Injection valve for 4 stroke engine

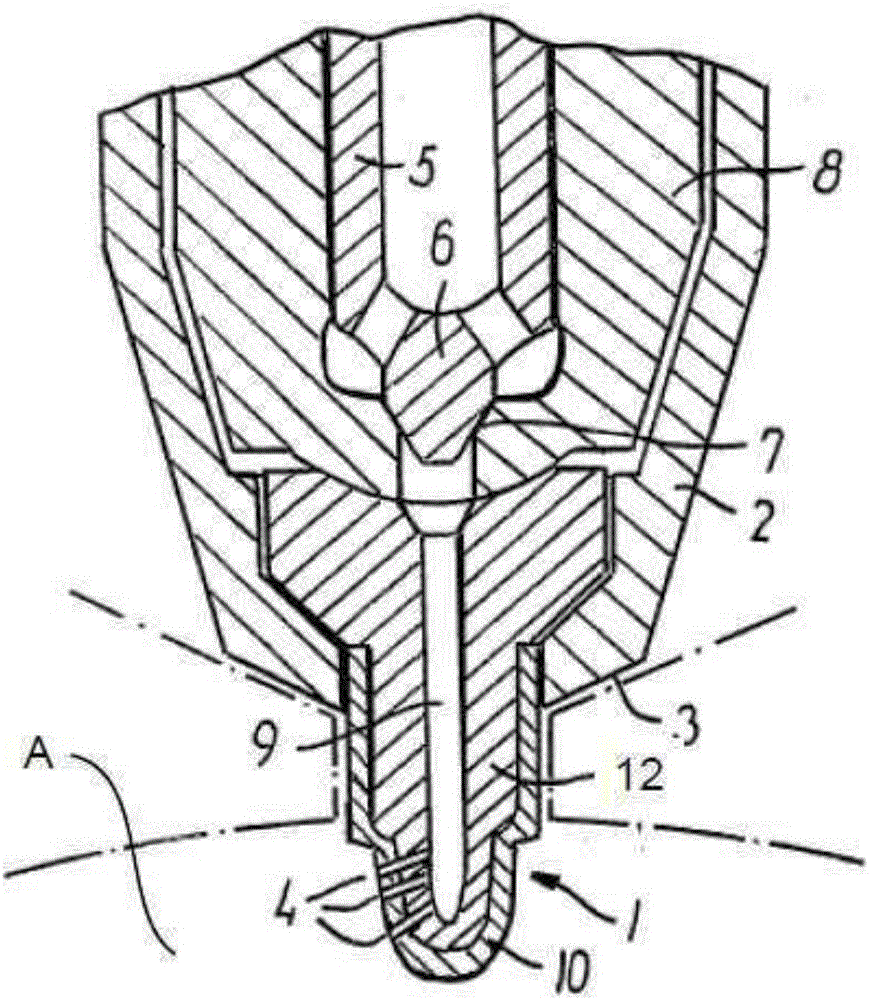

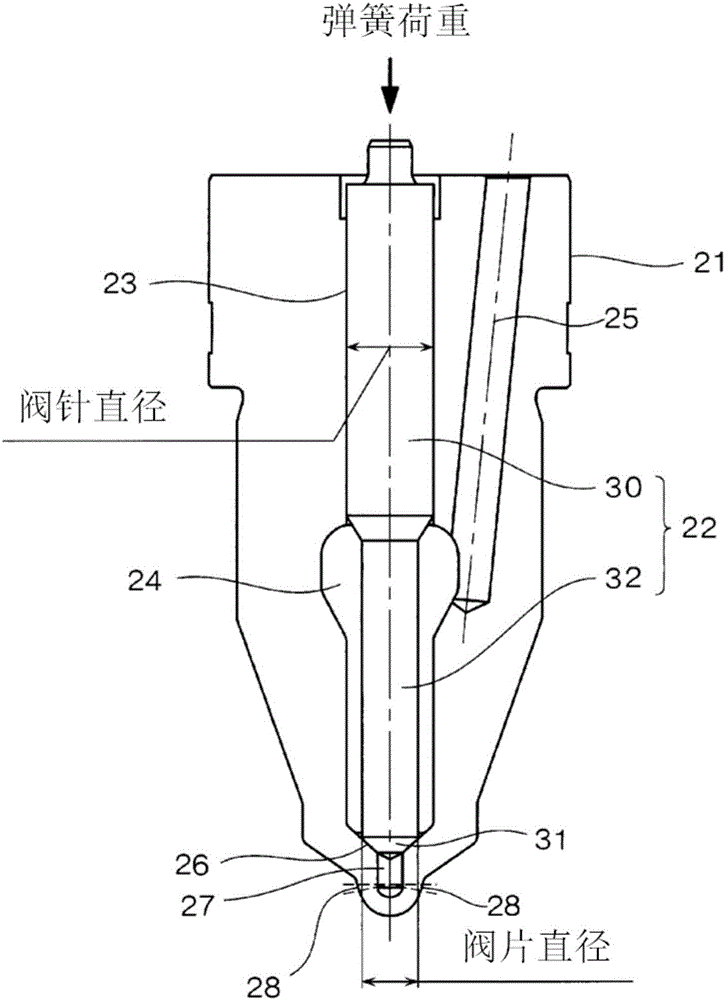

An injection valve, four-stroke technology, used in fuel injection devices, engine components, machines/engines, etc., can solve the problems of reduced thermal efficiency and fuel consumption rate, deviation of spray characteristics of injection holes, and improved compression ratio. Improves wear resistance and prevents decarburization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

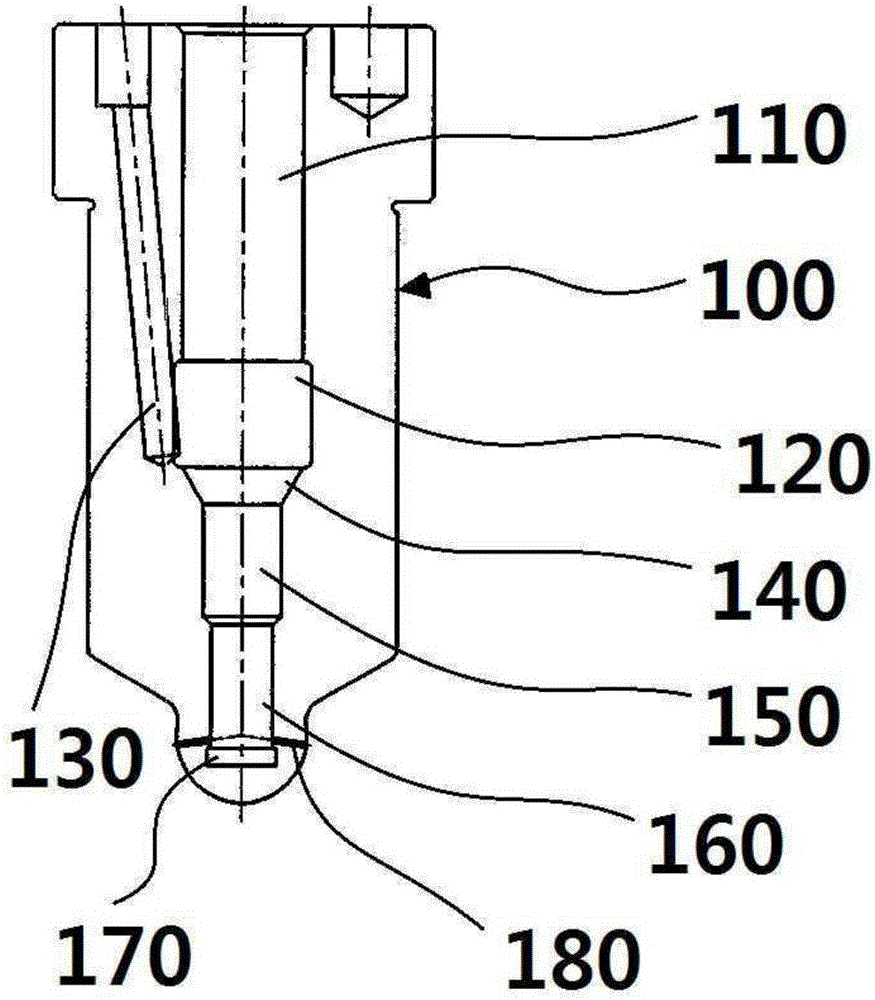

[0036] Hereinafter, the present invention will be described in more detail with reference to the drawings.

[0037] image 3 It is a drawing showing a stamped retainer of a four-stroke injection valve according to a first embodiment of the present invention.

[0038] According to the injection valve of the present invention, it includes: a stamping cage (100), formed with a punch rod (200; refer to Figure 4 ) sliding hole; punch rod (200; refer to Figure 4 ), is inserted into the slide hole and slides to control fuel injection.

[0039] The sliding hole formed in the stamped cage (100) is composed in order from the top: a base sliding hole (110) with a first diameter, a first fuel chamber (120) with a second diameter larger than the first diameter, and a second fuel chamber (120) from the bottom. 1 The farther the fuel chamber (120) is, the tapered first opening and closing surface (140) with a smaller diameter, the second fuel chamber (150) with a third diameter smaller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com