, 0.4 part of 3,5-dinitrosalicylic acid and 0.4 part of glucose;

[0033] Step 2: Mix the buckwheat flour with water and finely grind it into a slurry;

[0034] Step 3: cooking the slurry mixture;

[0035] Step 4: After stopping the heating, add β-amylase, lactic acid, hydrochloric acid and sodium hydroxide for stirring to obtain slurry-like enzymatic buckwheat flour;

[0036] Step 5: Put the slurry-like buckwheat flour into a dryer, add 3,5-dinitrosalicylic acid and glucose, stir and dry to obtain dry enzymatic buckwheat flour.

[0037] Wherein, the ratio of buckwheat flour to water in step 2 is 1:8.

[0038] Wherein, the cooking temperature in step 3 is between 90-110°C.

[0039] Wherein, the temperature when adding β-amylase, lactic acid, hydrochlor...

Embodiment 3

[0042] The preparation method is as follows:

[0043] Step 1: Prepare raw materials, 30 parts of buckwheat flour, 0.03 part of β-amylase, 0.03 part of lactic acid, 0.03 part of hydrochloric acid, 0.03 part of sodium hydroxide, 0.6 part of 3,5-dinitrosalicylic acid and 0.6 part of glucose;

[0044] Step 2: Mix the buckwheat flour with water and finely grind it into a slurry;

[0045] Step 3: cooking the slurry mixture;

[0046] Step 4: After stopping the heating, add β-amylase, lactic acid, hydrochloric acid and sodium hydroxide for stirring to obtain slurry-like enzymatic buckwheat flour;

[0047] Step 5: Put the slurry-like buckwheat flour into a dryer, add 3,5-dinitrosalicylic acid and glucose, stir and dry to obtain dry enzymatic buckwheat flour.

[0048] Wherein, the ratio of buckwheat flour to water in step 2 is 1:8.

[0049] Wherein, the cooking temperature in step 3 is between 90-110°C.

[0050] Wherein, the temperature when adding β-amylase, lactic acid, hydrochlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com